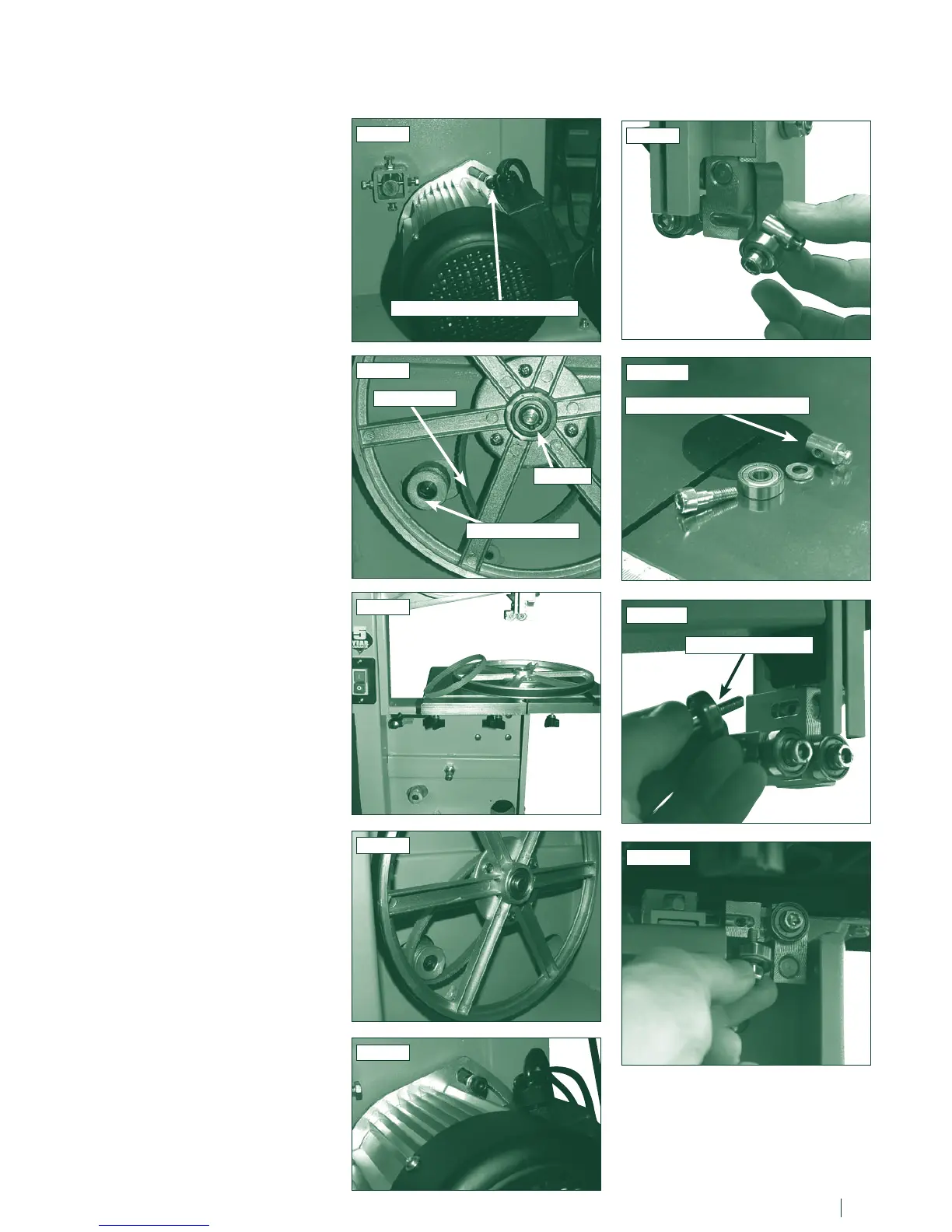

10.2 Replacing the drive belt

Note: Circlip pliers are required for this

procedure

To replace the drive belt

slacken the

tension on the belt by loosening the

motor pivot Allen bolt on the back of

the machine, lifting the motor and re-

tightening the bolt

Fig.10.4. Ease the

drive belt off the motor pulley

Fig.10.5.

Ensuring that there isn't a blade fitted

now remove the lower bandwheel

by releasing the circlip from the hub

Fig.10.6. Remove the old belt and fit the

new one

. Once the drive belt is in place

re-fit the lower bandwheel

Fig.10.7. Now

tension the drive belt by loosening the

motor pivot allen bolt and lowering the

motor until adequate tension is applied

Fig.10.8.

Tip: As a guide the belt is correctly

tensioned when using the index finger

to impart reasonable pressure on the

belt should not deflect more than 1/4".

But like tensioning a blade a bandsaw

blade this is subjective and the best

test is if the belt is not slipping or

wearing excessively and there is

adequate power being applied to the

bandwheels then the drive belt is

tensioned correctly.

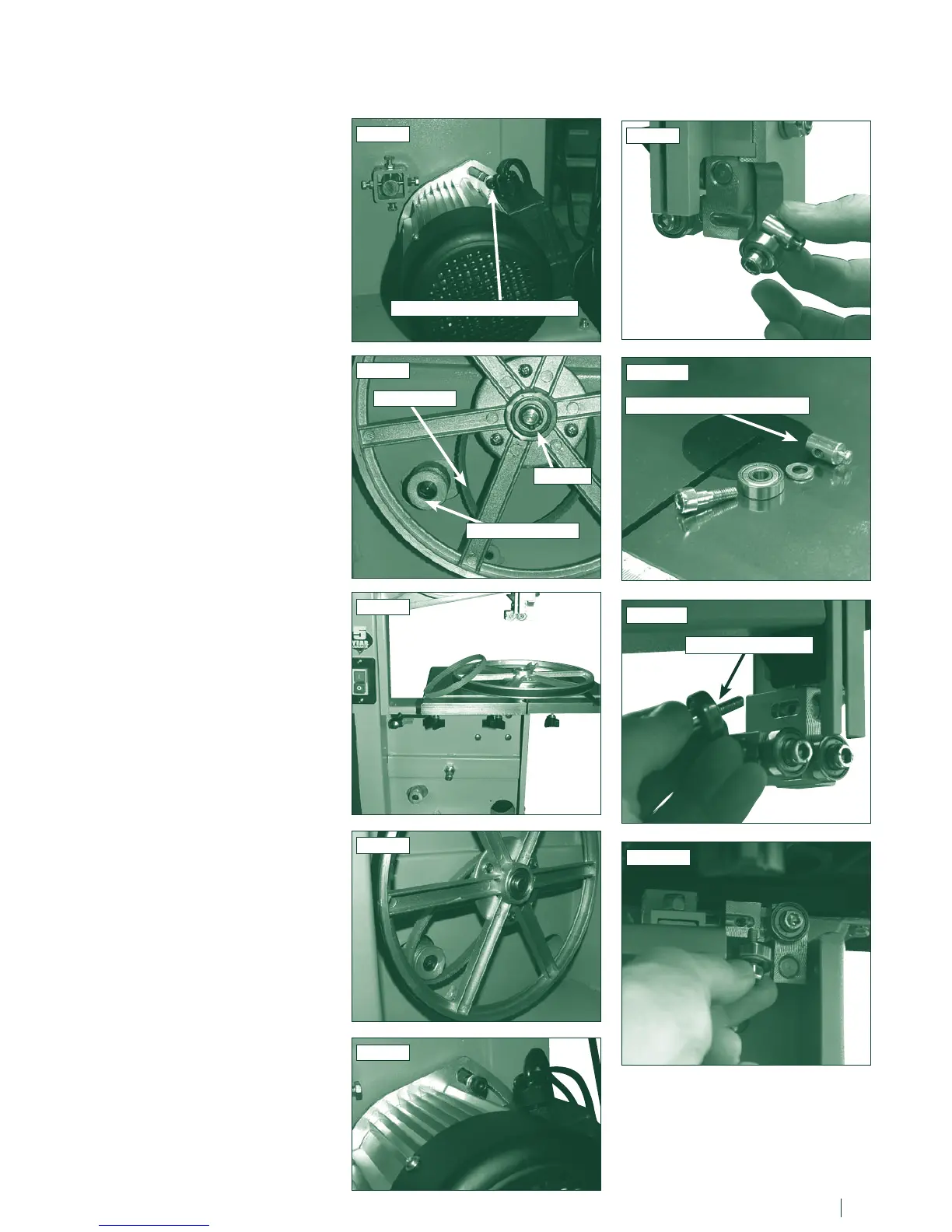

10.3 The blade guide system

In general usage it is advisable to

carefully apply silicone spray to the

blade guides to ensure free movement

of the rollers, do not use oil or grease

for lubrication as this will attract dust

and cause the rollers to jam. The blade

guide system is a consumable item and

depending on usage will wear and need

replacing.

CAUTION!

It is advisable that the blade has been

removed from the machine before

replacing the blade guide components.

When replacing components on the

upper guide assembly simply undo

the Allen bolt which is used to make

adjustment and slide the unit completely

out of the housing

Fig.10.9. This unit can

now be separated by unscrewing the

cylindrical slide piece

Fig.10.10. Replace

the bearing and reassemble.

To change the thrust bearing, undo

the Allen bolt completely and r

emove

Fig.10.11. The bearing itself can now be

replaced and refitted

.

When replacing components on the

lower guide assembly, undo the Al

len

bolt completely and r

emove Fig.10.12.

CAUTION!

Before carrying out any adjustments

or maintenance ensure that the

machine is isolated and disconnected

from the electricity supply.

10. Maintenance - cont.

Fig.10.4

Fig.10.5

Fig.10.9

Fig.10.10

Fig.10.11

Fig.10.12

Fig.10.6

Fig.10.8

Fig.10.7

MOTOR PIVOT ALLEN BOLT

DRIVE BELT

MOTOR PULLEY

CIRCLIP

CYLINDRICAL SLIDE PIECE

THRUST BEARING

24 25

Loading...

Loading...