- 40 -

Accumulator gas charging pressure:

Hammer model

CHARHING

at ambient temperature;

20°C (68°F)

CHECKING

at operating temperature;

60~70°C (140~158°F)

bar

(psi)

bar

(psi)

PRB170

PRB200

PRB250

PRB300

PRB400

PRB500

PRB700

60

±

2

(870

±

30)

68

±

2

(990

±

30)

7.6. Chisel, wear bushings and

chisel pins

Operating the hammer, even though it is regular

and correct, wear the chisel and its wear parts such

as:

Wear bushings; chisel bush, front bush

Thrust ring

Chisel pin, stop pins and PU-sleeves

Wiper and wiper retainer (for SA version only)

These wear of chisel and wear parts is caused by:

Wear by metal-to-metal sliding

Tear of contact point by micro-welding

Particle engaged abrasive wear

Collapse or peeling of surface by extremely high

contact pressure

Heat generated by friction accelerates wear

Check the chisel, chisel bush and front bush for

wear every 50 hours of hydraulic hammer use or

weekly. And, replace them if the amounts of wear

exceed the permissible wear limits.

If these parts are used beyond their wear limits, the

piston and chisel may be damaged severely.

Especially, when the hydraulic hammer has too

much clearance between the chisel and both wear

bushes, the chisel can be broken by bending

through wrong impacts.

Replacement of the parts below due to wear is not

covered by the warranty.

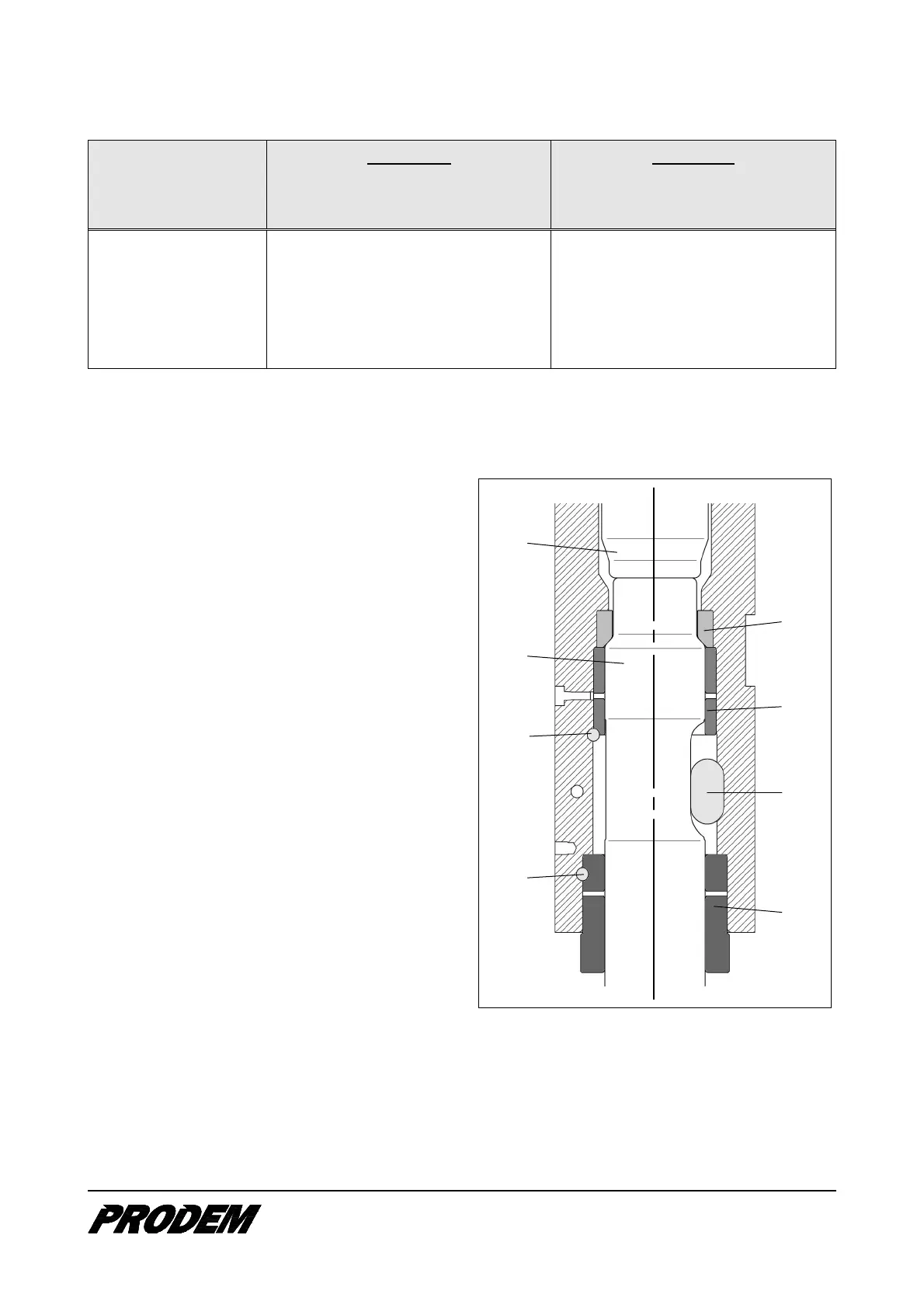

Chisel and wear parts in the front-head:

This is a general angled section view of front-head.

1. Piston 2. Chisel 3. Thrust ring

4. Chisel bush 5. Front bush 6. Chisel pin

7. Stop pin

2

7

7

3

4

6

5

1

Loading...

Loading...