repligen.com IF.UG.028 R1

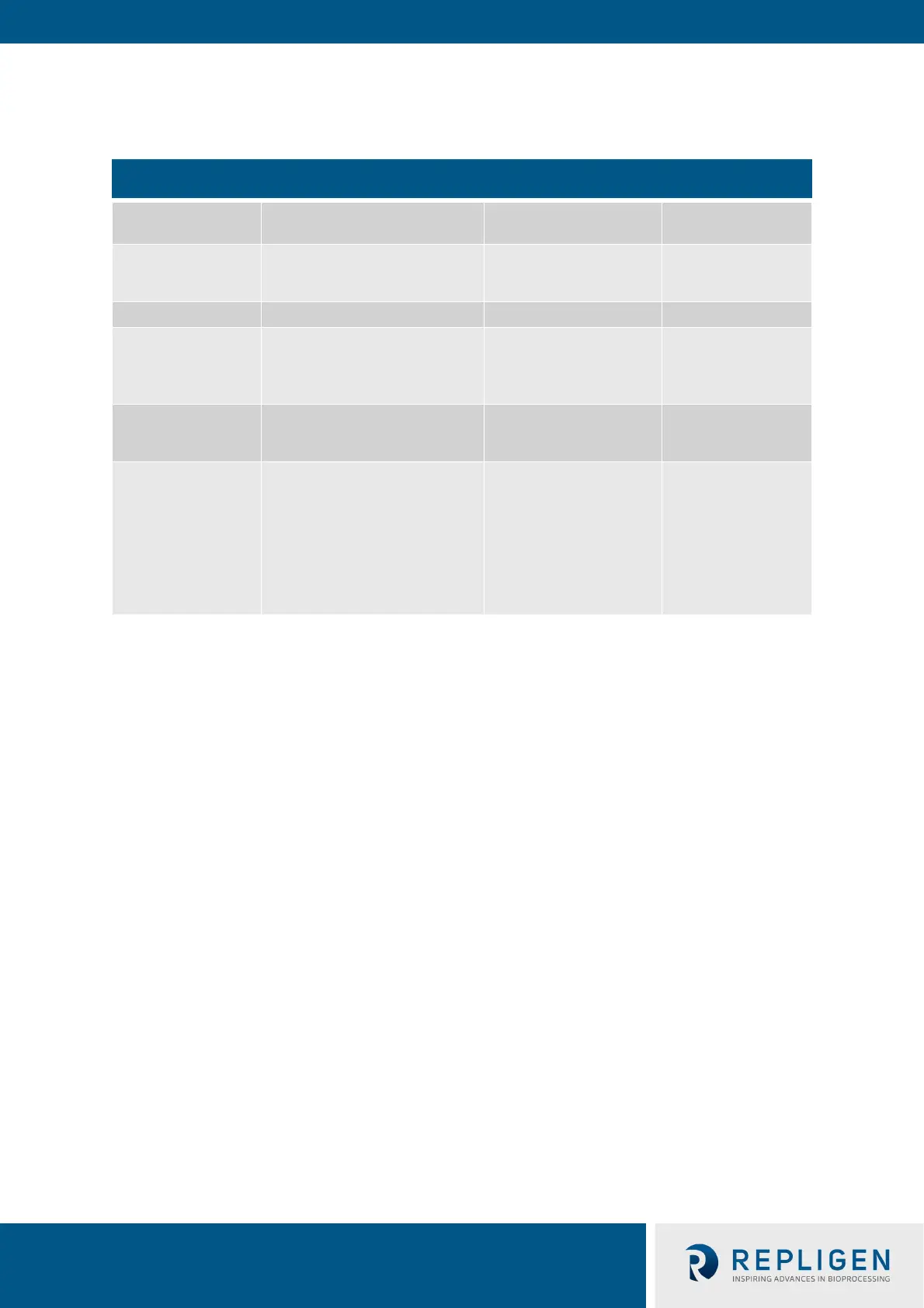

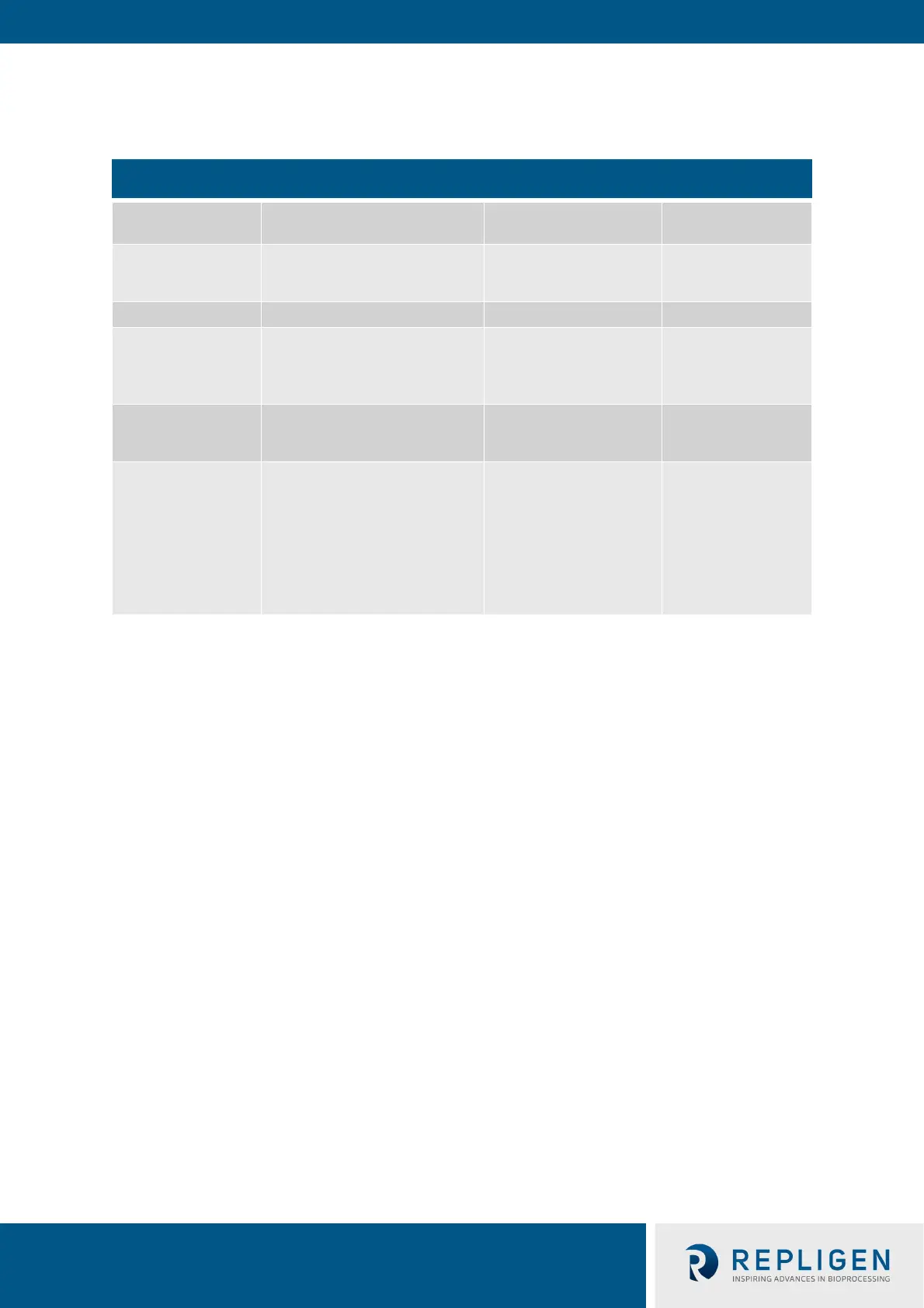

4. System specifications

Table 3. KrosFlo® Systems specifications

5. Major components

The major components used in KrosFlo® Systems are:

• Retentate (recirculating) Pump (P-01) - Levitronix LPM-600.3 - 10 low-shear centrifugal

pump

• Product pump (P-02) - MasterFlex® 77420-10 I/P peristaltic pump

• Buffer Pump (P-03) - MasterFlex® 77420-10 I/P peristaltic pump

• Retentate flowmeter - Sonotec® FS04.210 C0.55/230 V2.0

• Permeate flowmeter - Levitronix LFS-06SU / LFS-10SU

• Reactor scale input - 4 - 20 mA

• Pressure sensors - Repligen disposable pressure transducers

• Controller - Allen-Bradley PLC (Programmable Logic Controller)

• HMI - Allen-Bradley Integrated Panel Display Computer (Human-Machine Interface)

• ProConnex® Flow Path - Designed flexible tube flow path from Repligen

• Support structure - Stainless steel filter stand and lab cart from Repligen

135 Kg

225 Kg

(L x W x H)

81 x 61 x 133 cm

120 x 61 x 203 cm

P-01 100 - 9000 RPM

P-02 0.1 - 650 RPM

15” LCD touchscreen

and HMI – IP66

0 - 40° C

Frame and electrical cabinet:

Stainless Steel-304

Stainless Steel-304 and

Polyurethane

path components:

Polypropylene,

polycarbonate,

Polysulfone, and

C-Flex®/

Pharmapure®

Loading...

Loading...