16

Control and Protection Functions

Fan Speed Control

e VCS control unit enables either soware or manual air

output control, i.e. the speed of the following fans:

n Single-speed fans (ON/OFF control)

n Two-speed fans (two-stage control)

n Single-speed fans’ backup (ON/OFF control)

n Five-stage TRN voltage controllers

n Fan frequency inverters using the Modbus bus – five-stage

control

A standard control can be completed with a 3rd auxiliary fan

which is controlled from the outlet or inlet fan depending on

the control unit configuration.

Two-Speed Fans

e two-speed fans are always started using the first stage

at the air-handling unit start-up. e transition time from the

first to second stage can be adjusted. e transition time can

also be adjusted for the reverse transition from the second

to the first stage.

TRN Voltage Controllers

e control unit enables the voltage controllers to be con-

nected and controlled in five output stages. Depending on the

request, inlet and outlet control can be common or independ-

ent. e required output stage is always set in common. If

the fans are controlled independently, it is possible to set the

outlet controller correction against the inlet controller (see

the Data Point Settings – TRN Correction). However, the

control unit must be specially manufactured for this function

(depending on the customer request). Either the same cor-

rection can be set for all the speed stages or for each speed

stage independently. For the correction settings, refer to the

chapter Optional Function and Mode Settings.

Frequency Inverters

For five-stage control devices, the request for the inlet and

outlet fan speed is set in common. However, for frequency

inverters, the request for the inlet and outlet fan output

(0-100%) can be set separately for each stage (1 to 5) (see

the Data Point Settings – Fans).

Single-Speed Fan Backups (ON/OFF Control)

e backup motor is started if the main motor fails. e

backup is used either for the inlet or outlet fan, respectively

for both. e motors are equipped with thermal protection

(thermo-contact) and current protection. If the backup mo-

tor has been started, it is not possible to restart the main

motor without resetting the failure. e main and backup

motor current protection has a delay pre-set. Switching from

the main to backup motor is immediate without delay if the

main motor fails.

Backup fan control via Modbus communication bus

Using the Modbus communication bus, the five-stage fan

control enables a backup fan or a pair of backup fans to start

up if the main fan fails. If the backup fan or pair of backup fans

fails, the air-handling unit will be shut down. Information about

air-flow failures and motor overheating is sent via the Modbus

communication bus and signalled accordingly.

e fan speed control parameters are available through the

HMI controller in the List of Data Points in the section Settings

– Fans (inlet fan backup, outlet fan backup, TRN correction).

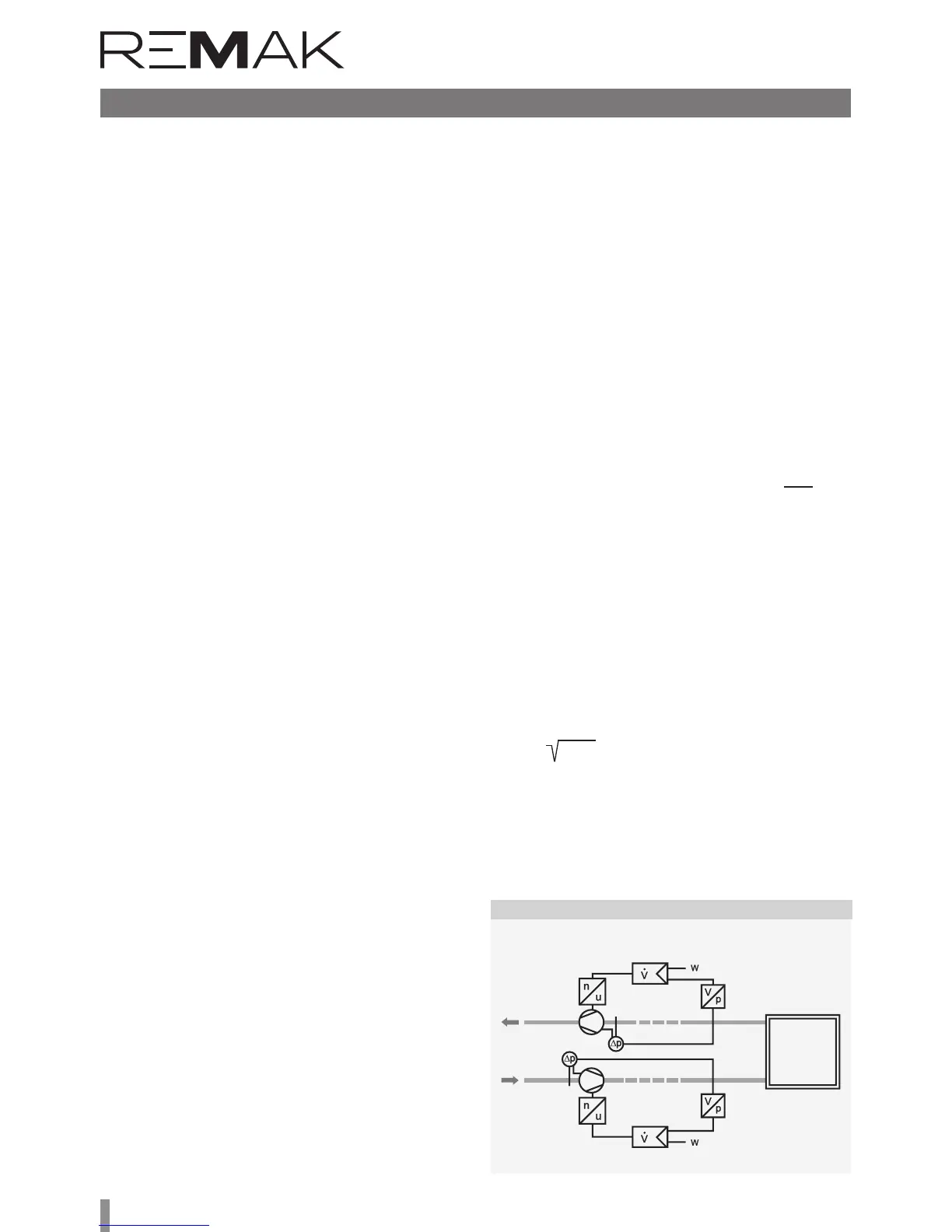

Constant Air Flow/Pressure Control

When designing constant flow, pressure, overpressure and

underpressure control, it is advisable to consider the overall

design of the air-handling unit, respectively application of the

mixing damper, and how the control behaviour can affect the

measured pressure value.

Constant Air Flow Control

Fan speed is controlled depending on the desired air flow rate

(m

3

/h). e air flow rate (air pressure in the diffuser recalcu-

lated to the air flow rate using the "k-factor") is measured by a

sensor; the control system evaluates this value and compares

it with the required value. e resulting fan speed is controlled

so that the required air flow rate will be reached at the point

of measurement (fan diffuser).

It is necessary to set the following pressure sensor pa-

rameters (see the Sensor Operating Manual):

n Mode (for CPG = Mode 5.00)

n Measuring range: As needed

e correct range can be determined

using a formula:

(where k = "k-factor", Vmax = designed air flow rate of the

device). e correct sensor range is then set according to the

calculated pmax value.

n K-factor of the respective fan

It is necessary to set the following parameters of the VCS

control Unit (see List of HMI Data Points):

n Air flow sensor measuring range – (maximum value from

the CPG air flow sensor in m

3

/h)

n is can be calculated using the formula or read from the

CPG sensor menu (see the Sensor Operating Manual).

n e maximum measured air flow rate can be calculated

according to the following formula:

V

max

= k × DP

max

Example: K-factor = 308, Maximum sensor range Pmax =

2000 Pa, Vmax = 13774 m

3

/h. is value is then entered

as the maximum range of the sensor in the VCS using HMI.

Note: In AC, the "Max. Air Flow Rate" is stated for the fan as-

semblies. Attention! is is not the maximum range of the air

flow sensor to be entered in the VCS control unit.

Dp

max

=

V

2

max

k

2

Figure 15 – Constant Pressure Control

Loading...

Loading...