- 42 -

Chisel pins:

Check the chisel pins for wear, every 50 hours of hydraulic hammer use or weekly as well as each time the

chisel is replaced. Any burr and swelling on the chisel pins must be smoothed off carefully by grinding.

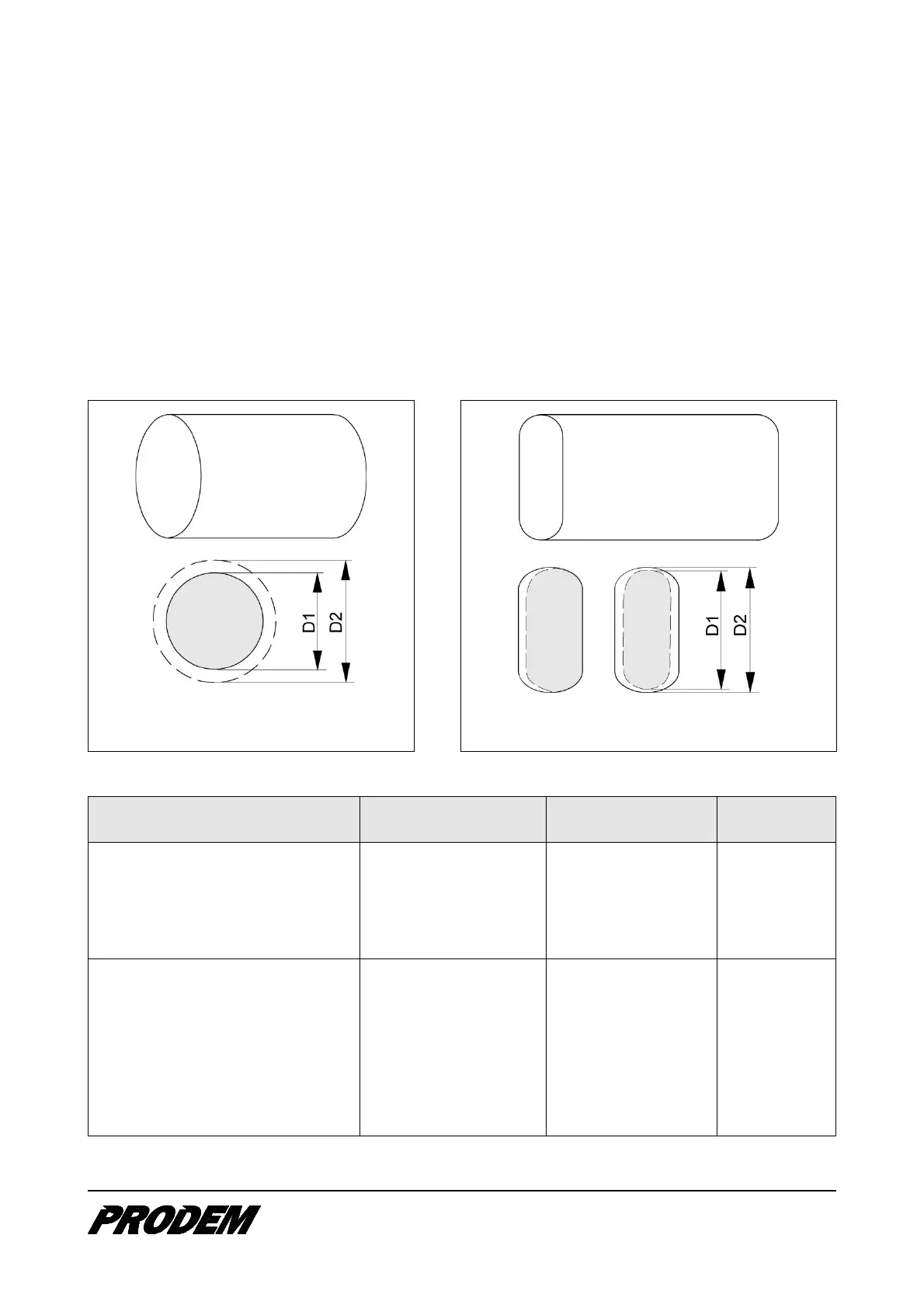

Circular type chisel pins (PRB008 ~ PRB100):

The initial diameters (D1) of the chisel pins are shown in the following table. Replace the chisel pin, if the

diameter is less than the lower limit (D2) of the diameter.

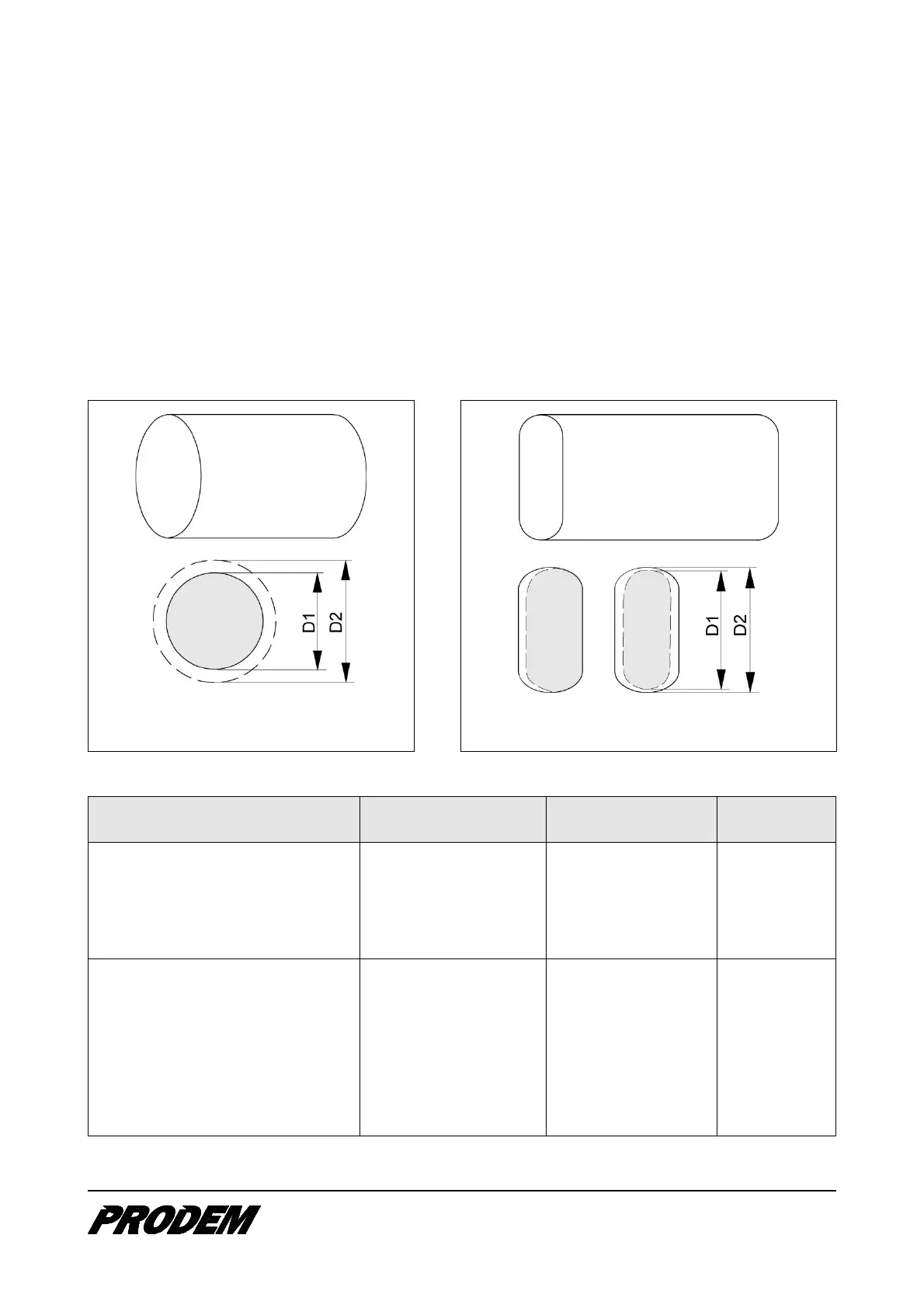

Plate type chisel pins (PRB150 ~ PRB700):

Check the width of the chisel pins including the worn out portion.

If the wear on the first side exceeds 1.5 mm, both chisel pins must be inverted together to use the other side.

Replace the chisel pins, if the final widths are less than lower limits (D2) of the width.

Circular type chisel pin

PRB008 ~ PRB100

Plate type chisel pin

PRB150 ~ PRB700

Dimension limits of Chisel Pins:

Unit: mm

Hammer Model

Original Dimensions

(D1)

Lower Limits

(D2)

Pin shape

PRB008 / 010 / 020 / 030 / 040(H) 25 23

Circular

PRB050 30 28

PRB060 33 / 38 31 / 36

PRB100 34 32

PRB150 69 65

Plate

PRB170 / 200 / 250 90 85

PRB300 89 85

PRB400 98 / 108 93 / 103

PRB500 108 / 118 103 / 113

PRB700 130 125

Loading...

Loading...