21

The meter may be mounted for either left or right handed ow; however, the ow of liquid through the

meter must always be in the direction indicated by the arrow on the meter housing. (Left to right ow when

the unit is viewed with the nameplate on the right.)

Isolate the meter with valves upstream, downstream, and in the vapor return line, as close to the meter as

practicable. The valves are required to ensure the meter remains lled with propane during the “zeroing”

procedure. (see section 5).

Use exible hose (min. length 8”) for connections to both the inlet and outlet of the meter to eliminate

stress on the meter due to misalignment of piping. (See Figure 4-2, tank to meter inlet, and Figure 4-3,

differential valve to hose reel.).

Figure 4-2. Flexible Hose at Inlet Figure 4-3. Flexible Hose at Outlet

4.5. Installing a Retrot RML2000 Mass Flowmeter

The installation procedure for a retrot RML2000 is essentially the same as for a new installation. The

vapor release and differential valve from a previous Neptune 2” 4D-MT meter can be reused. If the prior

installation used mechanical temperature compensation, the installer will be required to replace the strain-

er cover with one that accommodates the E4000 thermowell. (See section 4.7, Installing the RTD). The 80

mesh strainer can be replaced with 16 mesh. (80 mesh is acceptable but will result in reduced ow and

more frequent cleaning,)

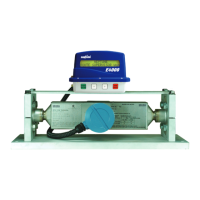

4.6. Positioning the E4000 Register Head

The RML2000 bracket supplied by Red Seal

provides a mounting plate with pre-drilled holes

for the E4000 (gure 4-4). If this bracket is not

used, the installer will be required to manu-

facture a custom xture to secure the register.

When considering a position for the bracket,

ensure that the register controls will be easily

and safely accessible by a driver. Also, the RTD

probe cable must reach to the vapor release

strainer cover as discussed in Section 4.8, Wir-

ing the RTD.

Figure 4-4. E4000 Mounted on Bracket

Loading...

Loading...