ProMinent

®

Page 39

Repairs

fig.: 7

• Place the spacer plate (5) on the top plate

• Tighten new working diaphragm (6) with both hands until hand-tight.

• Further assembly instructions, see 8.2

8.2 Servicing diaphragm rupture detector

WARNING

• Disconnect the diaphragm rupture indicator from the monitor!

•Protect yourself from unknown or hazardous metering chemicals.

• After a diaphragm rupture there will be chemical in the diaphragm rupture detector and

the intake channel in the spacer plate (5).

• Check the diaphragm rupture detector after every diaphragm rupture and replace the

separating diaphragm if necessary (e.g. if the chemical is crystallising or is carrying

dirt and particles).

NOTE

• When screwing the diaphragm rupture indicator in or out, ensure that the cable does

not become too twisted.

• Connect the monitor to check for electrical continuity.

8.3 Checking the diaphragm rupture sensor

NOTE

• When screwing the diaphragm rupture indicator in or out, ensure that the cable does

not become too twisted.

• Connect the monitor to check for electrical continuity.

왘

When changing the diaphragm, unscrew the diaphragm rupture sensor from the dosing head.

왘 Check that the monitor does not indicate a diaphragm rupture:

왘 Using a blunt insulating probe (Ø 2 ... 3 mm, no sharp edges), press into the channel of the

diaphragm rupture sensor.

왘 The monitor must indicate a diaphragm rupture.

왘 Release the pin again.

왘 The monitor must no longer indicate a diaphragm rupture.

왘 Repeat the test several times.

왘 If everything is working correctly, screw the diaphragm rupture sensor into the dosing head

with a new seal (1).

왘 If not, go to the next section.

8.4 Replacing the separating diaphragm of the diaphragm rupture sensor

왘 Disconnect the diaphragm rupture sensor from the monitor.

왘

When changing the diaphragm, unscrew the diaphragm rupture sensor from the dosing head

.

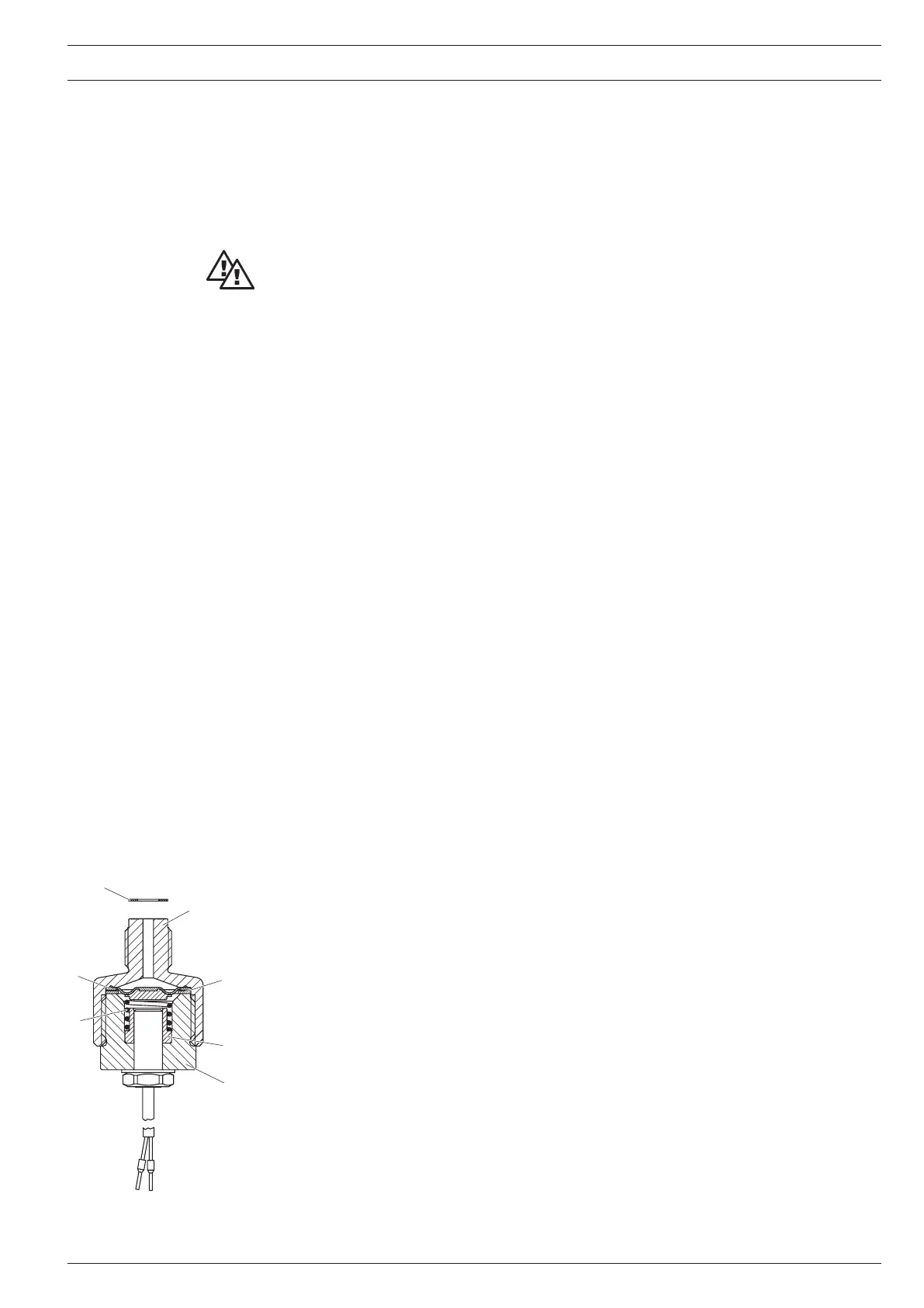

왘 Grasp the top part (2) of the diaphragm rupture sensor.

NOTE

• Do not tamper with the lacquer-protected nut.

왘 Hold the body (5) in place with an open-ended spanner.

왘 Unscrew the diaphragm rupture sensor.

왘 Clean the soiled parts.

왘 Lay the new separating diaphragm (3) with the light side (PTFE) down in the top part (2).

왘 Place the disc (4) in the top part (2).

왘 Place the spring inside the body (5).

왘 Move the body (5) close to the top part (2).

왘 The spring (6) must sit correctly on the spring seat (3a).

왘 Screw the body (5) in the top part and screw tight.

왘 Re-connect the diaphragm rupture sensor to the monitor.

왘 Check the diaphragm rupture sensor as described under “Check diaphragm rupture sensor”.

왘 If the diaphragm rupture sensor does not operate clearly and reliably, then a new diaphragm

rupture sensor must be used without fail.

BA_EX_014_01_12_EN.p65 31.10.2012, 7:32 Uhr39

Loading...

Loading...