ProMinent

®

Page 11

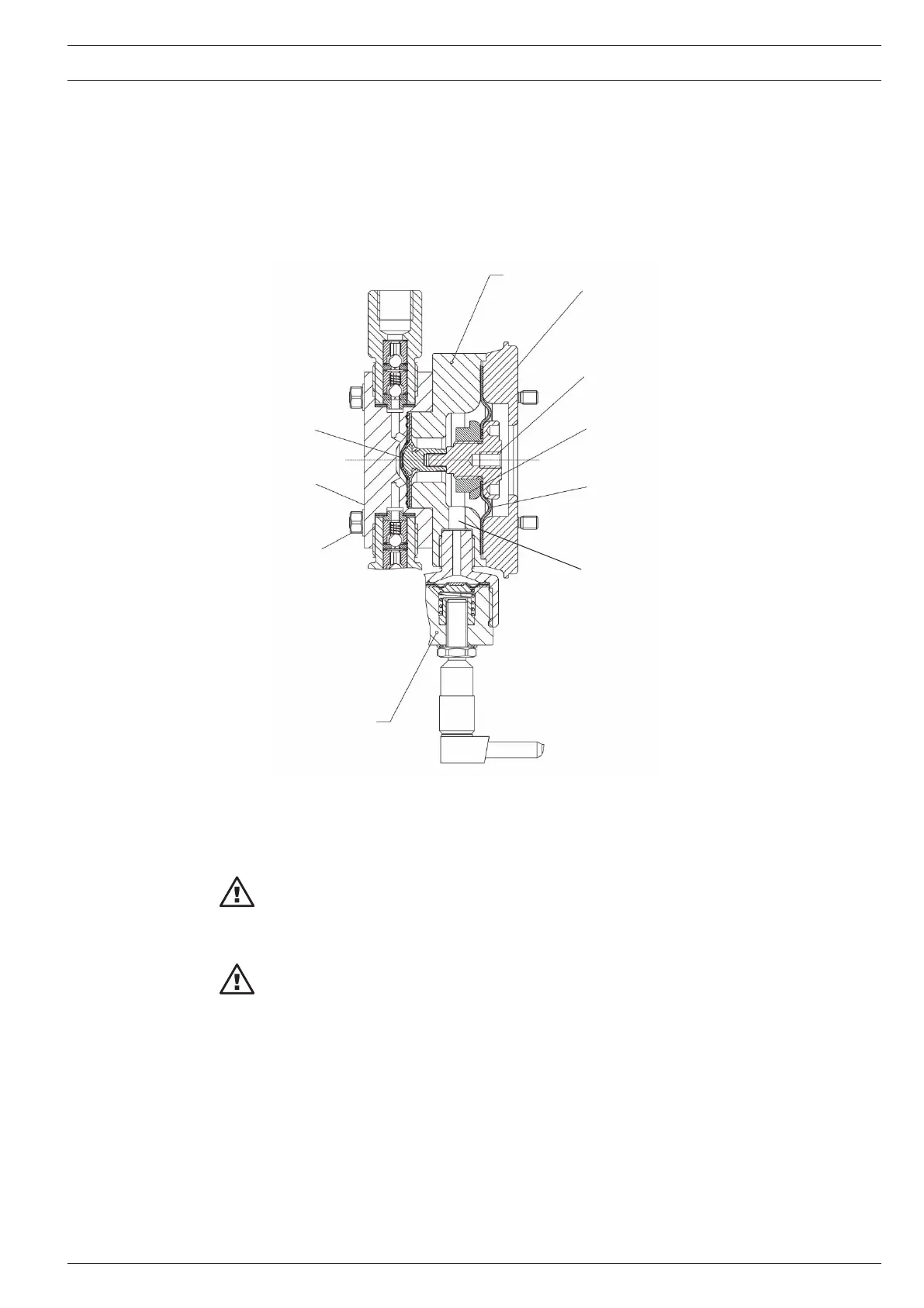

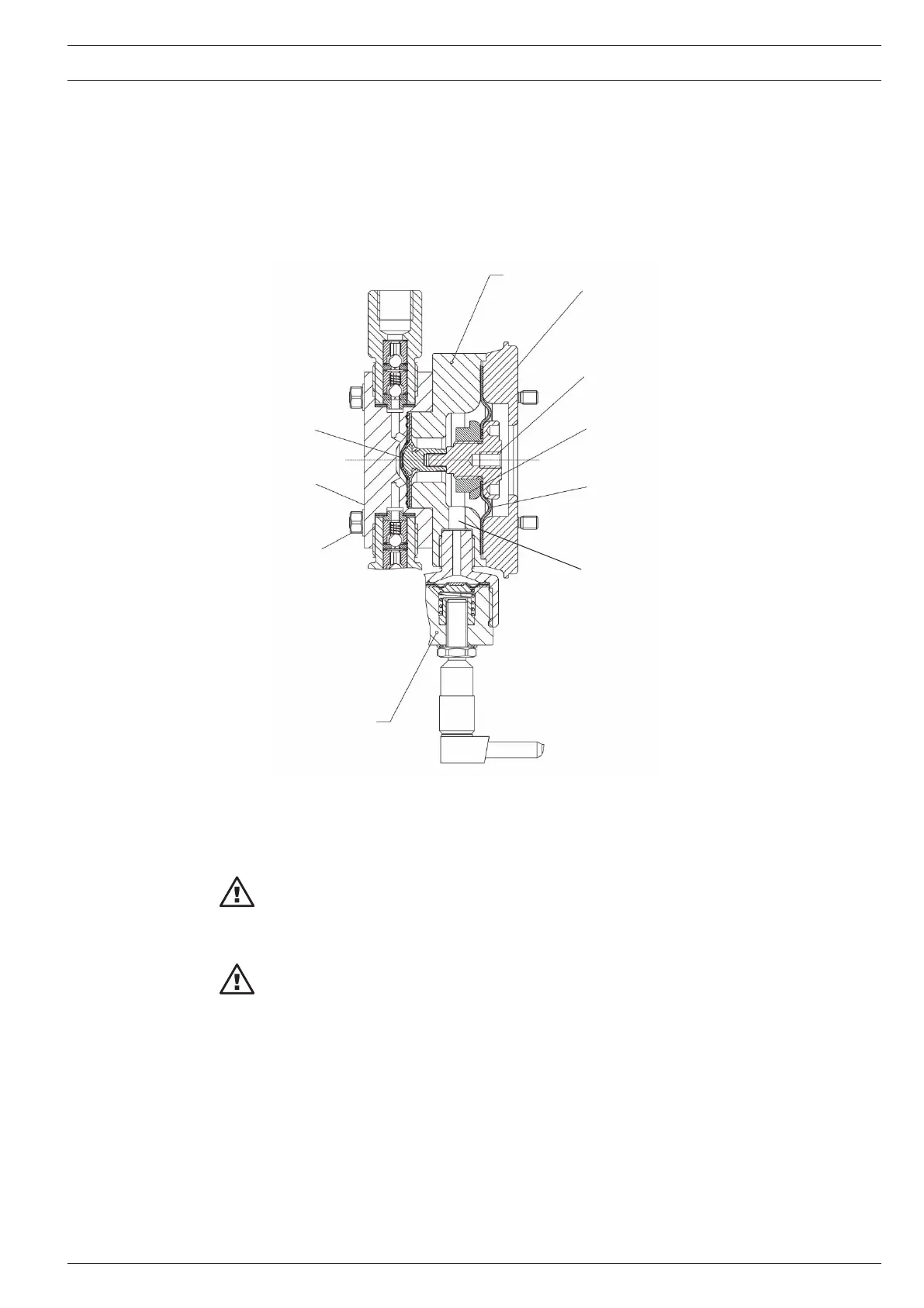

Design and Function

The safety diaphragm is situated between the top plate and the spacer plate and forms a sealed

interim chamber with the working diaphragm.

Function It serves to monitor ruptures in the working diaphragm and protects the power end from

corrosion and the environment from chemical leaks in the case of diaphragm rupture.

Even after diaphragm rupture, this liquid end can continue to operate in emergency mode at full

working pressure and without leaks until the diaphragm is changed.

fig.: 1

IMPORTANT

If the diaphragm ruptures, an electrical signal is triggered when the system back pressure

reaches approx. 2 bar.

IMPORTANT

Precise pump feed cannot be guaranteed after a working diaphragm rupture.

2.3 Feed rate

The delivery capacity is determined by the stroke length and the stroke frequency (rate).

The stroke length can be steplessly adjusted with the control knob for stroke length (14) during

operation from 100 % to 10 % and then locked. The maximum stroke length is 1.25 mm, 0.63

mm for type EXBb_1000.

A setting of 0 to 110 (120) stroke/min can be set manually with the control knob for stroke

frequency (rate) (16).

At a maximum stroke length and rate and a max. backpressure of 1.5 bar to 25 bar, the

diaphragm-operated metering pumps deliver at a rate of 0.2 l/h to 60 l/h.

1Top plate

2Adapter

3 Intermediate bush

4 Safety diaphragm

(Backup diaphragm)

5 Spacer

6Working diaphragm

7 Liquid end

8 Locking screw

9 Diaphragm rupture indicator

10 Intake line

1

5

2

3

4

10

9

8

7

6

BA_EX_014_01_12_EN.p65 31.10.2012, 7:32 Uhr11

Loading...

Loading...