- 32 -

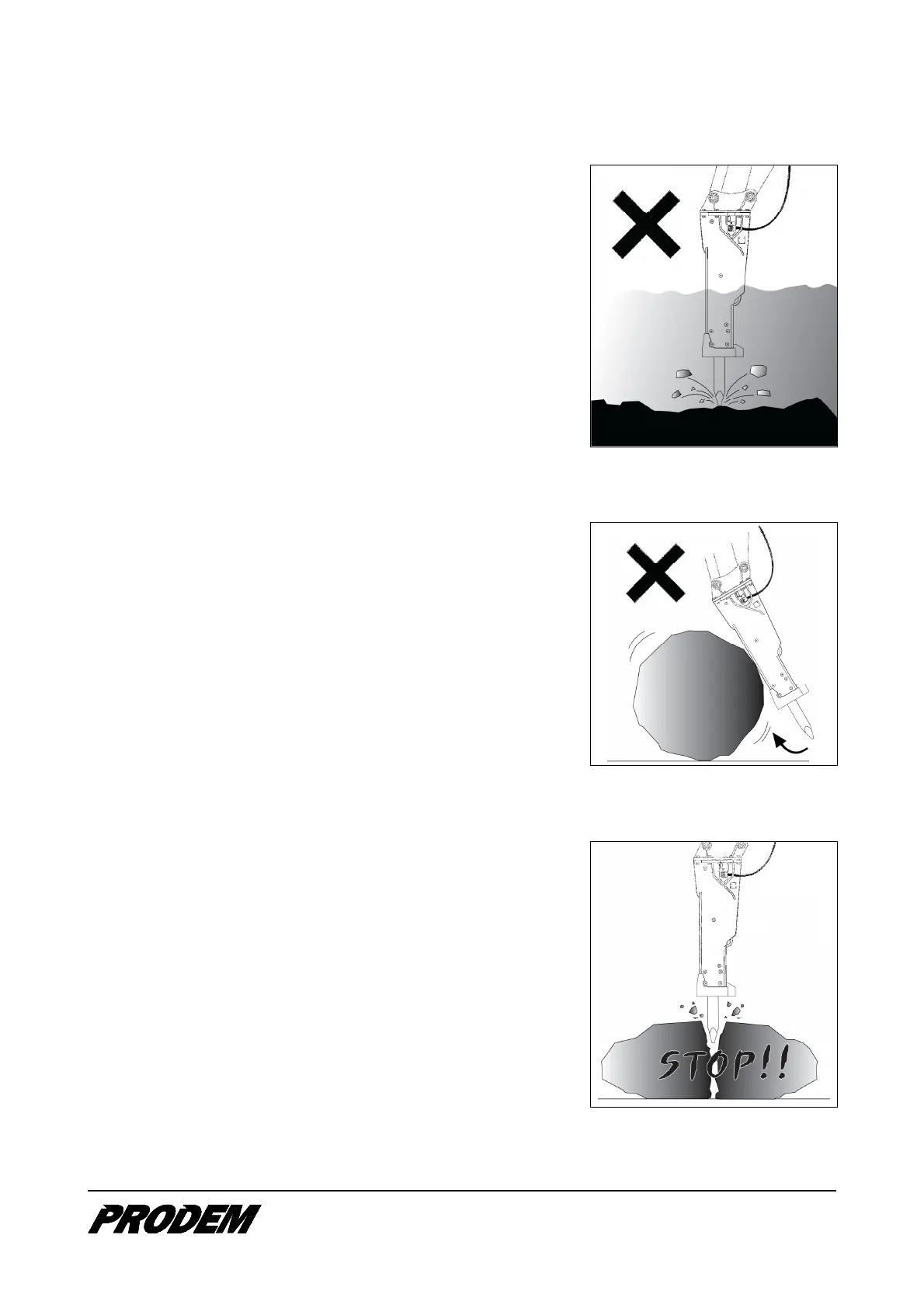

Never use the hydraulic hammer under water:

The hydraulic hammer, as a standard assembly, must never be used in

or under water without prior conversion. If you use under water, water

fills the impact chamber between the piston and the chisel, a strong

hydraulic pressure wave is generated and will damage the seals in the

hammer. And, in addition, corrosion, lack of lubrication or penetration of

could result in further damage to components of the hammer and

the carrier.

To operate the hammer under water, compressed air must be supplied

into the hammer, into the impact chamber of the front-head, prior to use.

Refer to the manual of underwater kit, which is a separate document,

provided with the underwater kit.

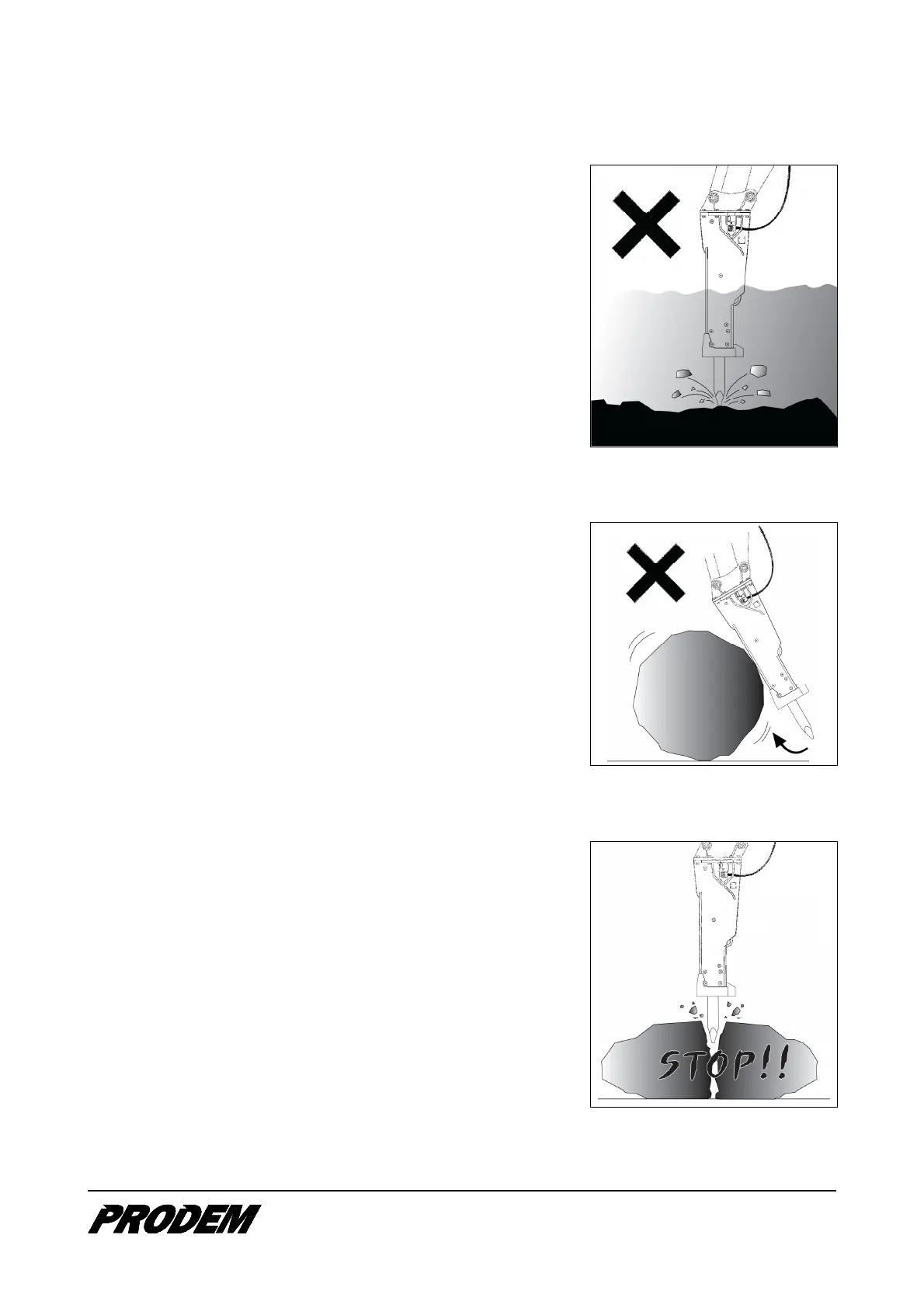

Never use the chisel or hydraulic hammer

to move rocks or other objects:

The hydraulic hammer is not designed for this usage.

Do not use the hammer or chisel to roll, push the object or reposition the

carrier.

This may cause damage to the hammer and the carrier.

Blank blows:

Blank blows, which are impact on the chisel without contact with the

object, are very harmful for the hammer. Always press the chisel down

onto the material before starting the hammer. And stop operation

immediately as soon as the object has been broken. If operation is

continued, blank blows could result in excessive wear to major

components.

Recent PRB200 and bigger hammers have a Anti-Blank-

prevent blank blowing.

Consult PRODEM dealer for the operating the hammer in special applications such as:

operation under water, operation in very high or low temperature, operation in chemical factory, etc.

Loading...

Loading...