4

Design

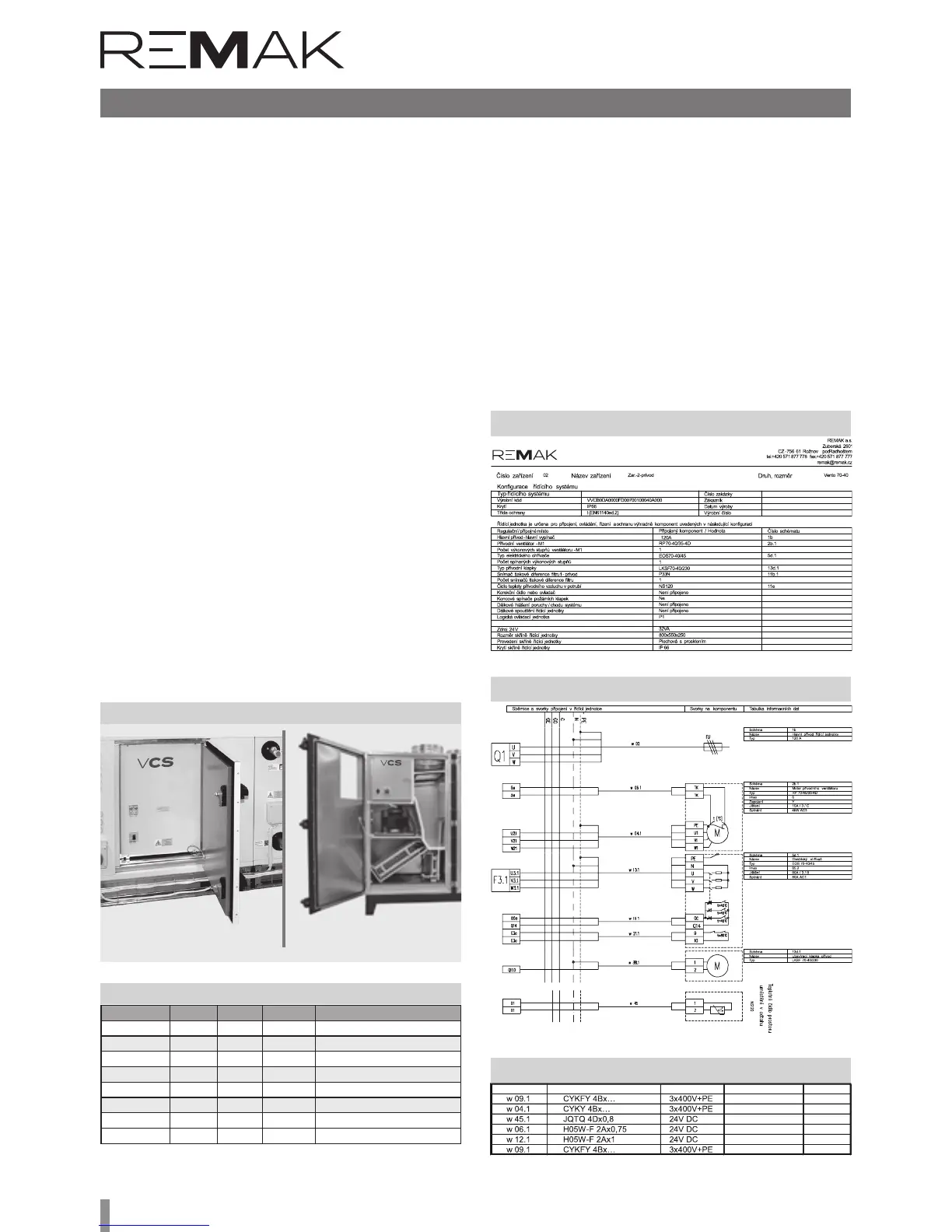

Table 2 – List of connecting cables (example)

Cable No.

Figure 7 – Component wiring (example)

Figure 6 – Summary of connected components (example)

Boxes

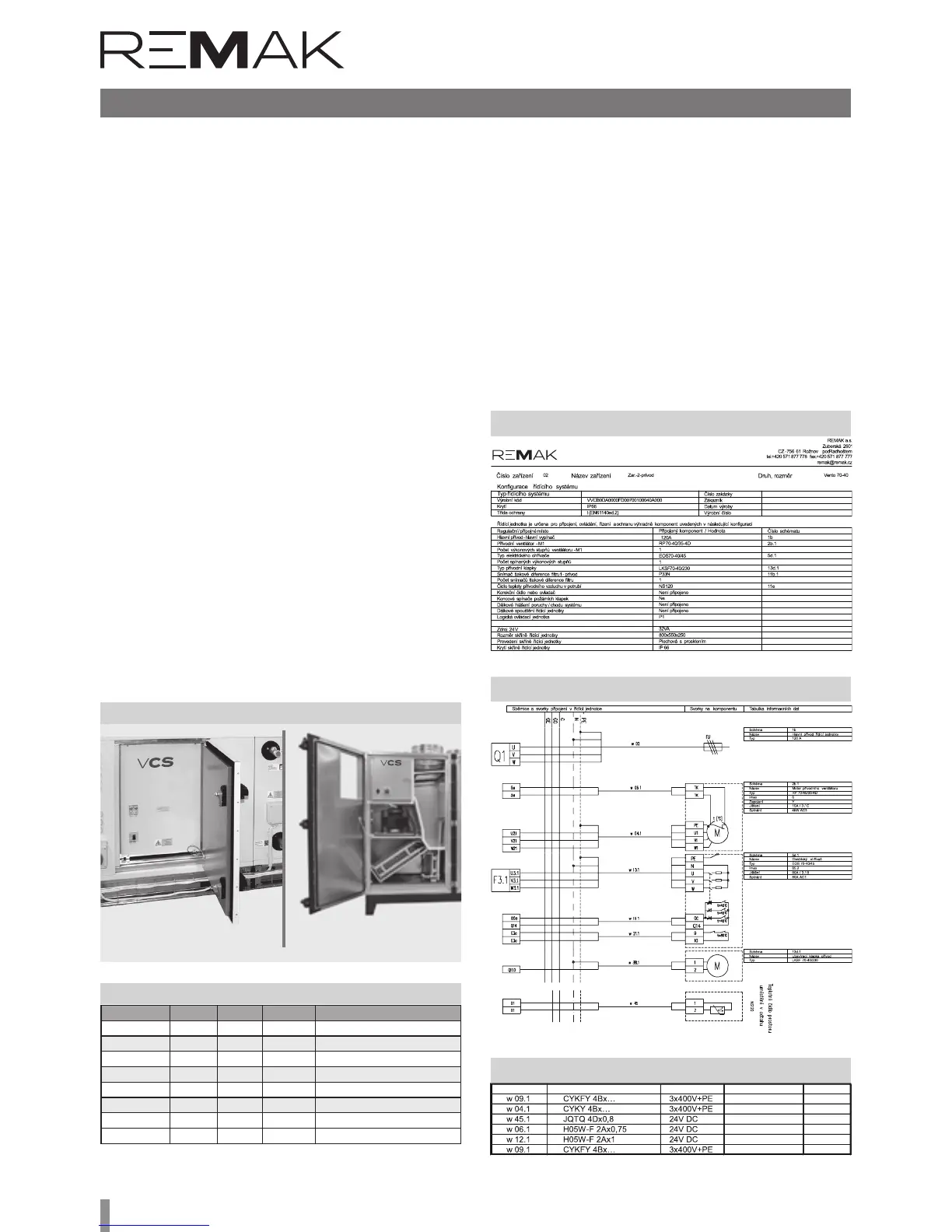

Indoor VCS control units are built into plastic or sheet metal

cabinets with front transparent doors under which controls

are located. e permissible ambient temperature is 0 ° C

to + 40 ° C.

VCS in exterior design are built into sheet metal cabinets

with full front doors under which controls are located. In

the confi guration so ware we can design: range of average

temperatures -40 ° C to 35 ° C, cabinet mounting (hanging /

stand), door design (le / right), lighting, service drawer (select

according to customer's destination).

A space of minimum 15 cm must be le on each side of the

box to allow access for cooling air and for changing the fi lter

which is fi tted in front of the fan.

As a standard, we provide a door lock and a box for storing

unit documents. Depending on the particular confi guration of

the control unit, these enclosure dimensions are used (Table

1). e electrical enclosure of the plastic case corresponds to

IP 65 with the door closed and IP 40 when the door is open.

e electrical cabinet cover is IP 55 or IP 66 (depending on

enclosure type) when the door is closed and IP 20 when the

door is open. e metal enclosure with additional ventilation

is IP54 with the door closed and IP 20 with the door open.

The VCS control units can be mounted directly on the

Flammability Levels A and B according to EN 13501-1.

Additionally, the VCS control unit can be manufactured in an

integrated design as part of the ventilation unit section. One

of the options is a built-in section for assembled VZTs, which

includes adjustments for the environment. is section is used

when designing VZT with IP44 protection as well

for outdoor units (with heating or cooling of the control unit).

Table 1 – box dimensions in mm

If needed, the boxes, sized 2000 × 800 × 400 mm and 2000 × 1000 × 400 mm, can be

fi tted with a ventilation set – a fan and a louver in opposite corners.

VCS

ACX36/RMK

Figure 5 – Installation in the XP unit section

Design

e control system design is based on the selection of re-

quired features and on its internal confi guration. e design

is performed automatically using the algorithm integrated

into the design so ware also used for the air-handling unit

design. e design output provides an exact specifi cation of

the control unit, including the following individualised lists for

a specifi c device:

n Summary of connected components

n Wiring diagrams of all components

n List of all recommended cables for the connection of all

components (the cables must always be used in accord-

ance with the electrical equipment project documenta-

tion).

Version Height Width Depth Usual application

Plastic 610 340 160

Vento, FP, some XP (single-speed)

Plastic 610 448 160

Vento, FP, some XP (single-speed)

Plastic 842 448 160

Vento, FP, some XP (single-speed)

Sheet-steel 800 550 250 XP, sophisticated Vento assemblies

Sheet-steel 1200 750 300 XP

Sheet-steel 1600 750 300 XP

Sheet-steel 2000 800 400 XP

Sheet-steel 2000 1000 400 XP

(Recommended) cable type Power Supply Cable length Note

a) AeroMaster XP b) CAKE

Loading...

Loading...