18

Fig. 6.1A

A B

73

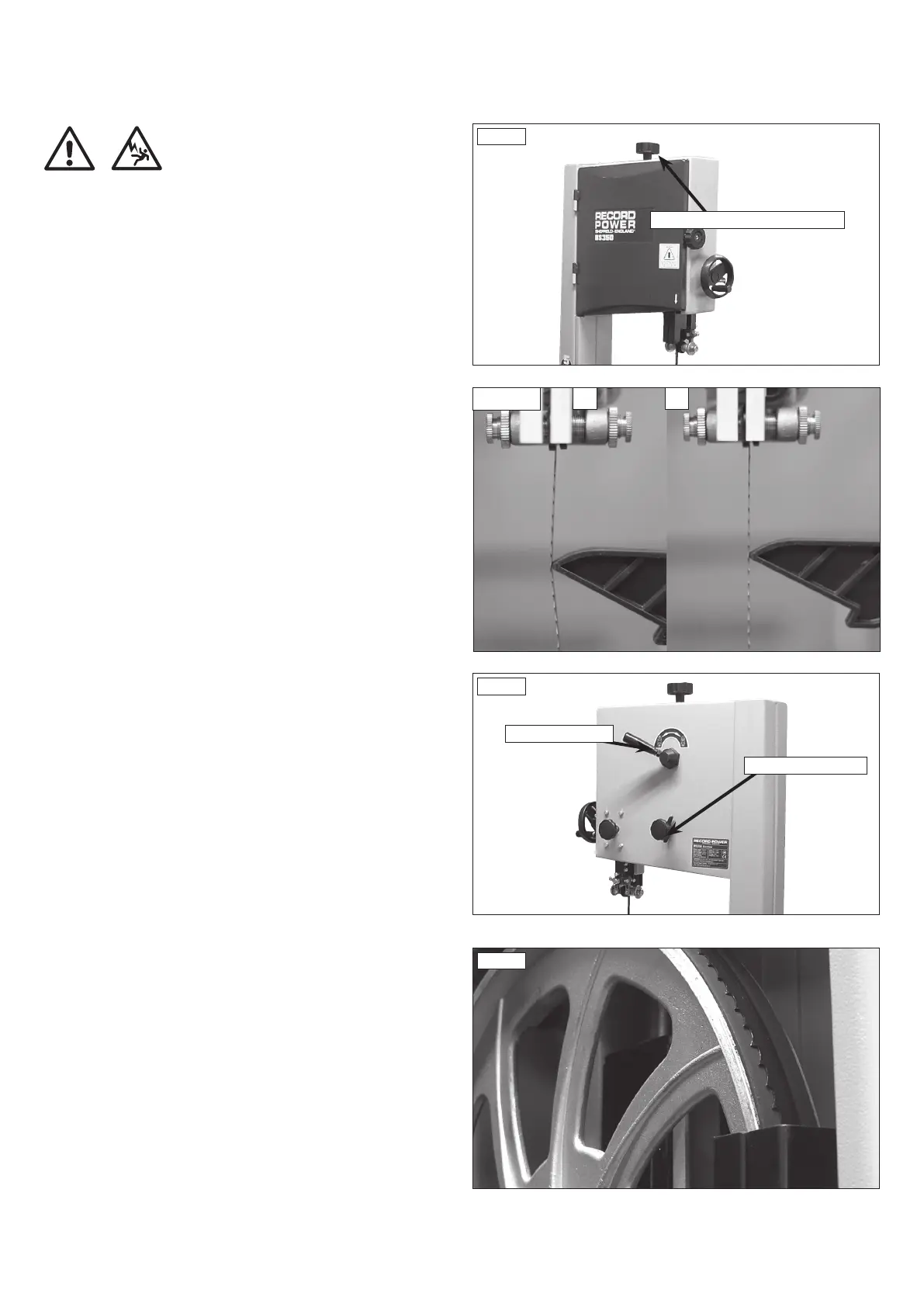

6.1 Tensioning the blade

The blade tensioning knob should be used to increase or decrease tension

(See Fig. 6.1). The only truly accurate way to check a blade is with a

tension meter. These are very expensive so most users may need another

method. The blade tension indicator which is located inside the main top

housing of the bandsaw, should be used first, as a guide to the correct

tension. We then suggest testing the tension by the amount the blade will

deflect sideways. First set the guides to 150 mm above the table, making

sure the saw is turned off. Push the blade sideways with a reasonable

amount of pressure using the push stick. A correctly tensioned blade should

not move more than 4 mm sideways, Fig. 6.1 A. If the blade is over-

tightened, as in Fig 6.1 B, the blade could be damaged.

However perhaps the most tried and tested way of blade tensioning is

simply: If the bandsaw is cutting accurately then the blade is tensioned

correctly, if the blade tends to wander and an accurate cut cannot be

achieved then the blade tension needs adjusting.

If the machine is to stand idle for a period it is good practice to slacken

tension and re-tension when next using. On the BS350 the simplest way to

release and re-tension the blade is to use the blade tension release cam

handle located on the back on the machine.

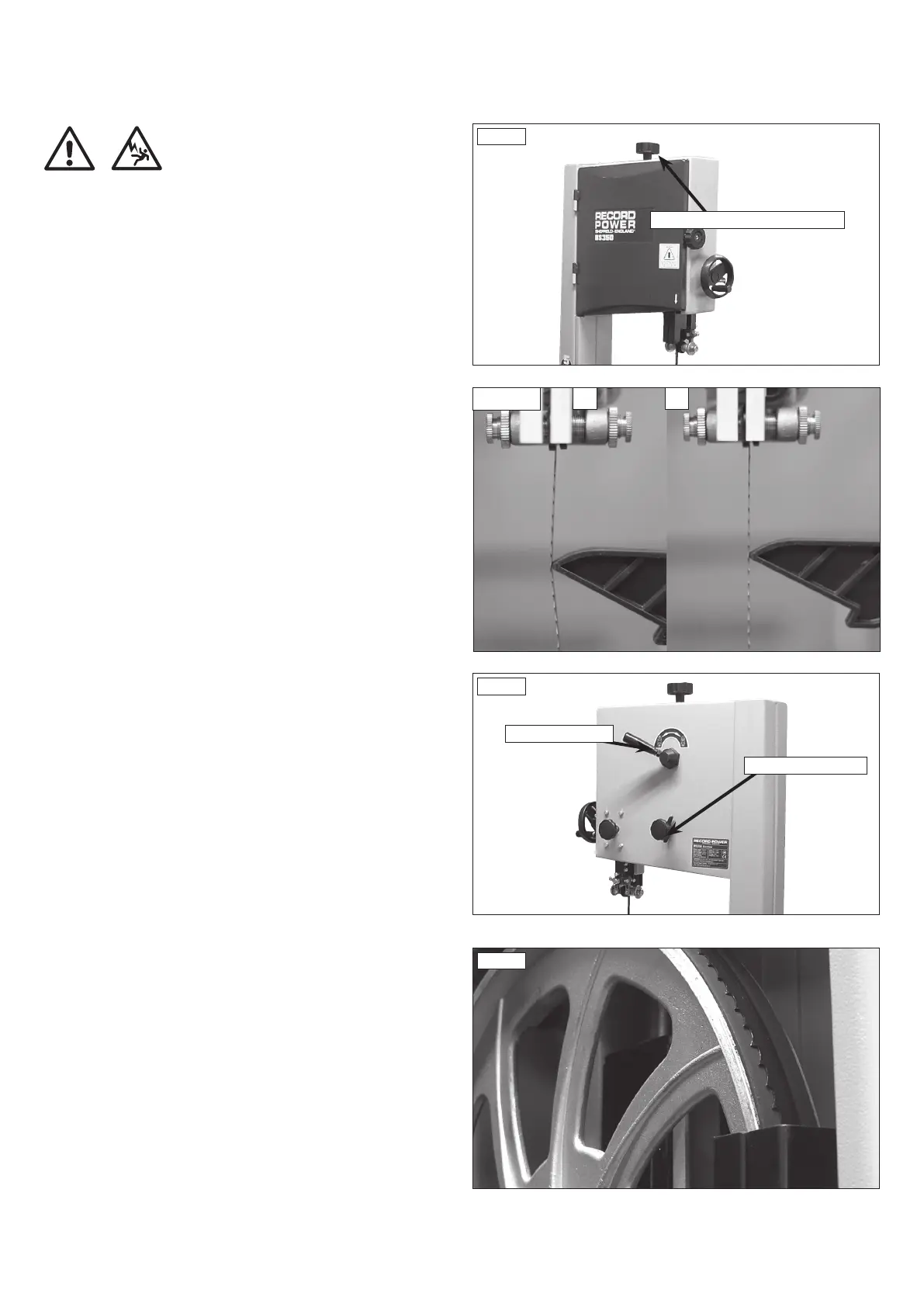

6.2 Tracking the Bandsaw blade

Isolate the machine from the supply by unplugging the mains plug. Set

the tracking of the blade before setting the blade guides. Once the blade

is tensioned, track the blade by turning the upper bandwheel by hand and

adjusting the tracking knob (See Fig.6.2). When viewed from the back

of the machine turning the tracking knob clockwise the blade will move

towards the back of the bandwheel, by turning the tracking knob anti-

clockwise the blade will move to the front of the bandwheel. The blade

should run as close to the centre of the bandwheel as possible, as shown

(See Fig.6.3). On narrow blades (eg. 1/4" and 3/8") it may be necessary

to run the blade to rear of the bandwheel. After the blade is tracked in

the desired position on the bandwheel, rotate the band wheel several

more times by hand without any further adjustment ensuring that the

blade remains in the same position. Once this has been achieved lock the

tracking knob with the winged nut (See Fig.6.2).

It takes a few revolutions of the bandwheel for the effect of adjustment

on the tracking knob to become apparent. To avoid over-adjusting, make

small gradual adjustments on the tracking knob and revolve the bandwheel

on a few times to check the effect before making further adjustments. The

machine should then be run for a few seconds before any adjustment of

guides is carried out.

Fig.6.2

Fig.6.3

CAM HANDLE

TRACKING KNOB

6. Bandsaw Blade Set Up

Fig.6.1

BLADE TENSIONING KNOB

CAUTION!

Before carrying out any adjustments or maintenance ensure

that the machine is isolated and disconnected from the

electricity supply.

Loading...

Loading...