9

2 INSTALLATION

2.7 Cable sizing

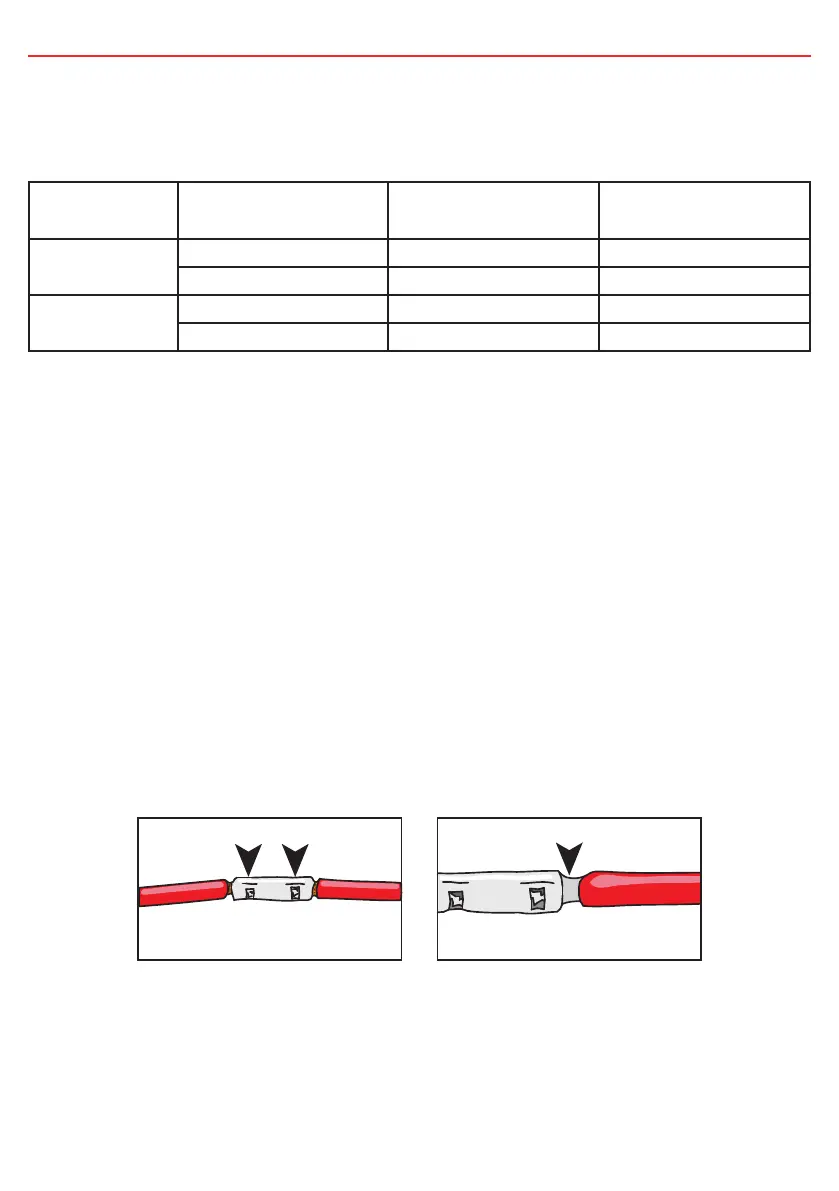

Below is a table outlining the required cable size for a given cable install length.

Always choose a wire diameter equal to or greater than what is specified below.

Part Number Cable Install Length

(m)

Recommended Wire

Size (mm²)

Closest (BAE, B&S,

AWG)

BCDC1225(-LV) 1 - 5 7.71 8

5 - 9 13.56 6

BCDC1240(-LV) 1 - 5 13.56 6

5 - 9 20.28 4

2.8 Wiring

The heavy gauge wires on the BCDC1225(-LV) and BCDC1240(-LV) unit carry

peak currents of up to 35 and 50 Amps respectively, and it is important to make a

good, low resistance, electrical connection that will not degrade over time. Failure

to make a good, reliable contact may result in breakdown of the wire insulation

and cause a short circuit, or worst case a fire. We recommend that this activity be

undertaken by an appropriately trained person.

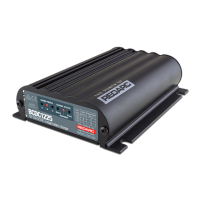

REDARC recommends using a soldered butt splice crimp connection that is

covered with heatshrink. See Figure 2.8. REDARC does not recommend using

standard red/ blue/yellow blade connections as they are not rated for either the

current required or gauge of wire supplied on the unit.

Crimping provides good mechanical connection, soldering provides a long lasting

electrical connection and forming of the heatshrink will prevent any shorting/

contact with your vehicle chassis.

Figure 2.8 - Ensuring a good wiring connection

Crimp here.

Crimp both wires to the butt splice using

indent type crimpers.

Solder Both Ends Here.

Solder the wires to the butt splice.

Ensure that a good connection is

made. Keep heatshrink away until after

soldering is complete and has cooled.

Loading...

Loading...