7 Repairs

Carry out repairs, which should be performed

by qualified technical personnel, in line with the

safety notes:

n Cleaning a valve

n Replacing the diaphragm

All other repairs: Contact your responsible

ProMinent branch!

Replacing the diaphragm

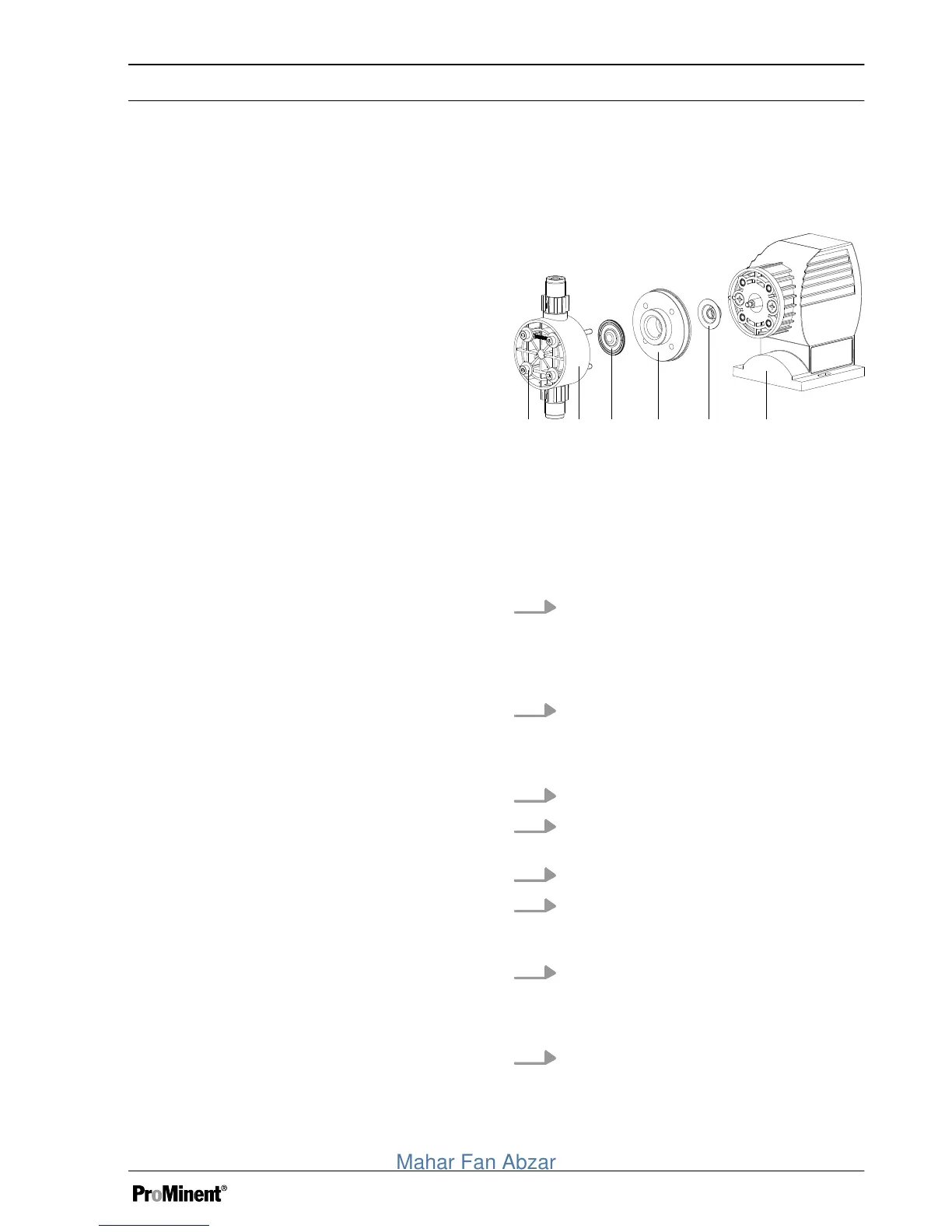

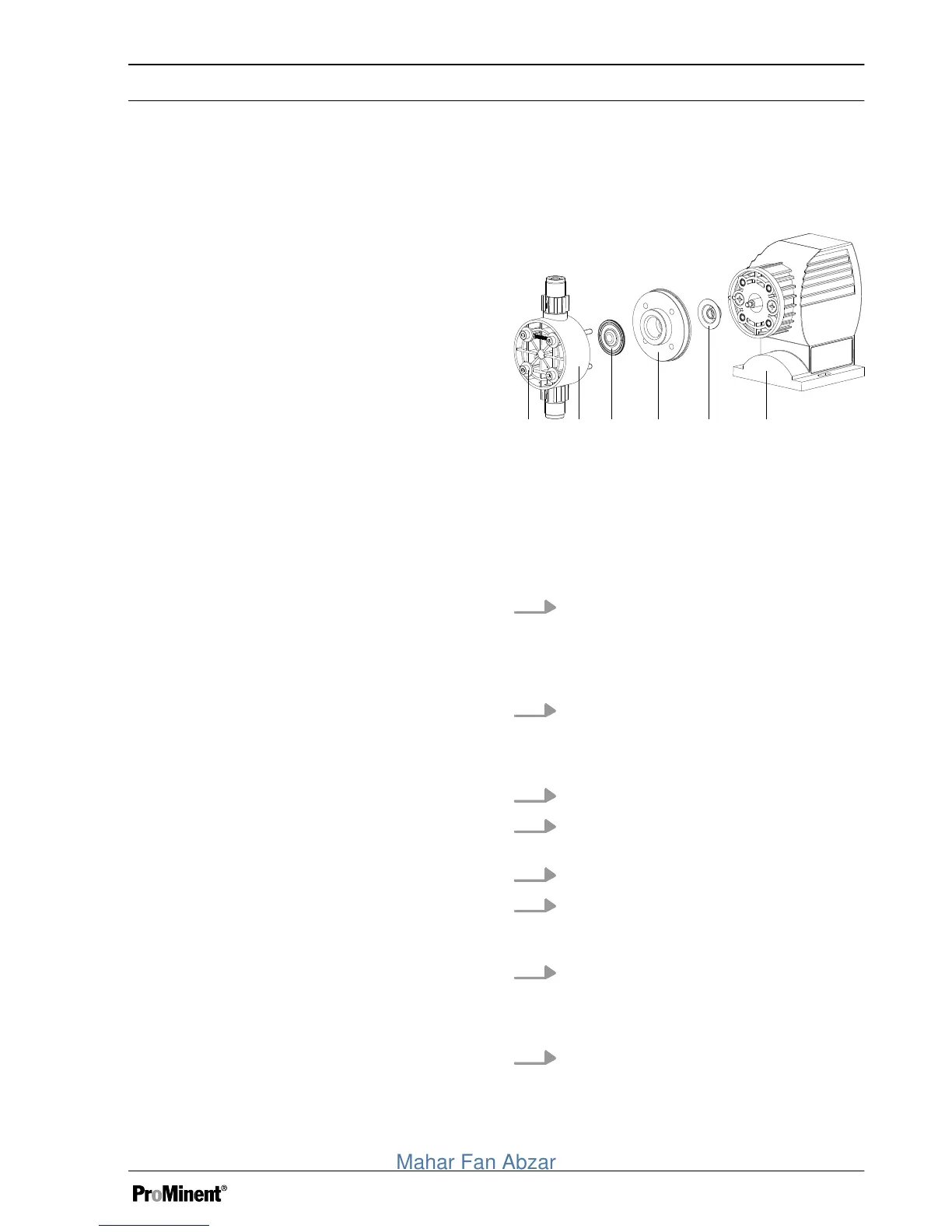

Fig. 4

n If necessary take protective measures.

n Adhere to the safety data sheet for the

feed chemical.

n Ensure that the system is at atmospheric

pressure.

1. Empty the liquid end (turn the liquid end

upside down and allow the feed chem‐

ical to run out; flush out with a suitable

medium; flush the liquid end thoroughly

when using hazardous feed chemicals!)

2. Turn the stroke adjustment dial as far as

0 % stroke length when the pump is run‐

ning (the drive axle is then difficult to

turn).

3. Switch off the pump.

4. Unscrew the hydraulic connectors on

the discharge and suction side.

5. Remove the screws (1).

6. Loosen the dosing head (2) and the

backplate (4) from the pump housing (6)

- but only loosen!

7. Hold the pump housing (6) with one

hand and clamp the diaphragm (3) with

the other hand between the dosing head

(2) and the backplate (4).

8. Loosen the diaphragm (3) from the drive

axle with a gentle backwards turn of the

dosing head (2), diaphragm (3) and

backplate (4) in an anticlockwise direc‐

tion.

Repairs

15

Mahar Fan Abzar

Loading...

Loading...