The function can be used to check the trail and code before you start the real cutting process, or can also be used when the process needs through the

gun. Press the red “STOP” key to stop the null cutting process if you want.

BACKWARD

During the running process, if you want to go backward

according to the origin trail to (maybe the iron board was

not cut through), you can follow the following direction:

• First, press “STOP” key to set the machine at pause status.

• In the automatic function interface, press key [F3] (Back)

to make the machine go backward along with the original

trail. When the torch reaches the position you need, press

“STOP” key to stop it. You may press key [F2] to go forward

if the machine just went back too much.

Notice: Go backward or forward function can be used

repeatedly to make the machine reach an ideal position.

• When the torch reaches the position you need, press

“START” key again, if the current cutting code is G01, G02

or G03, system will automatically perforate before

performing these procedures, and then continue the

current program, if the current row is not G01, G02 or

G03, the system will directly continue the current line

program.

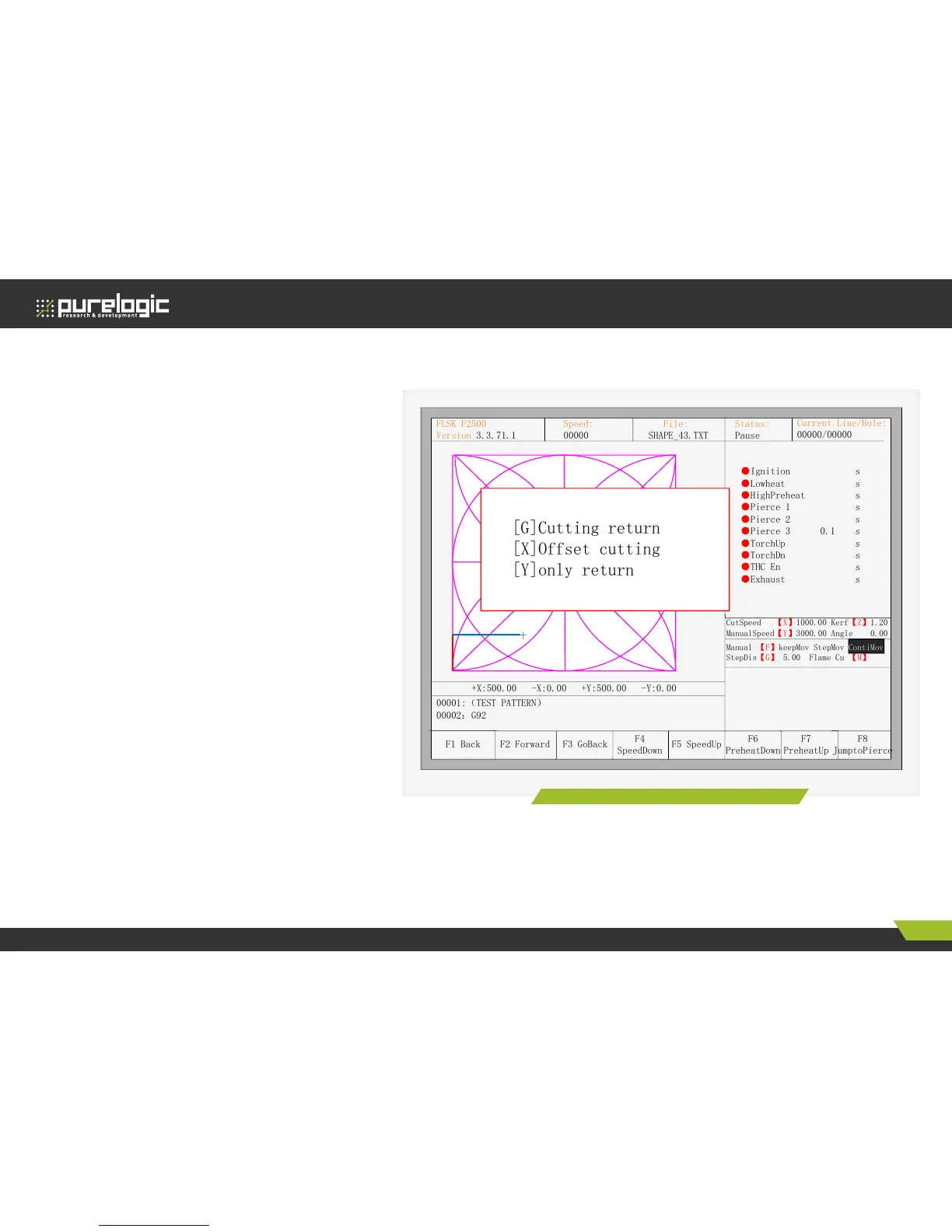

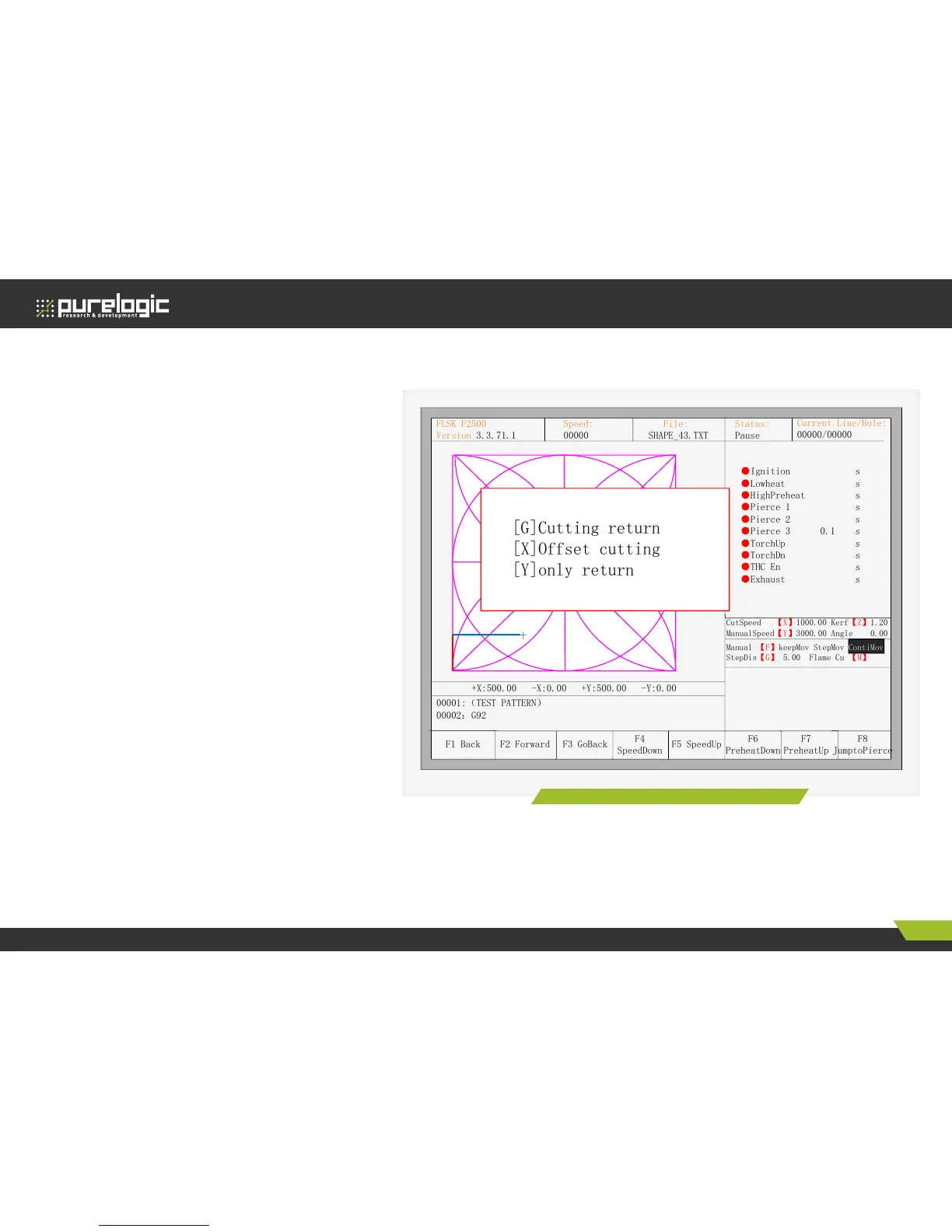

EDGE CUTTING / OFFSET CUTTING / RETURN

When the torch is not on the actual path of the

current work piece, it will prompt as follows.

There are two reasons led to this situation:

1) When the common parameter «edge perforation»

selects «Yes» and the next processing line G-code is M07,

the system will be automatically suspended. At this time, the torch can be manually moved to any edge of the plate, press the «start» button, the system

will prompt as above.

2) When the processing is paused, due to mechanical failure or other reasons, it needs to move the torch out of the actual path of the workpiece, the

above prompt will appear. move the torch out of the actual path of the workpiece, the above prompt will appear.

• If press [G], the system cutting returns back to the paused point, continue to cut it. This feature is particularly useful for thick steel plate, it can reduce

F1 Back F2 Forward F3 GoBack

F4

SpeedDown

F5 SpeedUp

F6

PreheatDown

F7

PreheatUp

F8

JumptoPierce

FLSK F2500

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Pause

Current Line/Hole:

00000/00000

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

00001:(TEST PATTERN)

00002:G92

●Ignition s

●Lowheat s

●HighPreheat s

●Pierce 1 s

●Pierce 2 s

●Pierce 3 0.1 s

●TorchUp s

●TorchDn s

●THC En s

●Exhaust s

Manual 【F】keepMov StepMov ContiMov

StepDis【G】 5.00 Flame Cu 【M】

CutSpeed 【X】1000.00 Kerf【Z】1.20

ManualSpeed【Y】3000.00 Angle 0.00

[G]Cutting return

[X]Offset cutting

[Y]only return

F1 Back F2 Forward F3 GoBack

F4

SpeedDown

F5 SpeedUp

F6

PreheatDown

F7

PreheatUp

F8

JumptoPierce

FLSK F2500

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Pause

Current Line/Hole:

00000/00000

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

00001:(TEST PATTERN)

00002:G92

●Ignition s

●Lowheat s

●HighPreheat s

●Pierce 1 s

●Pierce 2 s

●Pierce 3 0.1 s

●TorchUp s

●TorchDn s

●THC En s

●Exhaust s

Manual 【F】keepMov StepMov ContiMov

StepDis【G】 5.00 Flame Cu 【M】

CutSpeed 【X】1000.00 Kerf【Z】1.20

ManualSpeed【Y】3000.00 Angle 0.00

[G]Cutting return

[X]Offset cutting

[Y]only return

Loading...

Loading...