6.Troubleshooting

196

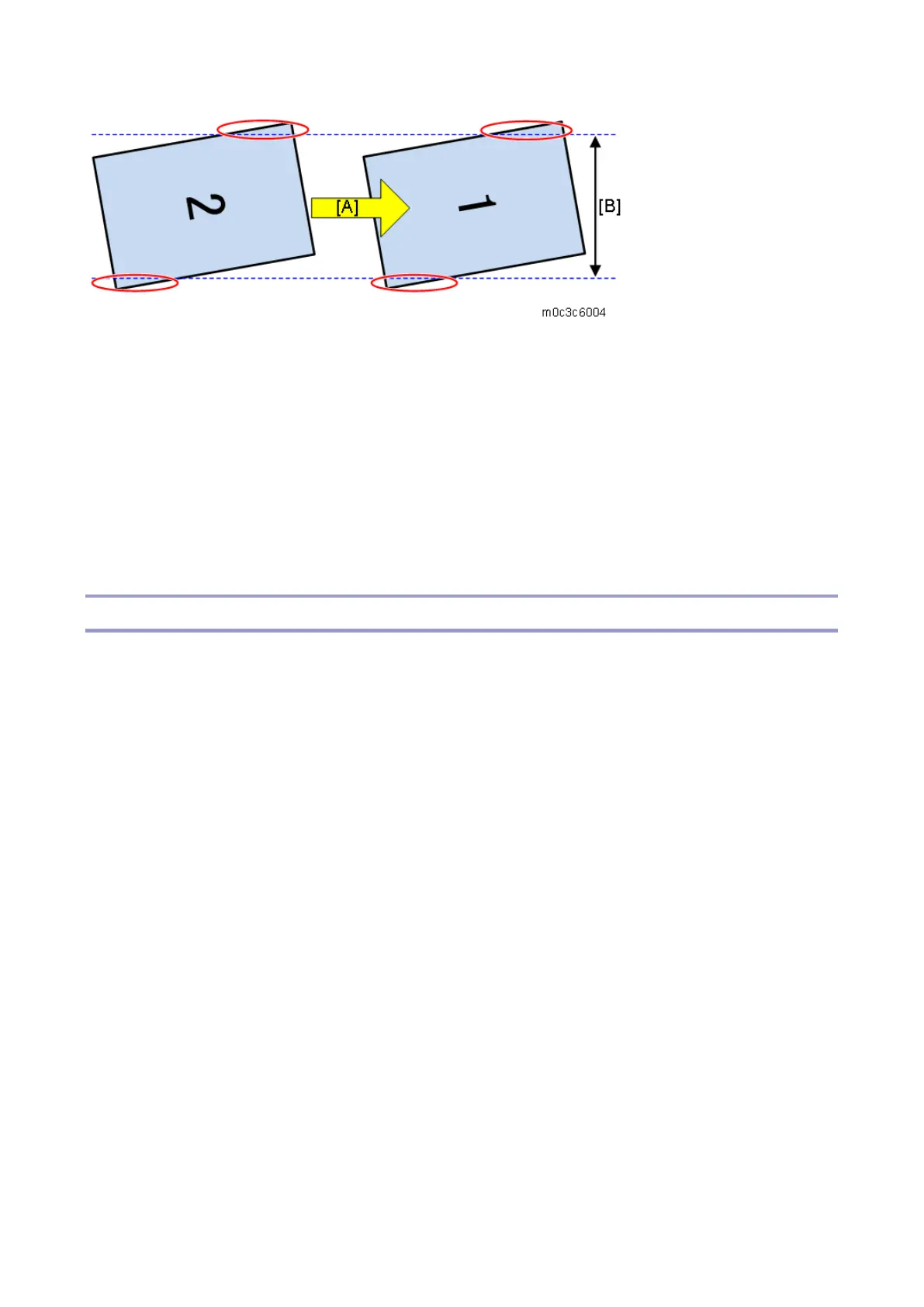

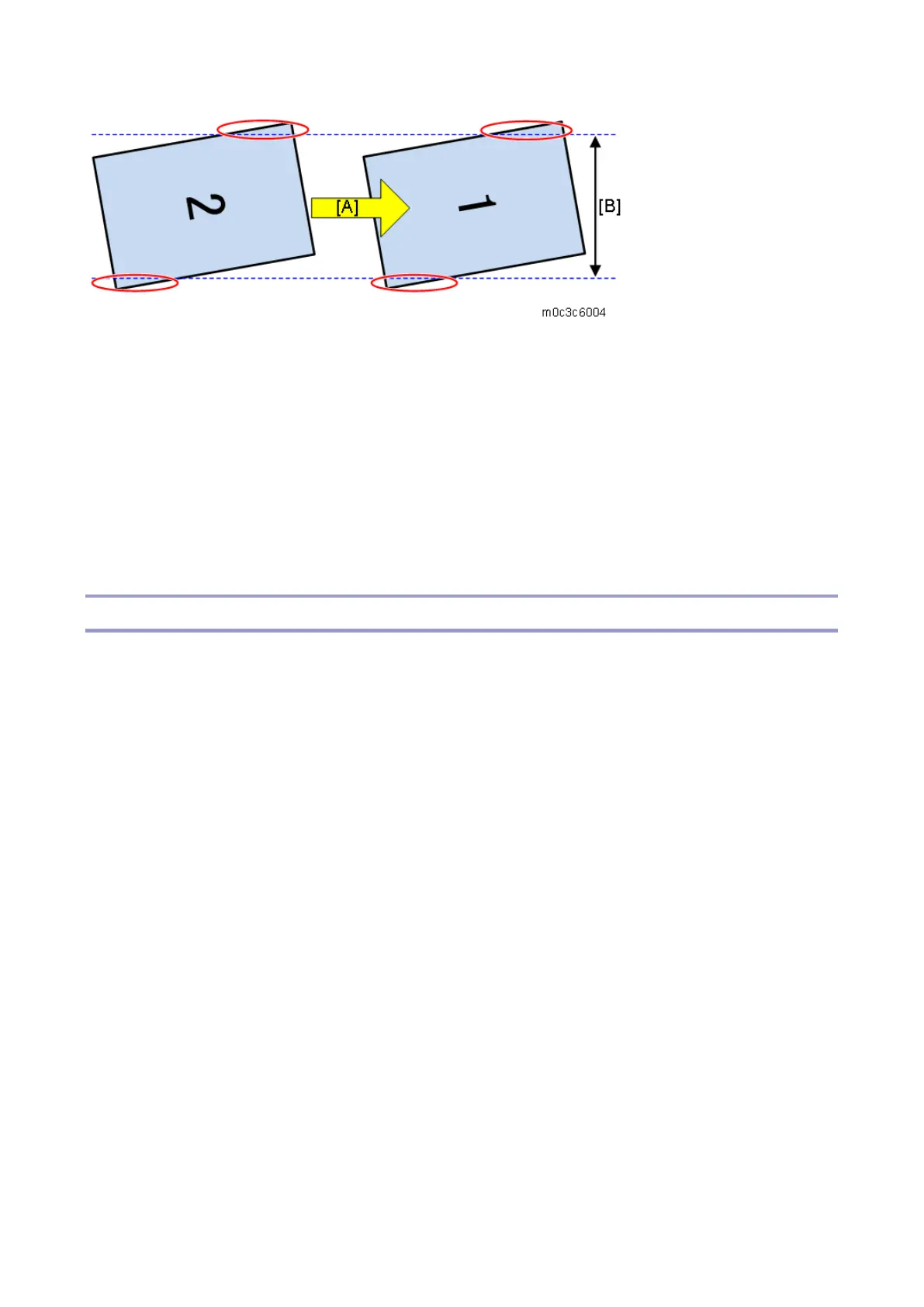

[A]: Paper feed direction

[B]: Image area of the drum

Solution

When there are gaps between the paper and the side or the end fences of the paper tray, adjust the

side or the end fences of the paper tray to remove the gaps.

If the problem still exists, set [Interval Setting] of SP. Refer to "Recycled or Thin Paper Is Severely

Curled after Printing".

Poor Printing (Offset)

Problem

Poor printing (offset) may occur.

Causes

The fusing temperature is too high for some paper types.

Solutions

When poor printing occurs with the same paper types, change the settings of the fusing temperatures of

the paper type in the following SPs.

When occurring with Plain/Thin paper: Set the fusing temperature 5 degrees lower.

Four-line LCD panel: SP menu > [Engine Maintenance] > [Fusing Unit Temperature] > [Plain

paper]/[Thin Paper]s

Touch panel: SP menu > [Engine Service Setting] > [Fusing Unit Temperature] > [Plain paper]/[Thin

Paper]

When occurring with Thick 1 paper: Set the fusing temperature 5 to 10 degrees lower and make

sure that toner has fused sufficiently on the printed paper.

Four-line LCD panel: SP menu > [Engine Maintenance] > [Fusing Unit Temperature] > [Thick1 Paper]

Touch panel: SP menu > [Engine Service Setting] > [Fusing Unit Temperature] > [Thick1 Paper]

When offset occurs with a specific paper type, change the target paper type (without changing the

Loading...

Loading...