95

Control units VCS

List and Description of Basic Data Points

Connection to the Master System (BacNet Standard)

BACnet/IP (BMS)

e VCS control unit enables integration of the centralized

BMS (Building Management System) using the BACnet/IP

communication standard. Using a suitably integrated mas-

ter system, it is possible to control the air-handling device's

operating state.

Generally

BACnet is a standard communication protocol for Building

Automation and Control Networks developed by ASHRAE

(American Society of Heating, Refrigerating and Air-condition-

ing Engineers). e main goal was to create a protocol which

enables the integration of systems from different manufactur-

ers intended for building automation. For detailed information

on the BACnet protocol, refer to the following websites:

www.bacnet.org

www.bacnetinternational.net

BACnet/IP Protocol

ere are several variants of the BACnet protocol. e VCS

control system uses BACnet/IP for the Ethernet network.

The BACnet communication protocol works using the

Master/Slave principle. e Server function is used for VCS

unit system communication with the master system. is

means that the VCS control unit behaves like a Server in the

communication.

Protocol settings can be performed using one of the follow-

ing controllers: HMI, DM, TM or Web. Switching on and off,

restart and other settings of the BACnet server can be carried

out through the web page (calling the address set in the VCS

control unit). For detailed information on the BACnet/IP Stand-

ard (EDE file and others) settings and application, refer to the

Siemens BACnet/IP Communication Module documentation

available on the REMAK website.

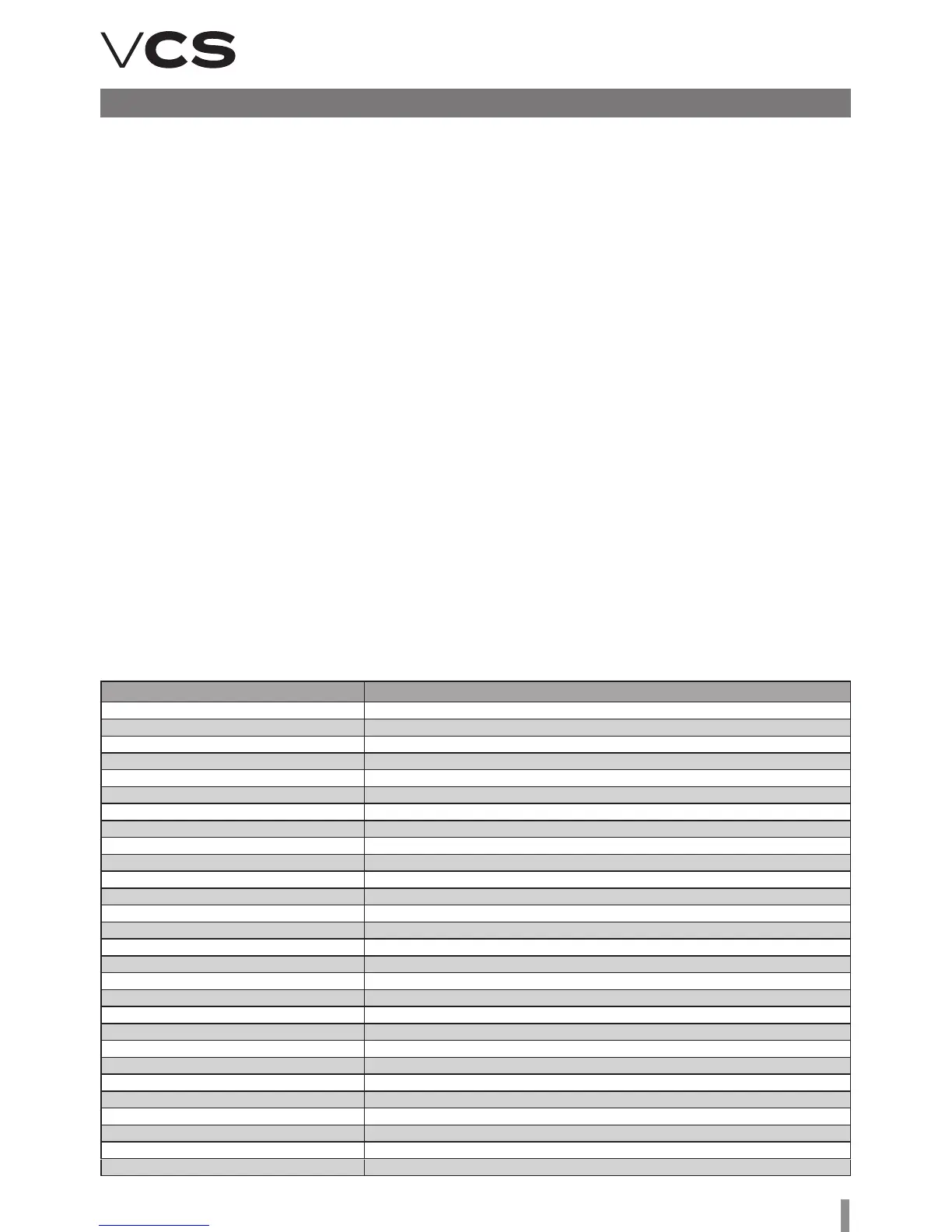

e following table includes a list of basic data points which

can be used for this communication and their description.

e list includes specifications of variables for different VCS

control system variants.

For example, if the VCS control system (air-handling device)

has not been equipped with gas heating, it will not be possible

to use these variables. e final functionality, monitoring and

control options will be dependent on the integrator used to

ensure connection to the master BMS system.

Data point name Meaning

Device Device

Diagnostic Diagnostics

SystemClock System time

AirQuality Air quality

RoomTmp Room temperature

RmUTmp1 HMI-SG1

RmUTmp2 HMI-SG2

ValidRoomTmp Temperature in the room aer control

ReturnAirTmp Outlet air temperature

SupplyTmp Inlet air temperature

OutTmp Outdoor temperature

HtgFrstTmp Return water temperature (water heater)

ExhaustTmp Outlet air temperature aer the heat exchanger

PreElHtgTmp Temperature, electric pre-heating

PreWtrHtgTmp Return water temperature (water pre-heating)

BrnrFlueTmp Flue gas temperature

RoomHum Air humidity in the room - relative

SupplyHum Inlet air humidity - relative

OutHum Outdoor air humidity - relative

RmHumAbs Absolute air humidity in the room

SplyHumAbs Absolute inlet air humidity

OutHumAbs Absolute outdoor air humidity

RmEnth e room - enthalpy

OutEnth Outdoor enthalpy

ActOpMode Current state of the device

ActFanStep Current state of the fans

OpModeAutoManSt.Swtch Manual mode (control)

OpModeAutoManStTmp.Swtch Manual mode (control)

Loading...

Loading...