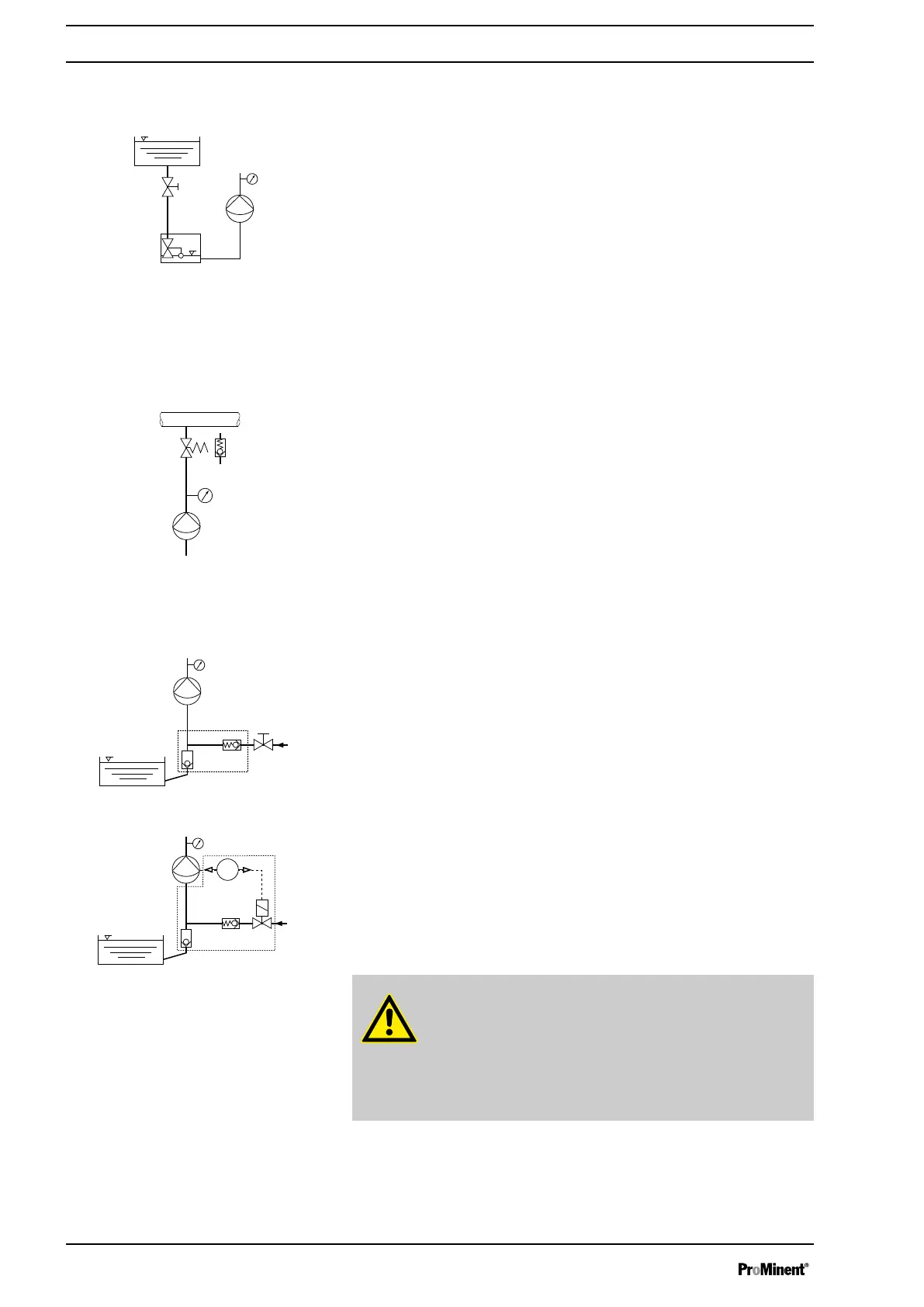

n If the system is primed from a high feed level with fluctuating pressure,

use a hopper with a float valve to ensure a regular discharge flow.

n When metering into a main line, in which there is negative pressure,

install a multifunctional valve, a back pressure valve (DHV-RM) or an

injection valve in the discharge line to ensure that the feed chemical is

not sucked through.

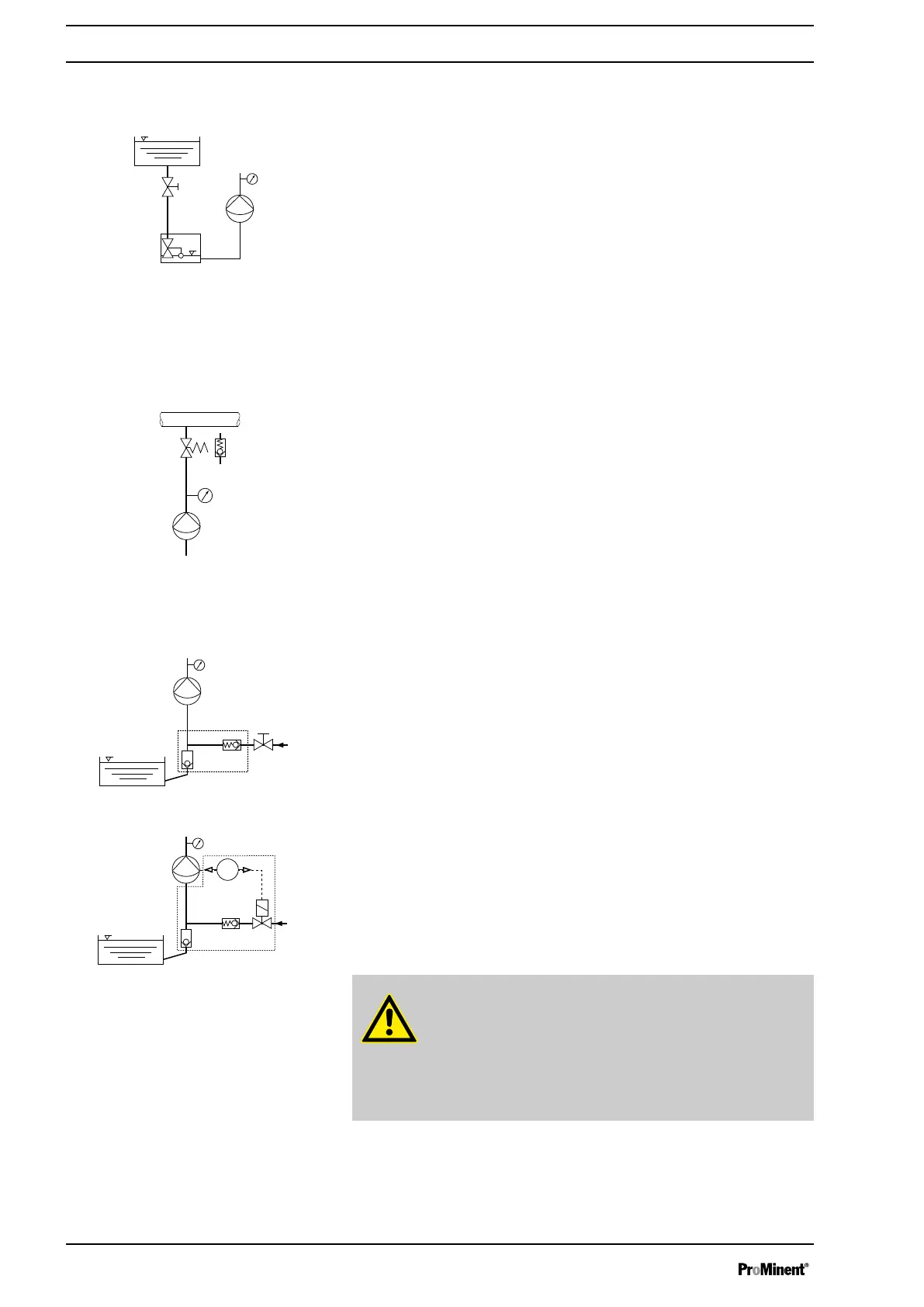

n When metering suspensions, use flushing equipment (see Product

Catalogue Chapter 1.8) to prevent deposits in the liquid end.

1 Rinsing water

2 Flushing equipment

There are two versions of flushing equipment:

n Manual flushing equipment

n Automatic flushing equipment

There are two flushing principles:

n Flushing when metering is interrupted (intermittent flushing)

n Flushing when metering is finished.

CAUTION!

Problems may arise if flushing cannot be performed cor‐

rectly.

– Ensure that the metering pump is idle during flushing.

– Do not exceed the maximum permitted flushing pressure

of 2 bar!

With fluctuating suction-side pressure 2

Fig. 24

With negative pressure in the main line

Fig. 25

With danger of deposits in the liquid end

Fig. 26: Manual flushing equipment

Fig. 27: Automatic flushing equipment

Installation, hydraulic

16

Loading...

Loading...