99

Control units VCS

PLC Controller for Compressor Output Control

Safety Measures

Check the correct supply voltage (see Technical Data) before

connecting the device. Do not expose the device to moisture

or water. Use the devise so that the operating conditions

will not be exceeded and the device will not be exposed to

abrupt changes in temperatures at high humidity causing air

humidity condensation.

Warning: Disconnect all power supply connections before you

start any maintenance work on the device.

e sensors must be located out of reach of the end user. Do

not disassemble the device. If the device fails or malfunctions,

send it back, including a detailed description of the failure.

General Description

e PLC controller controls cooling in the air-conditioned room

depending on the signals received from the parent system

and pre-set parameters. It measures temperature in the

compressor discharge and pressure in the heat exchangers.

If the device is fitted with a 4-way valve (Premium" version),

it is possible to switch the unit between cooling (in summer)

and heating (in winter) modes of the ventilated room, including

heat recovery. For a more detailed description of this technol-

ogy, refer to the User Manual. e device is equipped with

preparations for a differential pressostat in the air-handling

unit channel, serving as antifreeze protection of the evapora-

tor. e signal received from this switch will start defrosting

by directing inlet air to the evaporator's fins. Defrosting starts

automatically if the limit evaporation temperature is set below

4°C, when ice build-up is created on the evaporator's surfaces

which need to be defrosted. If the differential pressostat is not

present, defrosting can also be set for time cycles using the

parameters. Evaporation pressure is used to monitor the de-

vice and the unit's output is reduced to protect the evaporator

against freezing at low evaporation temperatures. Condensa-

tion pressure monitoring is another way of providing device

protection. When this value is increased, the unit's output is

reduced to prevent a failure. e output reduction is signalled

by the relay contact – KA7. e output reduction level can also

be signalled by 0-10V analogue outputs. One signal's reduction

is based on the evaporation temperature and the other one is

based on the condensation temperature. e device is able to

control condensation pressure using an analogue output. is

feature is only available for the "Premium" version.

Process Control

Control is started as soon as the contacts for the unit start are

closed. Relay – KA9. If the unit is equipped with reversation,

the cooling or heating mode is selected.

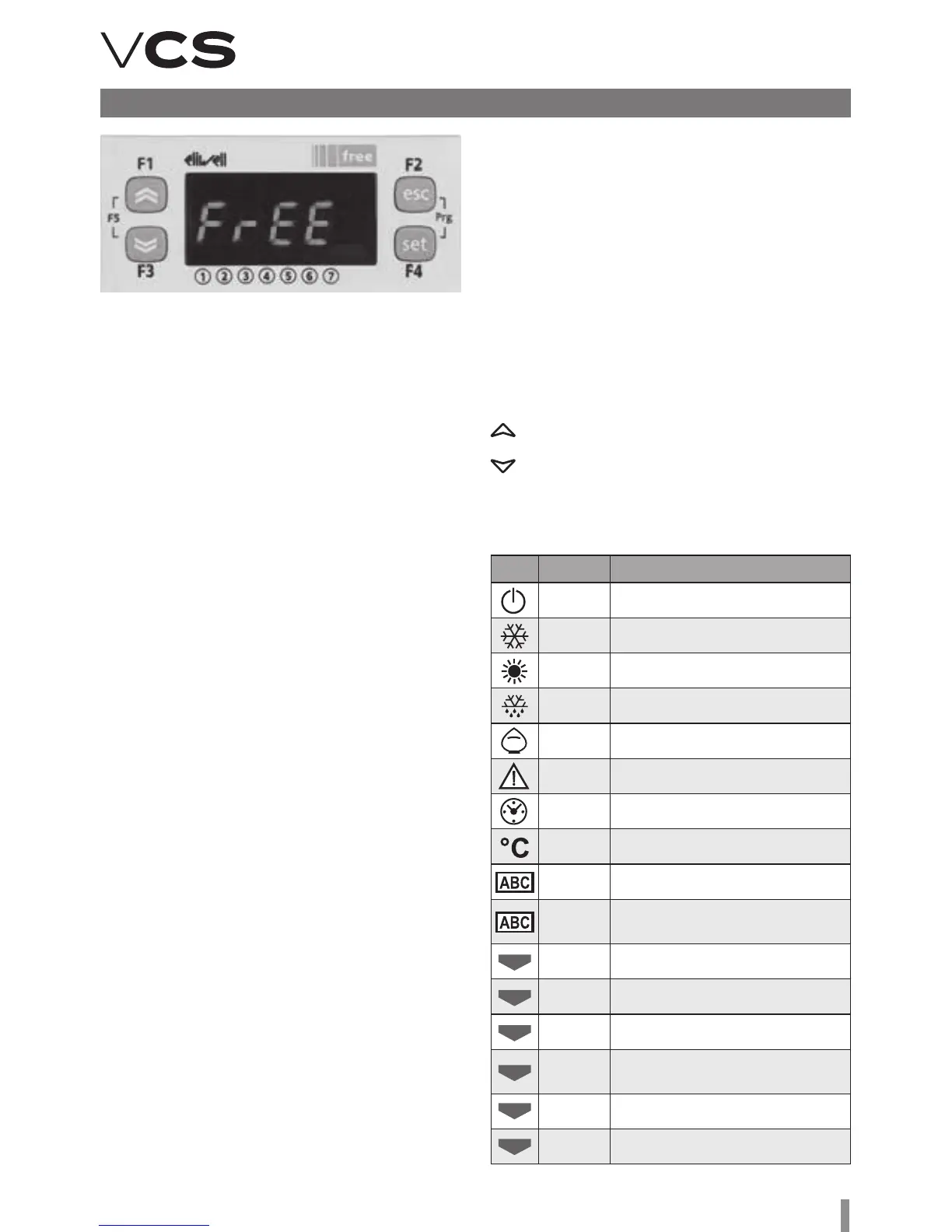

LED Mode Function

On Unit start is requested

On Cooling in operation

On Heating in operation

On Defrosting in progress

On Power valve switched on

On Alarm

On No function

On Measured units

On Programming Menu

Flashes

Remembers the Prog. Menu password

for 60 s

1 FA1 circuit breaker open

2 FA2 circuit breaker open

3 Low-pressure pressostat open

4

High-pressure pressostat open or

incorrect phase sequence

5 Electronic injection valve failure

6 Output limiting relay closed

e selection is made by the relay – KA11 (closed = heating).

en the unit output is controlled by the 0-10V analogue

signal. Operation of the unit is indicated by a dry contact,

the same way as an error. e unit is equipped with several

protections, protecting the cooling device against damage

(pressure switches, outlet temperature monitoring, etc.).

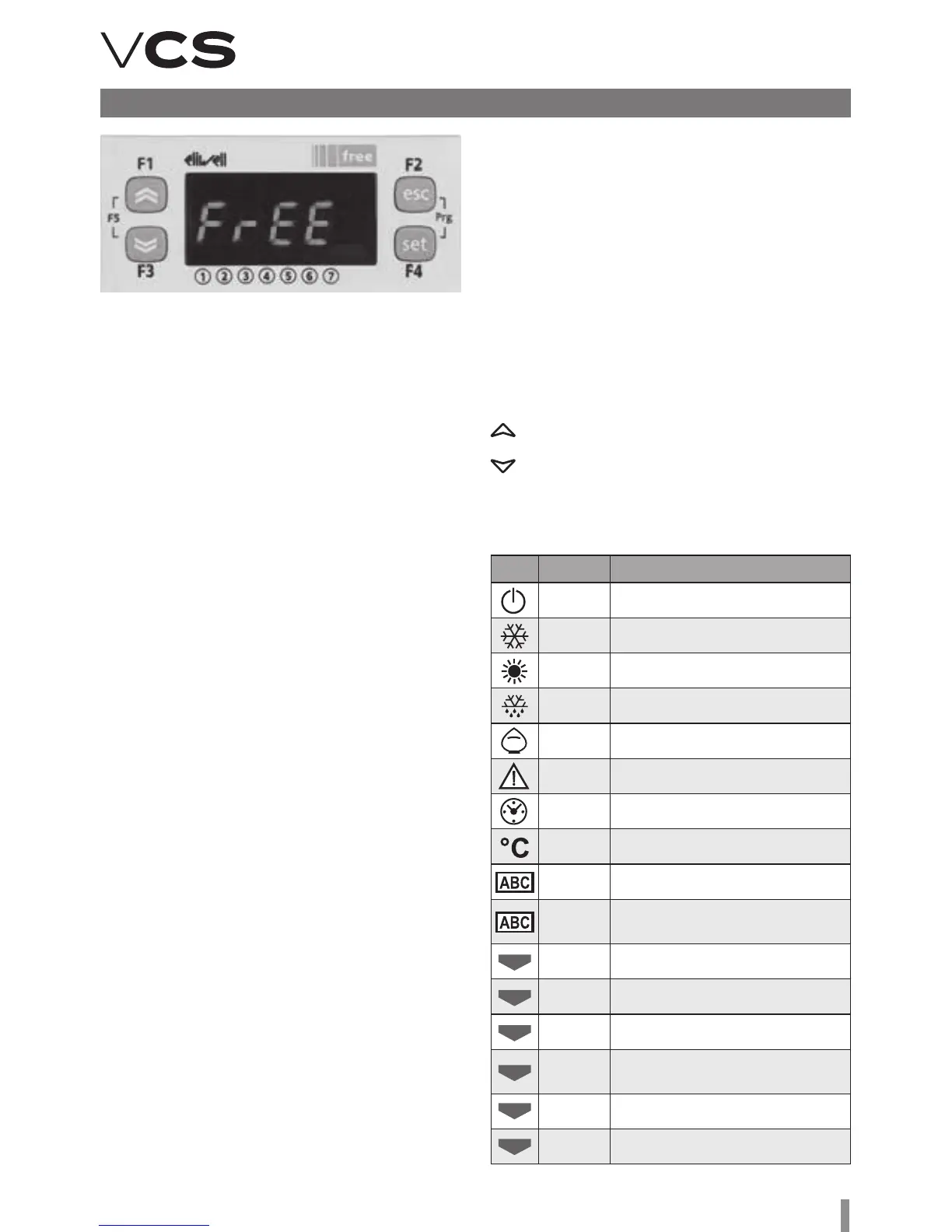

Controller Operation

SET(F4) Shows the user parameters.

In the programming mode, it is used to select

the parameter or confirm the operation.

ESC(F2) In the programming mode, it is used to cancel

the operation. Cancels the action.

Long hold = Failure reset

(F1) No Function

(F3) No Function

Key combination:

SET(F2) + Esc (F4) Enters the programming mode.

Loading...

Loading...