Page 18 of 28

4. If either light sensor is not reading the correct value in the Raw Data Stream (“Nozz” and “Final” diameter

readings) then the light guides require adjustment by sliding them forward and aft.

5. Both light guides V1.0 and V1.1 have a screw on their side, facing to the users right. In both cases, loosening

this screw allows the light guide to be slid fore and aft, which in turn decreases or increases the reading

respectively. To be clear, sliding the LED mount back towards the user increases the diameter reading.

Conversely, the diameter reading will decrease as you move the slider carriage closer to the sensor. This is

how you achieve nominal reading based on your dowel’s true diameter. This is only effective if the angle of

the LED is correctly aligned.

In all likelihood you will only have to adjust the LED’s angle. This is more subject to movement if

accidentally bumped compared to the slider position.

Note the nozzle sensor’s reading can be a little “off” from nominal - up to 0.1mm - and still operate just fine.

The software will adjust the puller speed accordingly. What is critical is that the final diameter sensor’s

reading be as accurate and precise as possible.

Diameter sensor alignment can be a bit of an iterative process. Sliding the LED mount forward or backwards may

necessitate repeating Step 2, evenly lighting the sensor. Similarly, If the sensor itself is moved up or down, and

adjustments are required to evenly light the sensor, the sensor should be re calibrated (Step 3) to ensure a correct

reading. Ultimately, you want to achieve Figure 14’s response for both sensors - the key points are that the shadow

is right in the middle of the sensor response pattern, that the pattern is a flat line at 255 where it’s not blocked by

the filament, and that the diameter reading is exactly accurate as reported.

4.0 Extrusion Operational Instructions

4.1 Overview

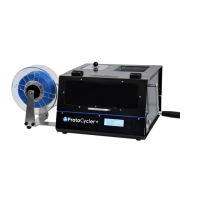

Now that we are all tuned up and have assured our ProtoCycler is clean and diameter sensors are aligned, we can

extrude filament! We will guide you through Automatic Mode Extrusion and Manual Mode.

Before starting either automatic or manual extrusion, please make sure you’ve setup your Spooler correctly,

including Step 10 of Spooler Set Up (setting spool dimensions on the ProtoCycler). If this step is not taken then

the filament will not spool nicely.

Please be sure to operate your ProtoCycler in a clean, dry environment, at ambient air temperature (~23C is ideal

temperature for your room to be). We recommend you maintain ambient room temperature conditions as that is

the average temperature ReDeTec calibrates each ProtoCycler in.

Note every unit is primed with plastic (PLA or ABS depending on what you purchased) and calibrated before leaving

ReDeTec. This means there is plastic already in your melt section! Depending on how much time has passed since

the ProtoCycler was calibrated, the plastic in the melt section may have absorbed moisture from the air. If too much

moisture has been absorbed into the melt section plastic, purging may be required - simply run the unit for ~10

minutes to flush out the old plastic with new, dried plastic.

4.2 Initial Extrusion Steps for both Manual and Automatic:

1. Fill your hopper with dry plastic and colourant of your choosing (if any). Remember colourant is critical if

the plastic you are processing is naturally clear when melted (PLA extrudes transparent for example). Mix

1 tablespoon of colourant for every 500g of plastic.

2. After powering on ProtoCycler, choose whether you would like to connect to your computer or not.

Loading...

Loading...