When using abrasive feed chemicals, the diaphragm service life is

reduced. In such cases, more frequent checking of the diaphragm is rec‐

ommended.

Data Value Unit

Tightening torques for dosing head

screws:

4.5 ... 5.0 Nm

WARNING!

Warning of eye injuries

When opening the relief valve, a spring under high tension

can jump out.

– Wear protective glasses.

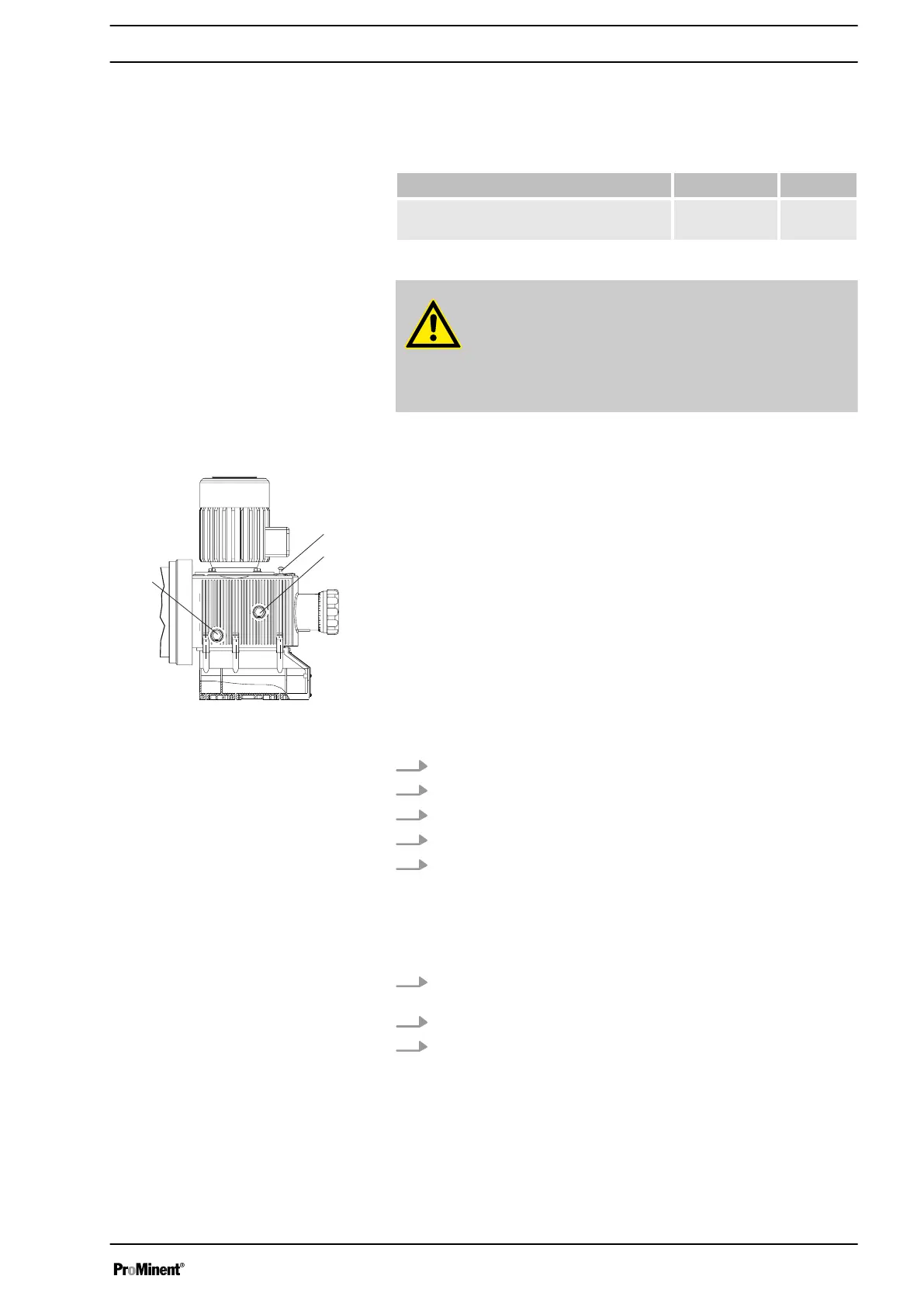

Draining gear oil

1. Remove the vent screw (1).

2. Place an oil trough under the oil drain plug (2).

3. Unscrew the oil drain plug (2) from the power end housing.

4. Allow the gear oil to run out of the power end.

5. Screw in the oil drain plug (2) with a new seal.

Filling with gear oil

Prerequisites: Gear oil according to the "Ordering information" chapter is

available.

1. Slowly pour gear oil through the vent screw (1) opening until the oil

inspection window (3) is half covered.

2. Allow the pump to run for 1... 2 minutes

3. Replace the vent screw (1).

Tightening torques

Liquid ends with integral relief valve

Changing gear oil

Fig. 20

Maintenance

33

Loading...

Loading...