n fit a filter insert (mesh width 100–400 μm depending on the feed

chemical and type of metering pump) for example.

n Always connect the suction line somewhat above the tank base or any

sediment accumulated.

n With feed chemicals containing impurities or sediment, suspend the

foot valve at a sufficient distance above the tank base or any sediment

that has accumulated - see Fig. 6.

n Preferably route the suction line with a falling rather than a rising gra‐

dient to prevent the priming of air bubbles.

n Install the pump with the feed on the suction side.

n Install a foot valve at the end of the suction line, in case the pump is

higher than the maximum fluid level in the storage tank.

n Only shorten the free end of the suction line until the foot valve is sus‐

pended just above the container base.

n With high storage tanks without a connecting option at the tank base,

prime using a siphon line.

Install a filling device (

Fig. 10) or siphon vessel (Fig. 11) for the siphon

line (suction line).

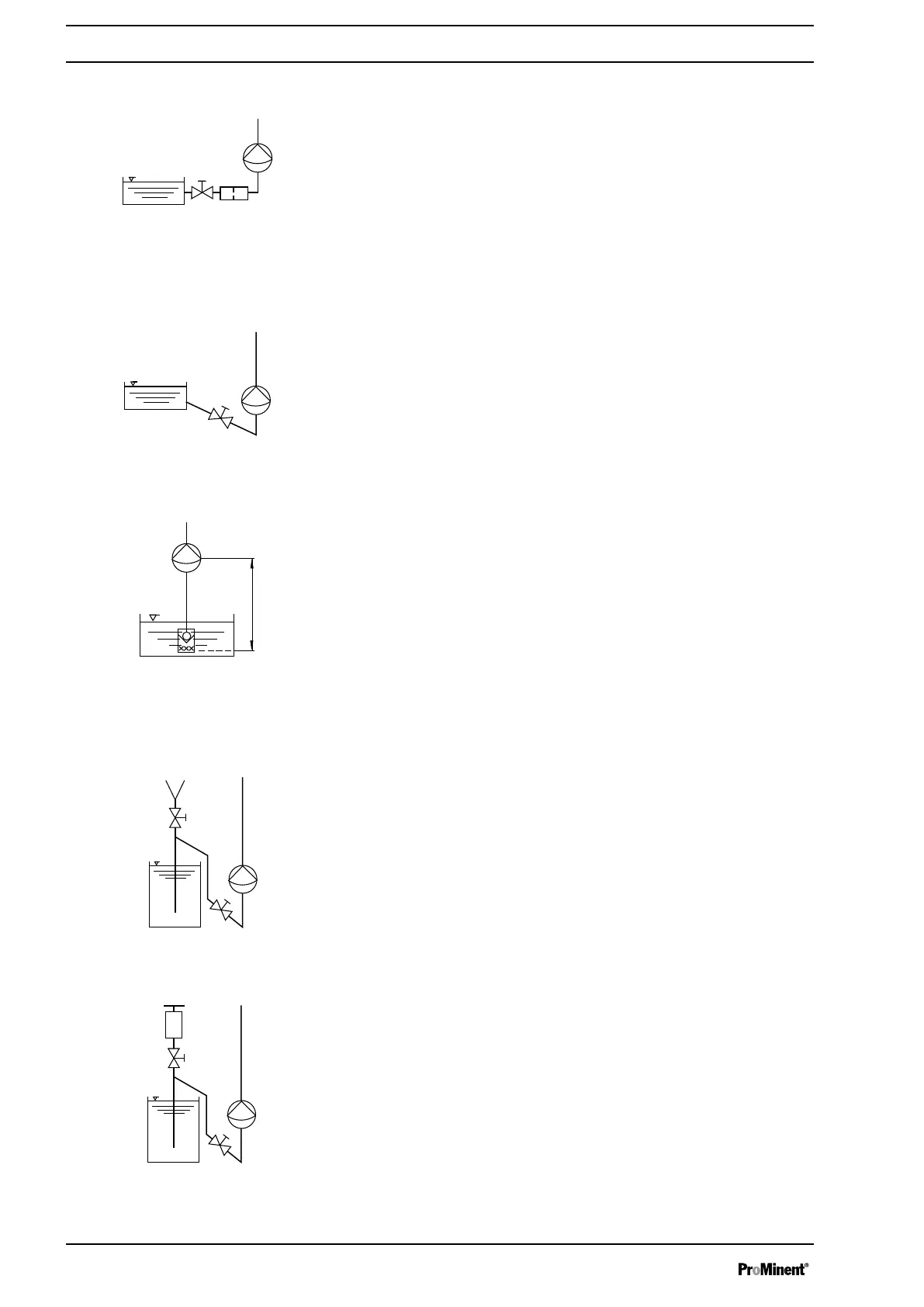

With dirt or impurities in the feed chemical,

Fig. 7

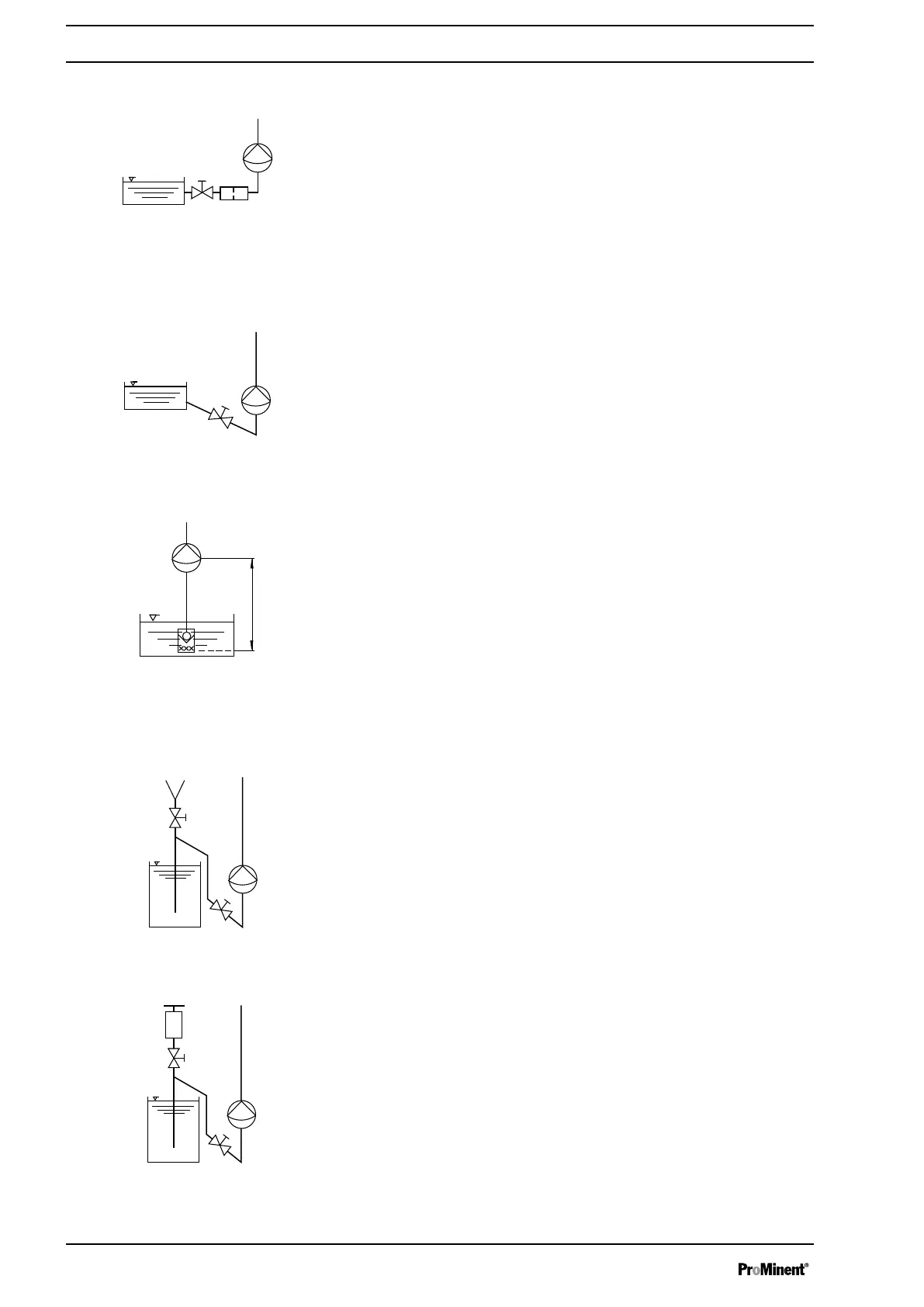

With slightly gaseous feed chemicals

(hydrogen peroxide, sodium-calcium hypo‐

chlorite ...)

Fig. 8

Avoid allowing the suction line to run dry.

Fig. 9

Prime without connecting options at the

tank base

Fig. 10

Installation, hydraulic

12

Loading...

Loading...