29

4

29

Figure 11

G

ATTENTION

All refrigerant work and refrigerant piping should comply with the local legislation, standards

and codes and should only be done by qualified and skilled people.

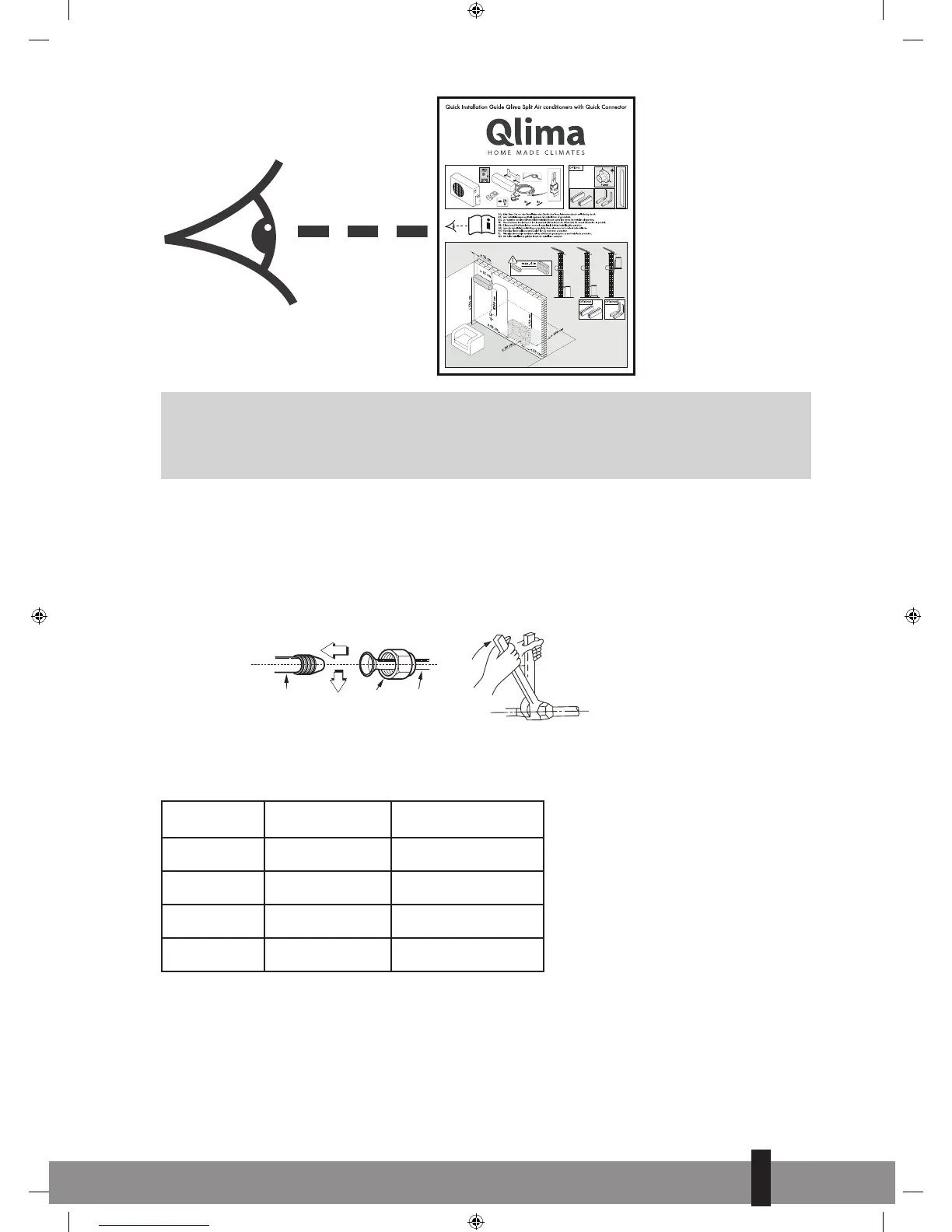

7.1 Connecting the coolant pipes for the S-JA2518 models

a. Fit a gland nut or suchlike to the piping and make a so-called “flare” at the end of the piping.

b. Interior unit: Tighten the gland nut by hand to the piping on the interior unit and then tighten it

with a spanner and torque wrench as shown in fig. 13.

c. Exterior unit: Tighten the gland nut by hand to the connections on the valves on the exterior unit

and then tighten it with a spanner and torque wrench as shown in fig. 13.

Indoor unit tubing

Flare nut

Pipings

Figure 13

d. Select the correct tightening torque (shown table 1) in order to prevent the pipes, connecting pieces

and nuts from being damaged.

Outer

diam.

Tightening torque

(N.cm)

Additional tightening

torque (N.cm)

Ø 6.35

1500

(153kgf.cm)

1600

(163kgf.cm)

Ø 9.53

2500

(255kgf.cm)

2600

(265kgf.cm)

Ø 12.7

3500

(357kgf.cm).

3600

(367kgf.cm)

Ø 16.0

4500

(459kgf.cm).

4700

(479kgf.cm)

e. Insulate the connection points on the interior section with insulation material to prevent condensa-

tion build-up .

f. Wind the piping, connection cable and drain hose, behind the interior unit, with tape so that a firm

bundle is formed. This makes it easier to mount the interior unit to the mounting plate.

Q_instal_S-JA2518 ('17) V2.indd 29 30-10-17 14:42

Loading...

Loading...