44

13. If the readings are acceptable, return to Prolink, Conguration, and under the Flow tab, change the

mass and vol ow cutoffs back to the original values (6.4000 lb/min Mass Flow Cutoff and 5.00000 gal/

min Vol Flow Cutoff). Note: This is very important. Failure to do this can result in the meter advancing the

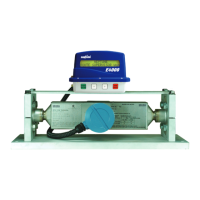

E4000 totalizer, even though there is no ow through the meter.

14. Power down the system and disconnect the hardware from the meter transmitter to exit the Modbus

mode, and enter the pulsed output mode. Note: Until you exit the Modbus mode, no pulses will be sent

from the meter to the E4000 Electronic Register, and therefore no gallonage will be shown on the E4000

when pumping through the meter.

15. The zeroing operation is now complete, and when the system is powered back up, it will have a pulsed

output to the E4000. Open the valves, and calibrate the meter K factor using the E4000 Electronic Regis-

ter.

16. To ensure that you have successfully zeroed the meter, it is very important to test the meter at both a

high ow and low ow (82 GAL max. and 8 GAL min. for the RML2000). Note: While lling the volumet-

ric prover, do not allow the meter ow rate to decrease to less than 5 GPM, or the test results will not be

accurate. If there is no more then the allowed W&M spread (usually 1% maximum) between high and low

ow, the zero is acceptable. If greater than 1%, the meter should be zeroed again.

5.4 Calibrating the E4000 Volumetric K-Factor

Before calibration, see Section 5.3 for the RML2000 zeroing procedure.

NOTE: Software versions 08 and higher permit W&M inspectors to check calibration by viewing

both the gross and net volumes for the last delivery, without breaking the seal to enter the W&M

menus. If the ^ or > buttons are pressed after the delivery ticket is printed, but before the cancel

button is pressed to return to the SELECT PRODUCT screen, the screen will display both the gross

and net volumes. If calibration is required, it is recommended that a shift report be printed before

and after the calibration procedure, in order to reconcile the customer’s inventory. The shift

reports will show the totalizer readings at the start and completion of the calibration process. Any

quantity pumped through the meter during the calibration process will be added to the register

totalizer reading.

To print a shift report:

1. From the NEPTUNE root menu, press either > or ^ on the four button front panel, until ROUTE is

ashing, then press the START/ENTER button.

ROUTE SUPERVISOR W&M

Loading...

Loading...