16

3. SYSTEM COMPONENTS

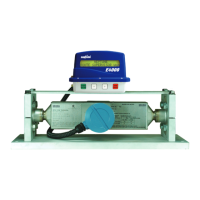

3.1. RML2000 Coriolis Mass Flowmeter

The Coriolis meter is mounted in a similar position to

a traditional volumetric meter at the rear of the truck.

The meter is connected in line via 2” 300 lb pressure

rated anges to the vapor release and differential

valve.

The meter is constructed from stainless steel and

consists of a double U-tube arrangement enclosed in

a rectangular case. The drive coil, used to vibrate the

tubes, and the sensor coils which measure the exing

of the tubes under ow conditions, are mounted inside

the box.

The instrument electronics are enclosed within the

small junction box at the top of the meter. Power and

communication connections to the register are made

here. The only means of communicating directly to the

Coriolis meter is to connect a computer to these same terminals. The computer is only required to “zero”

the meter as part of the calibration process, to be discussed later in this manual.

Once the junction box lid is closed, there are no operator controls on the meter; all functions are per-

formed at the E4000 register head.

3.2. E4000 Register Head

The E4000 electronic register is designed and eld proven to

withstand the harsh environment on tank trucks. The enclosure

is plastic with a NEMA 3 rating.

The E4000 can be mounted directly on the positive displace-

ment owmeter so that the mechanical drive of the meter rotates

an optical pulse encoder mounted in the register. Alternately,

the register can be mounted wherever required when receiving

a pulse output from a meter. Counting the pulses indicates the

amount of product measured by the owmeter during a delivery.

An optional temperature compensation kit can be added to the

base unit.

An operator communicates with the register via an LCD screen and a 4 button control panel. Internally

mounted relays operate electrical solenoid valves to control the ow of product. Delivery ticket information

is transmitted through the power/data cable from the rear of the register to a cab mounted junction box,

then to the ticket printer or hand-held computer.

Power and data connections are made to terminal strips inside the register and junction box. Congura-

tion parameters are programmed into the register manually by the buttons or from an external computer

using the E4000 conguration program.

An internal calibration switch is positioned inside the register to allow access to the Weights and Measures

conguration menu, and is mechanically sealed on the outside of the register.

Figure 3-1. RML2000 Tube Conguration

Figure 3-2. E4000 Register Head

Loading...

Loading...