Technical Bulletin PAGE: 7/8

Model: Vacuum Feed LCIT RT5100

3. Check for the following, which indicate a higher risk of the wire breaking.

See Page 3 above for details.

1) Presence of scraped powder generated by bottom plate sliding

2) Less smooth up-and-down movement of the bottom plate.

3) Adjust the tray dimensions if either the span or clearance at EITHER of the two

positions is less than the target (See Page 6).

Important: Do not adjust the span or clearance beyond the target dimensions.

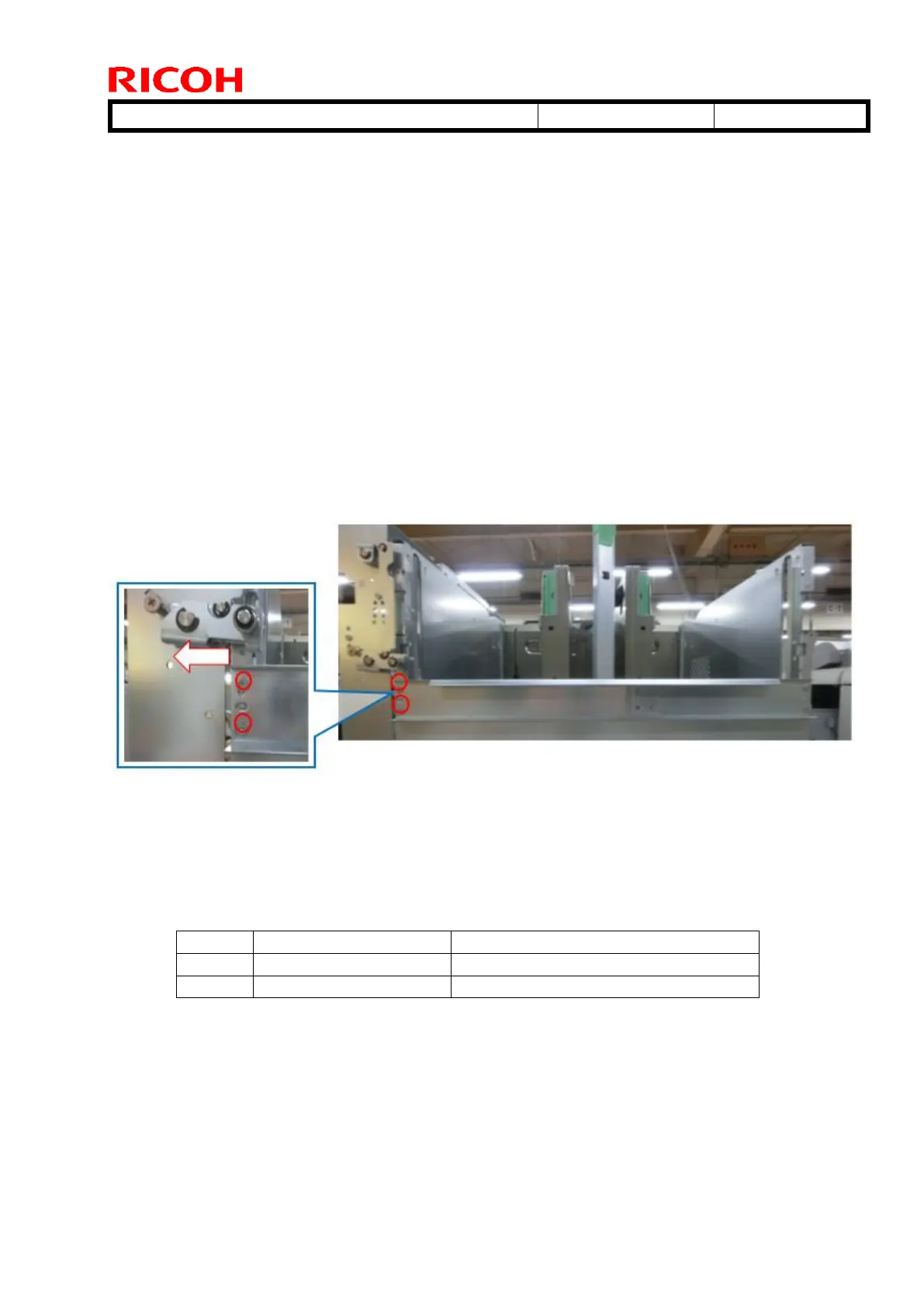

Procedure (Fig. 12):

a. Loosen the 2 screws circled in red on the right side of the tray plate

b. Shift the front & rear side plates in the direction of the white arrow as far as they will

go, until each screw touches the inner edge of the screw hole.

c. Tighten the 2 screws.

Fig. 12

Replace the side plate as shown in Table 1 below if the span is not adjustable to within the

target dimension and the cut-off portion is deformed.

Table 1

Side Plate: Tray: Front: Peen

Side Plate: Tray: Rear: Peen

Loading...

Loading...