17

Control units VCS

Basic Information on VCS

Operating Modes

Operating states

ere are three operating states defined for VCS control units

(Stop, Run, Auto):

Stop – e device is in standstill mode (fans stopped). Impor-

tant safety features like antifreeze protection and moderate

pre-heating of the water heater are retained.

Run – e device is started in accordance with the pre–set

temperature mode and fan speed.

Auto – Control is switched to the next operating mode with

a lower priority. e Auto operating state cannot be set in

the time schedule mode because it is a control type with the

lowest priority.

e operating mode determines which operating state will be

active according to priorities (see Operating Modes).

Operating Modes

e control unit’s operating state (i.e. whether the air-handling

unit is in the Stop or Run state) is determined by one of the

operating modes (manual control, external control, HMI-SG

controller, BMS or time schedule modes). HMI-DM or HMI-TM

controllers affect control in the manual control mode. External

control is performed by single- or two-contact control. BMS

control enables control of the control unit by the higher level

control device (e.g. smart building control systems; Note:

pending). To control air handling systems, the HMI-SG control-

ler is connected to the control unit.

e operating mode which will determine the device’s oper-

ating state (Run or Stop) is determined by the priority. Each

operating mode is assigned a priority, i.e. the first option to

control the control unit, to eliminate mutual interference. e

operating modes are prioritized as follows, from the lowest

to highest priority:

n Manual control

n External control

n Local HMI-SG controller

n BMS (pending)

n Time schedule

n Additional operating modes

e priorities and entire control system are shown in the

diagram on the following page.

Control and Protection Functions

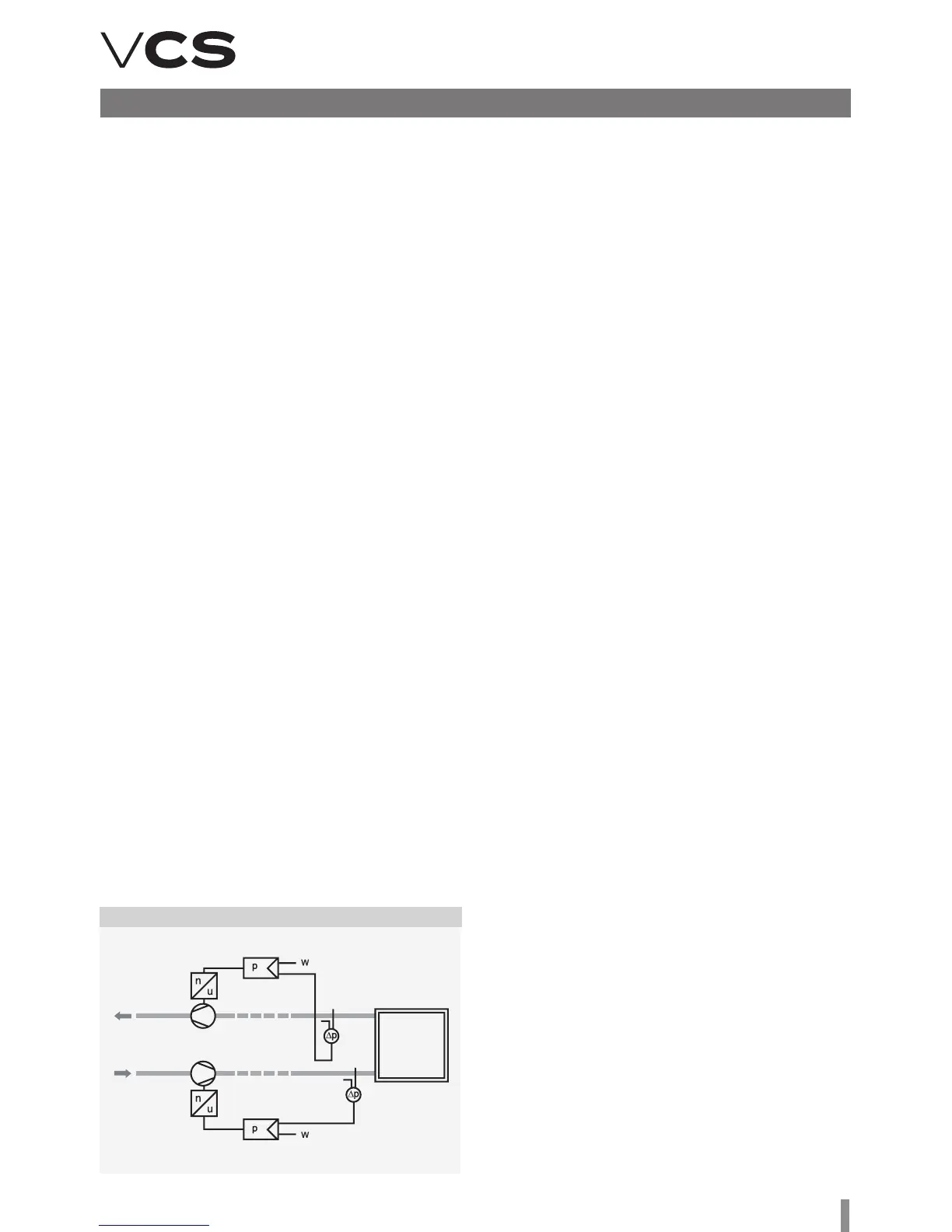

Figure 16 – Constant pressure control

Constant pressure control

Fan speed is controlled depending on the desired air pressure

(Pa). e air pressure is measured by a sensor; the control

system evaluates this value and compares it with the required

value. e resulting fan speed is controlled so that the required

air pressure will be reached at the point of measurement.

It is necessary to set the following air flow sensor param-

eters (see the Sensor Operating Manual):

n Mode (for CPG = Mode 4.00)

n Measuring range: As needed (200 Pa, příp. 1000 Pa)

It is necessary to set the following parameters of the VCS

control Unit (see List of HMI Data Points):

n Air pressure sensor measuring range – (maximum value

from the CPG air pressure sensor in Pa)

n Required values (separately for the inlet and out-

let fans). 5 required values are available for selection.

Constant Air Flow + Overpressure in the Room Control

e inlet branch (fan) is adjusted to the constant air flow so

that the required air volume is delivered to the room. e outlet

branch is adjusted to the required difference in overpressure in

the room. us, the outlet fan is adjusted to the required pres-

sure (overpressure) depending on the pressure sensor location.

Application: Preventing dirt from entering the room.

Constant Air Flow + Underpressure in the Room Control

e outlet branch (fan) is adjusted to the constant air flow.

e inlet branch (fan) is adjusted to the difference in under-

pressure in the room. us, the inlet fan is adjusted to the

required pressure (underpressure) depending on the pressure

sensor location.

Application: Preventing dirty air from entering the adjacent

rooms

Note: When commissioning the system, it is necessary to

perform the settings and regulation of the device (PID con-

stants, FI ramp, etc.)

n Number of fans (for twins = 2). e air flow rate of one fan

is measured and is then multiplied by the number of fans.

n Required values (separately for the inlet and outlet fans)

5 required values are available for selection.

Loading...

Loading...