10 | Gas connection for gas units

80.06.070_iCombi Pro-iCombi Classic_IM_V01_en-GB 71 / 92

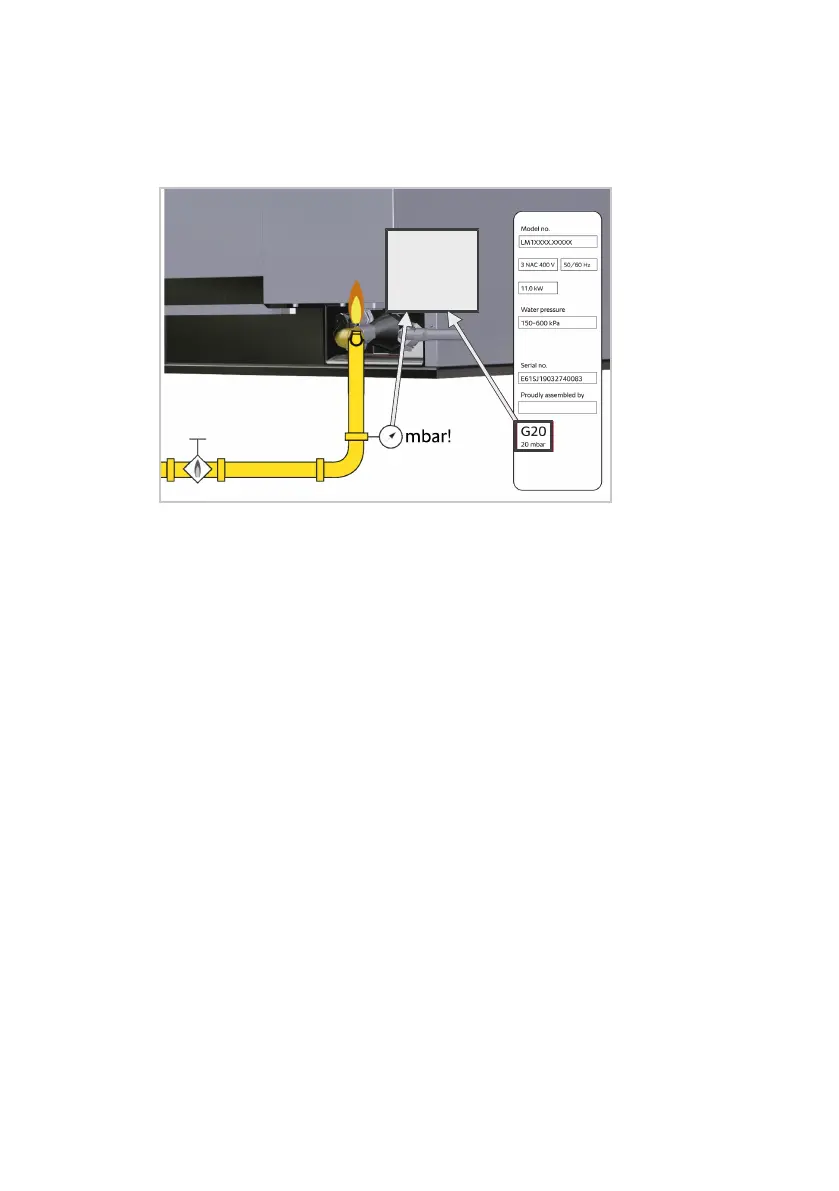

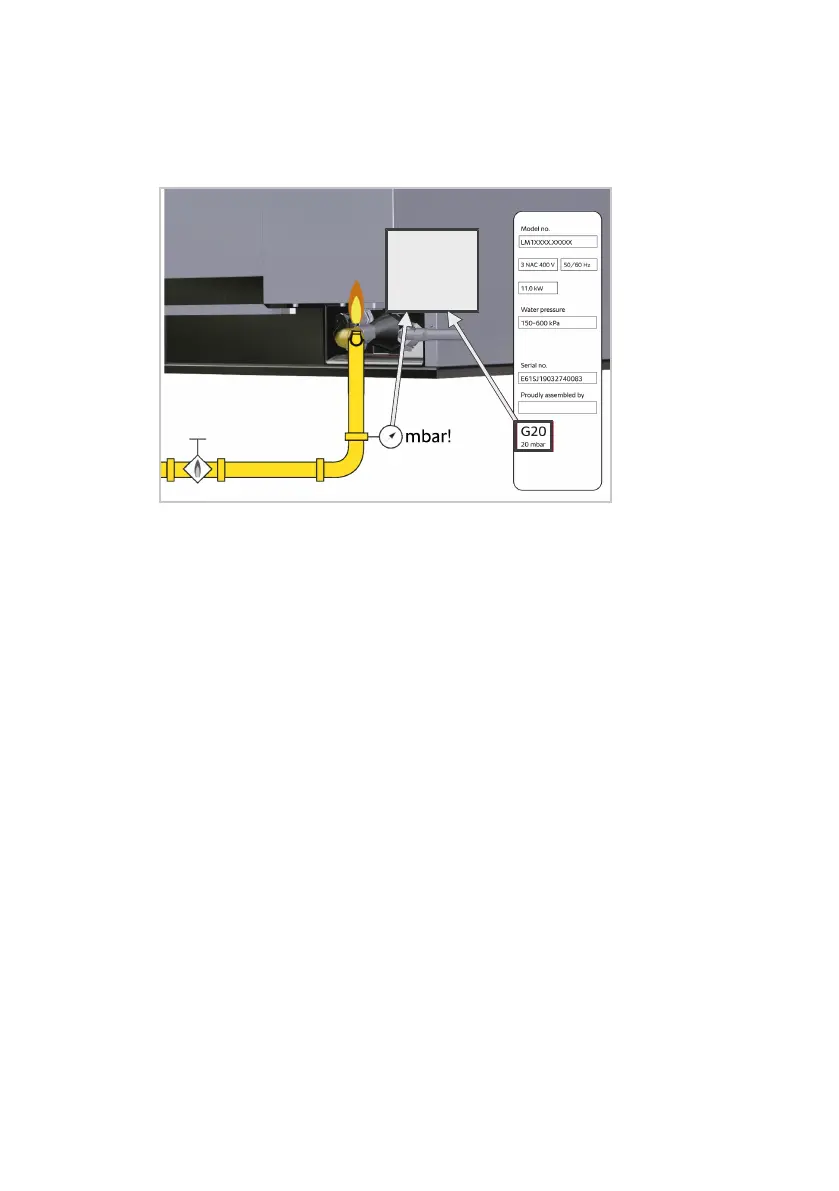

Requirements for gas type and gas pressure

n

Check that the factory gas setting on the unit corresponds to the actual local

gas supply conditions.

n

The gas type and the dynamic connection pressure set on the unit must cor-

respond to those stated on the type plate.

n

If the line pressure deviates from the connection flow pressure of the unit,

contact your gas supply company.

n

Adhere to all local gas company regulations.

Requirements for gas inlet and gas line

n

The exhaust gas analysis may only be carried out by a technician who is au-

thorised by the manufacturer. The exhaust gas analysis must be carried out

before commissioning.

n

Gas connections must only be set up by locally authorised gas technicians.

n

The gas connection line must be set up in accordance with the rated thermal

load specified on the type plate.

n

Use a suitable gas leak detector to check for leaks in the gas supply and gas

distribution within the unit.

n

The cross-section of the gas line must be designed to the maximum con-

nected output of all loads, at least ¾ inch.

n

A gas shut-off valve must be installed in front of every unit.

n

All connection components installed on-site must be checked in accordance

with DIN-DVGW (local gas supply company).

n

It is possible to connect the gas line with a gas socket.

n

A connection with an internal thread is necessary to connect the gas line.

n

The unit must be protected against slipping.

n

If undiluted CO levels are above 174.7 mg/m³ [150 ppm] for convection

mode and 465.8 mg/m³ [400 ppm] for steam mode, a company-trained

and certified technician must be called in to check burner settings in accord-

ance with setting instructions, and adjust these settings if needed. A flue gas

analysis must then be performed by the technician.

n

Follow the maintenance instructions for gas components.

n

The gas installation must meet the CGA-B 149.1 natural gas regulation or

the CGA-B 149.2 propane gas regulation.

Loading...

Loading...