ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

22

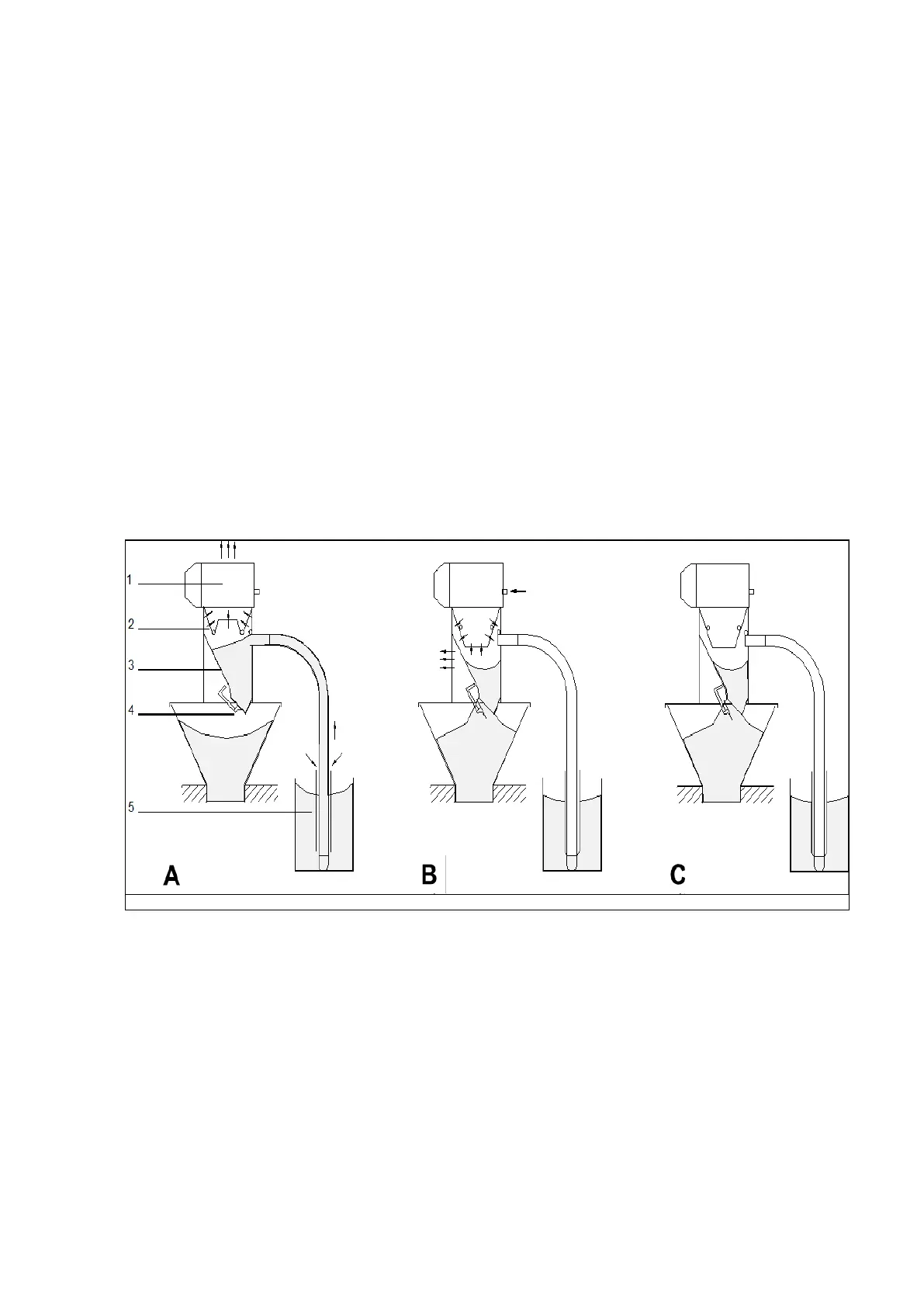

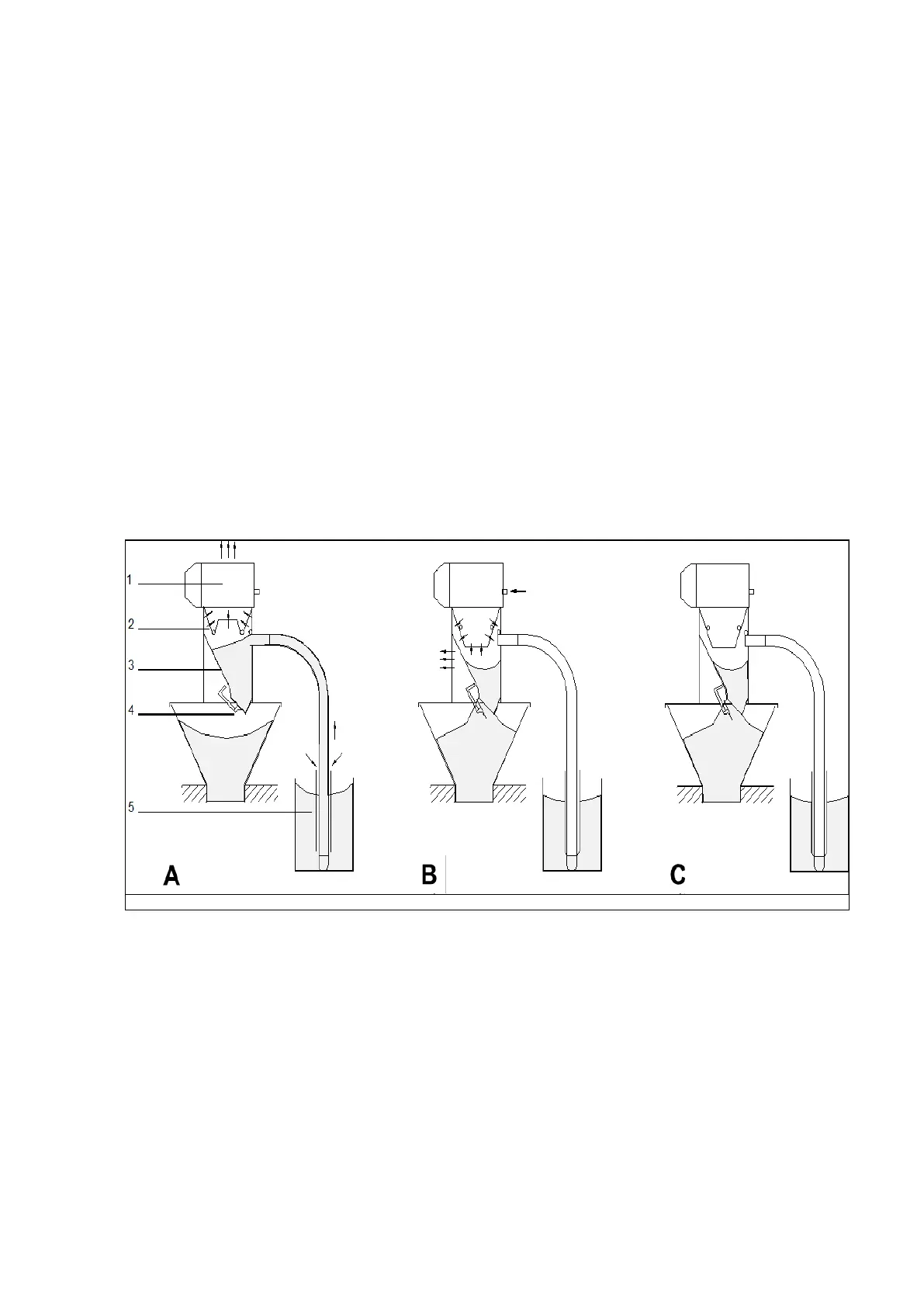

3.4.4 Function

The suction hose (5) is set in the material container and is used for suctioning the material to be

conveyed. A vacuum is generated in the conveyed goods container (3) with the blower (1) which

sucks up the material. The conveying air filter ensures the separation of the material from the

conveying air. For a unit with automatic cleaning the conveying air filter is cleaned with a shot of

compressed air.

After the conveying time elapses the blower shuts off. Through its own weight the material

presses on the discharge flap, opens it and flows out. When the conveyed goods container is

empty, the discharge flap closes automatically and a new conveying cycle begins. These

processes repeat as often as needed until the container under the conveyor is filled and the

discharge flap cannot close. Then there is a pause in conveying. If the material lowers so far that

the discharge flap closes again, a new conveying cycle begins.

3.4.5 Automatic cleaning of the conveying air filter

Cleaning is done in the home position before conveying. It can also be done before conveying or

before and after conveying.

1 Blowers

2 Conveying air filter

3 Conveyed goods container

4 Discharge flap

5 Suction hose

Loading...

Loading...