P2_GEPARD_installer manual_ work basis_EN_02 - 03/10 - protherm

- 14 -

INSTALATION

Regulations 7.1

The type MOV is designed for combustion gases to be removed

and discharged into a chimney (through a chimney inlet) with

a minimum stabilised thrust of 2 Pa. The boiler is connected to

the chimney inlet by a fl ue of a diameter corresponding to the

size of the boiler’s gas exhaust outlet. It is forbidden to place

inside the combustion gases exhaust ducting any objects which

impair the combustion gases fl ow (e.g. various types of heat

exchangers to utilise their residual heat). The combustion gases

exhaust ducting is not part of the boiler accessories.

Construction of the combustion gases exhaust ducting as well

as that of the chimney must comply with relevant requirements.

Compliance with the requirements specifi ed by these standards

will prevent undesirable phenomena from occurring, such as

excessive cooling of the combustion gases, penetration of

dampness into brickwork and fl uctuations in the chimney thrust,

and thus prevent undesirable effects on the boiler’s functioning.

The boiler takes combustion air from the space in which

it is installed. Air must be supplied in suffi cient quantity in

accordance with applicable regulations.

Venting of exhaust and drawing in of combustion air for the

MTV type is done only through designated pipes.

The level sections of the piping slope at a gradient suffi cient to

let the condensation drain towards an outside area or towards

a receptacle designed to draw off condensation. To achieve

this, the elbow joint may be gently bent away from the straight

section. The upright sections of the piping are always fi tted with

devices to draw off condensate. The devices for drawing off the

condensate are installed where possible close to the passage

where the exhaust exits the boiler. Breakdowns caused by

leaking condensate are not covered by the boiler warranty.

Description exhausting kits7.2

Methods of air and fl ue gas ducting 7.2.1

(according to STN EN 483) and permitted

piping lengths

If not described otherwise for the individual following methods

of placing coaxial pipe routes and their drainages, the piping

lengths (from connection at the boiler to the drainage) can be

set as in the following cases.

Note: One Em is considered as either a 1 m direct section or

one 90° joint.

Caution: If the lengths described for individual types are

exceeded, the exhaust diffuser (orifi ce) must be removed from

the ventilator drain.

The following methods of air intake and exhaust venting are

recommended for the boiler:

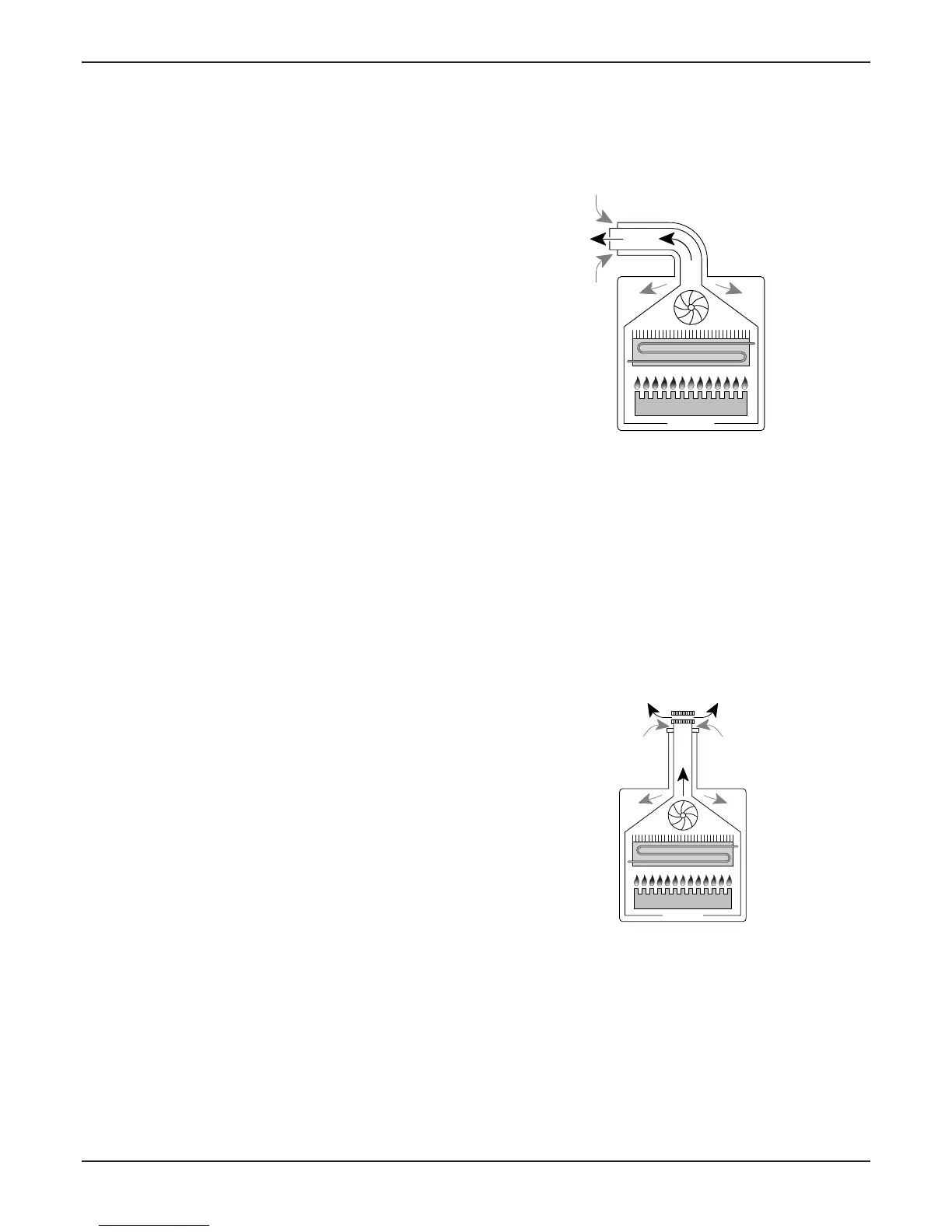

The C7.2.2

12

method (MTV)

Level routes and level venting into an open area.

Length of fume ducting (23 MTV):

60 / 100: min. 0.3 m (with one 90° joint), max. 3 m (with one -

90° joint).If the total fume ducting length is more than 0.5 m,

the diffuser with a diameter of 39 mm must be removed.

80 / 125: min. 0.5 m (with one 90° joint), max. 9 m (with one -

90° joint).If the total fume ducting length is more than 1 m,

the diffuser with a diameter of 39 mm must be removed.

An example of a level coaxial pipe route: version C

12

(complies

with STN EN 483)

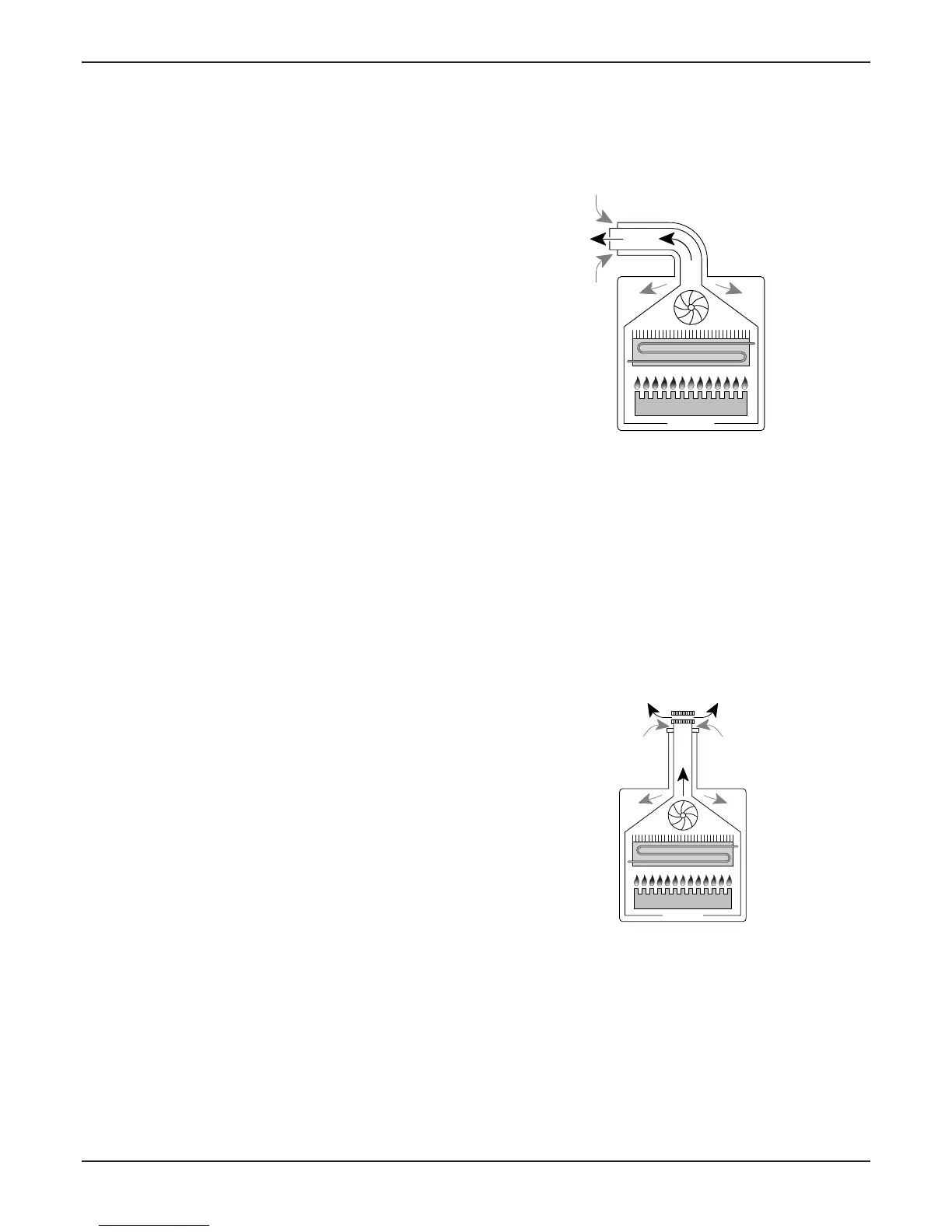

The C7.2.3

32

method (MTV)

Vertical routes and vertical venting into an open space.

Length of fume ducting (23 MTV):

60 / 100: min. 1 m (with one 90° joint), max. 4 m (with one -

90° joint). If the total fume ducting length is more than 1.5 m,

the diffuser with a diameter of 39 mm must be removed.

80 / 125: min. 1 m (with one 90° joint), max. 10 m (with one -

90° joint). If the total fume ducting length is more than 1.5 m,

the diffuser with a diameter of 39 mm must be removed.

An example of a vertical coaxial pipe route: version C

32

(complies with STN EN 483)

The C7.2.4

42

method (MTV)

Connecting to a double shared chimney.

Double piping from independent boilers (independent routes)

can feed into shared chimneys; the transport capacity of the

chimney is judged according to the manufacturer’s data on the

chimney. If the pipes are set into the chimney in two directions

and vertically aligned, there must be a vertical separation

between the outlets of at least 0.45 m. Where two outlets vent

towards each other, they must be separated by a minimum

vertical distance of 0.6 m. The exhaust piping into the shared

Loading...

Loading...