3.4

Information on the discharge-side installation

n Install a vacuum breaker if the feed chemical may not press through

the metering pump. A metering pump is not an absolutely leak-tight

shut-off device.

n Install the injection valve at the injection point to prevent unwanted

mixing of water and feed chemical in the discharge line.

n A relief valve with a return into the storage tank is useful as overload

protection for the discharge line, for example install a ProMinent

®

mul‐

tifunctional valve.

n Dampen pressure peaks with a metering stroke with long discharge

lines with a pulsation dampener or increase the pipe cross-section.

* Ventilation line with pressure vessels

PD Pulsation damper

n Dampen the pulsations with a pulsation dampener in order to avoid

metering errors, premature wear and tear and damage to the metering

system.

* Ventilation line with pressure vessels

PD Pulsation damper

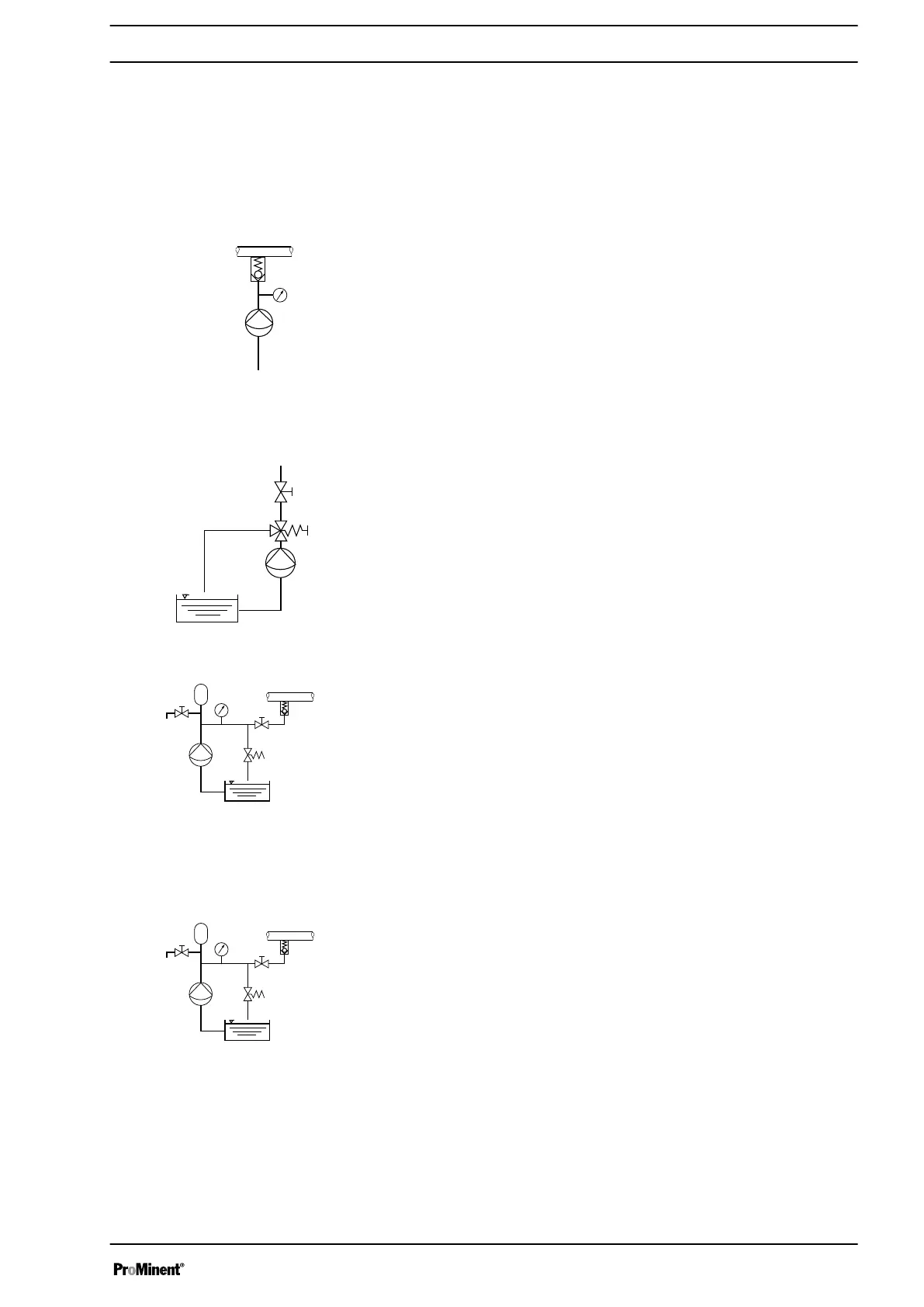

Fig. 11

With return from the main line

Fig. 12

Avoid exceeding maximum permissible

operating pressure

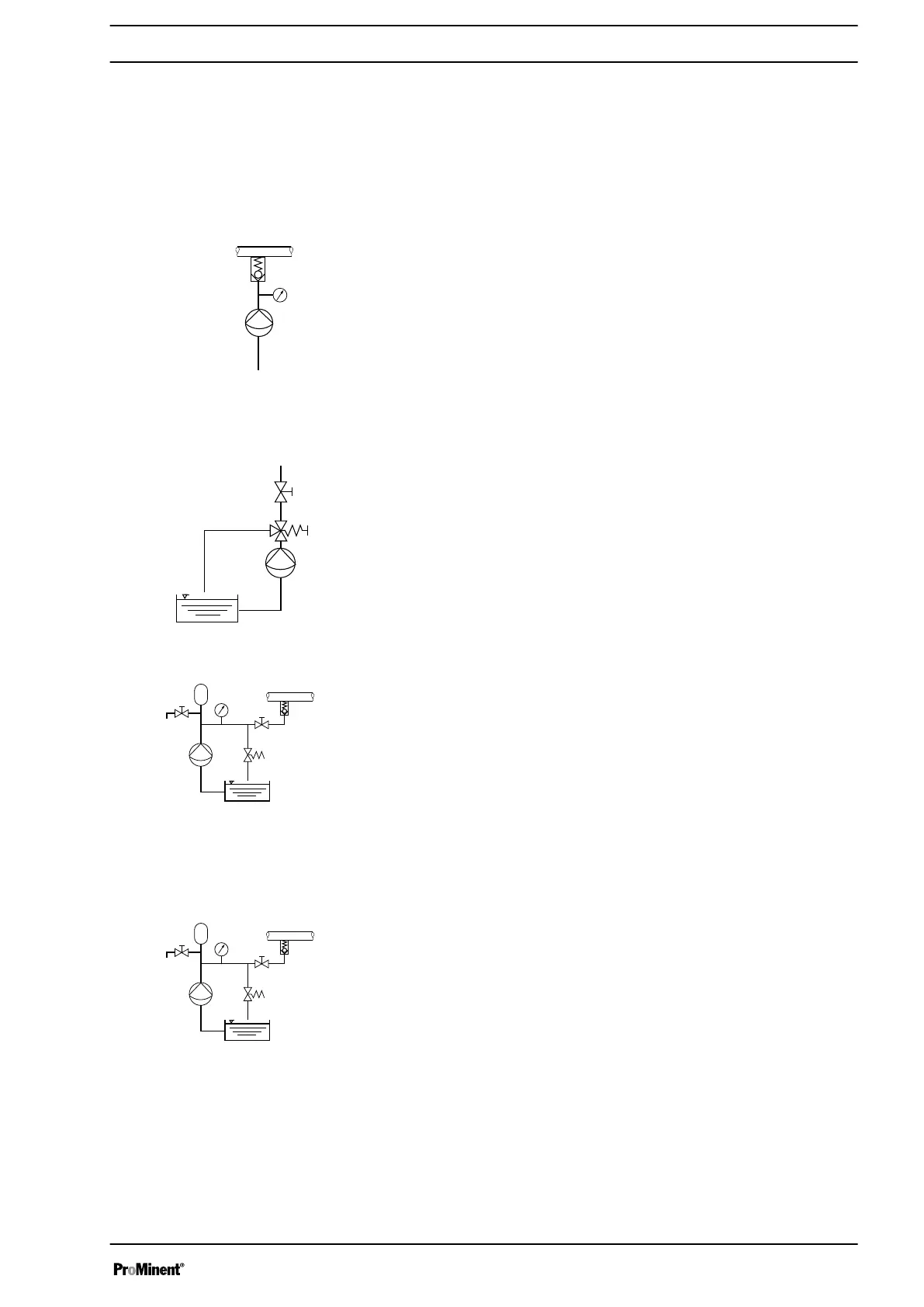

Fig. 13

Fig. 14

With pulsations caused by acceleration

inertial forces

Fig. 15

Installation, hydraulic

13

Loading...

Loading...