Real Clean System I v 2.1

Real Tech Inc. 13

7 Cleaning

The Real Clean system comes with a 1L chemical storage bottle. After

a cleaning cycle, approximately 85% of the used cleaning fluid is

pumped back into the bottle reducing the need to replenish the fluid

on a regular basis.

Two important factors that affect the sensor performance are the

cleaning fluid used to clean the flow cell, and how often the flow cell

is cleaned (cleaning frequency).

Cleaning Frequency

The optimum frequency of cleaning is quite variable depending on

the amount and type of fouling agents in the water. This will be

dependent on the application and installation point.

For wastewater, a higher frequency will be required (ex. 1-24hrs)

whereas high purity water will require a lower frequency (ex. once a

month). Each installation will be different and require configuration

onsite.

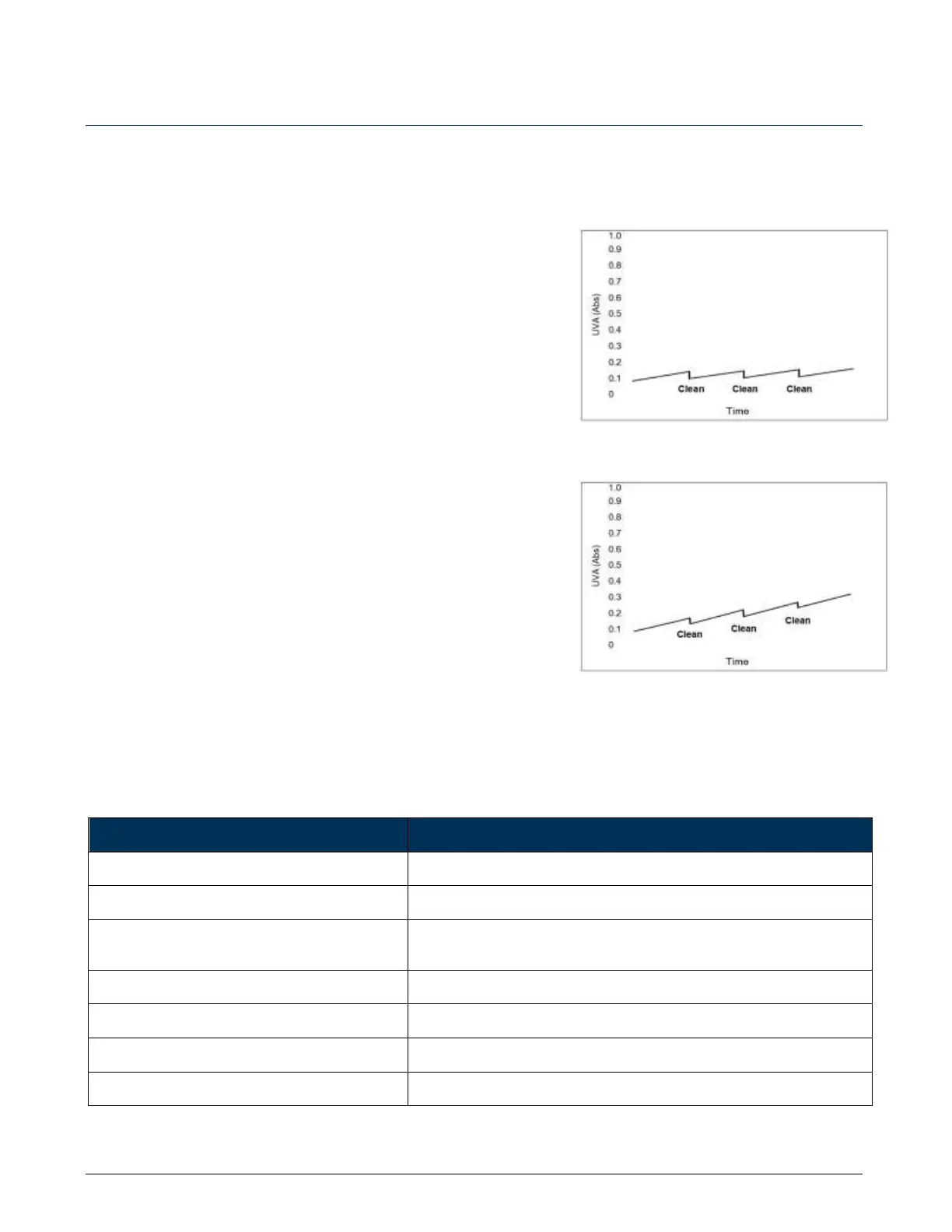

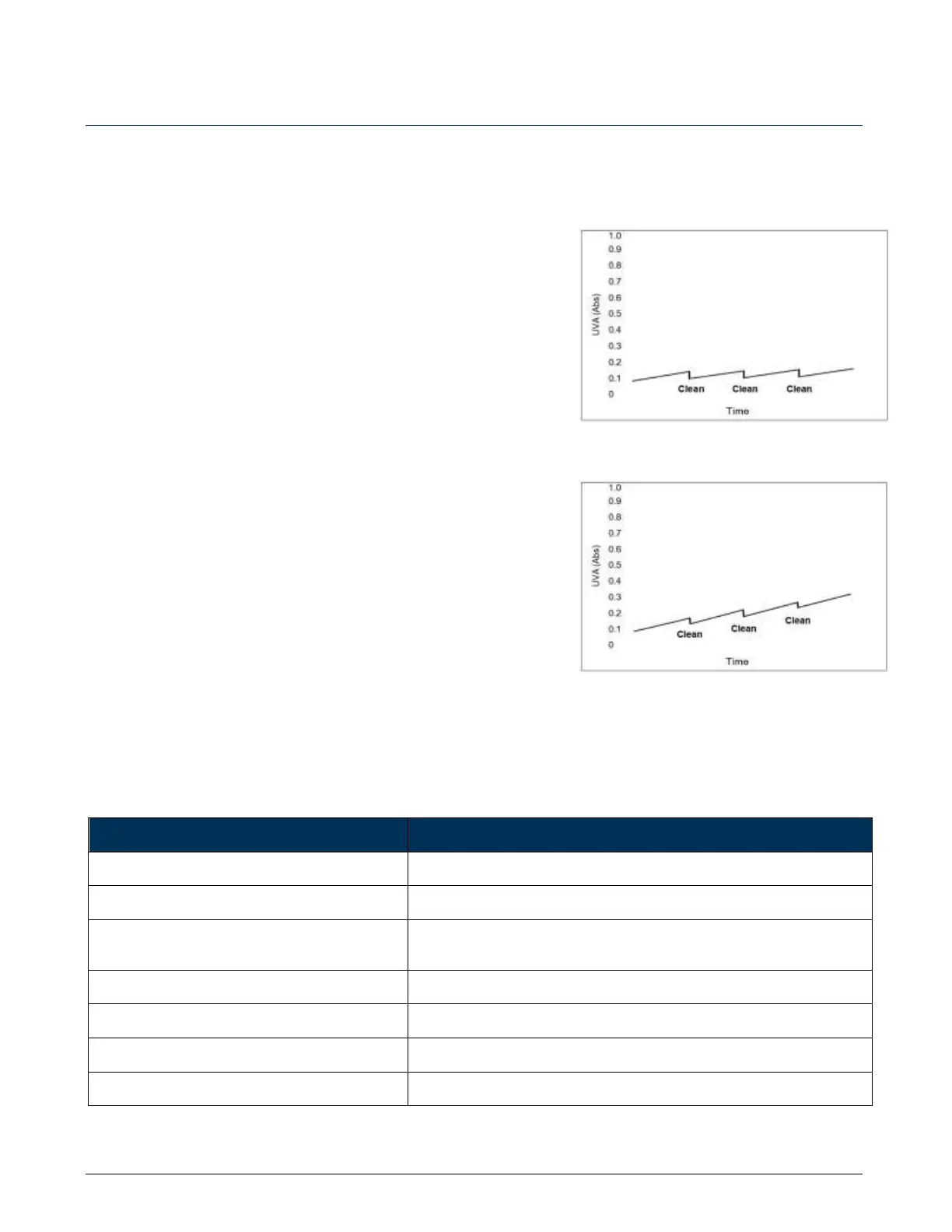

Once in operation, observe the flow cell for signs of fouling prior to

the first cleaning cycle. If fouling is present, increase the cleaning

frequency accordingly. The measured data can also be observed for

signs of a saw tooth effect as shown in Figure 7.1. If the saw tooth

shows an upward trend, as shown in Figure 7.2, the sensor is drifting

and cleaning frequency must be increased.

Cleaning Fluid

Selecting an effective cleaning solution is essential for optimal

performance. The following commercial cleaning solutions and acids

are readily available to remove common fouling agents.

Table 3: Commercial cleaning solutions

Loading...

Loading...