51

6. INSTALLATION CHECKLISTS

Junction Box

___ Mount the Junction Box in cab oriented so that the two RS232 ports are easily accessible,

and Jbox cover can be easily removed to access terminal connections.

___ Route power/data cable thru center port, printer power cable thru left port (RS232

connector side), and truck power cable thru right port.

___ Tighten three plastic cable glands to prevent pulling cables from JBox.

___ Check wire color connections as shown in the wiring diagram and tighten all terminal connections.

___ Connect the shield wire to the REGISTER PRINTER DATA terminal connection.

**Do not allow the bare shield wire to contact the metal junction box.**

___ Attach “TRUCK POWER +12 VDC” to a switched accessory circuit on the truck fuse

panel, using a 16 AWG cable with an in-line 5 amp fuse.

___ Attach TRUCK POWER COMMON to the negative terminal of the battery, using a 16 AWG cable, and

verify that the resistance from the terminal connection to the negative terminal of the battery is less

than 1 ohm (measured with power to the E4000 system switched off).

___ Attach TRUCK FRAME connection as a separate wire (not same wire as TRUCK

POWER COMMON) to the negative terminal of the battery, using a 16 AWG cable, and verify that

the resistance from the terminal connection to the negative terminal of the battery is less than 1 ohm

(measured with power to the E4000 system switched off).

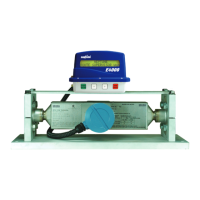

Register

___ Attach to meter and tighten all connections (Section 4.5)

___ Install and wire RTD, if equipped (Sections 4.6 & 4.7, LPG).

___ Install rubber gaskets on the plastic cable gland and metal liquid tight connector so that the gaskets

are positioned on the outside of the register.

___ Route power/data cable thru right side port at rear of register (looking from the rear), and tighten the

plastic cable gland to compress the rubber gasket.

___ Route valve cable (if equipped with valve) thru the left side port (nameplate side), and tighten the

metal liquid tight connector to compress the rubber gasket.

___ Check the hole plug in the center port for correct installation and tighten.

___ Cut and remove the shield wire from the power/data cable to within 1 inch of where the cable enters

the register base. **Cut the shield wire on the register end of the cable only, not on the Jbox end**.

____Route the wires for the HHC and PRINTER around the left side (from front of register) and connect to

the terminal strip on top of register (See Figure 4-13).

___ Route the appropriate wires across to the right side of the register and connect to the terminal strip on

the side.

___ Check wire color connections (See Figure 4-13) and tighten all connections.

___ Check the voltage across terminals 23 and 24 and verify it is 12-14 VDC.

___ Check to be sure the display ribbon cable connectors are attached securely.

Printer

___ Set DIP switches all to OFF (See Figure 4-20).

___ Install printer ribbon.

___ Mount the printer in the cab.

___ Plug the printer power connector into the round DC24V port on back of printer.

___ Plug the 9-pin connector on the printer data cable plug into the RS-232 socket on the rear of the

printer.

Loading...

Loading...