21

INSTALLATION

2

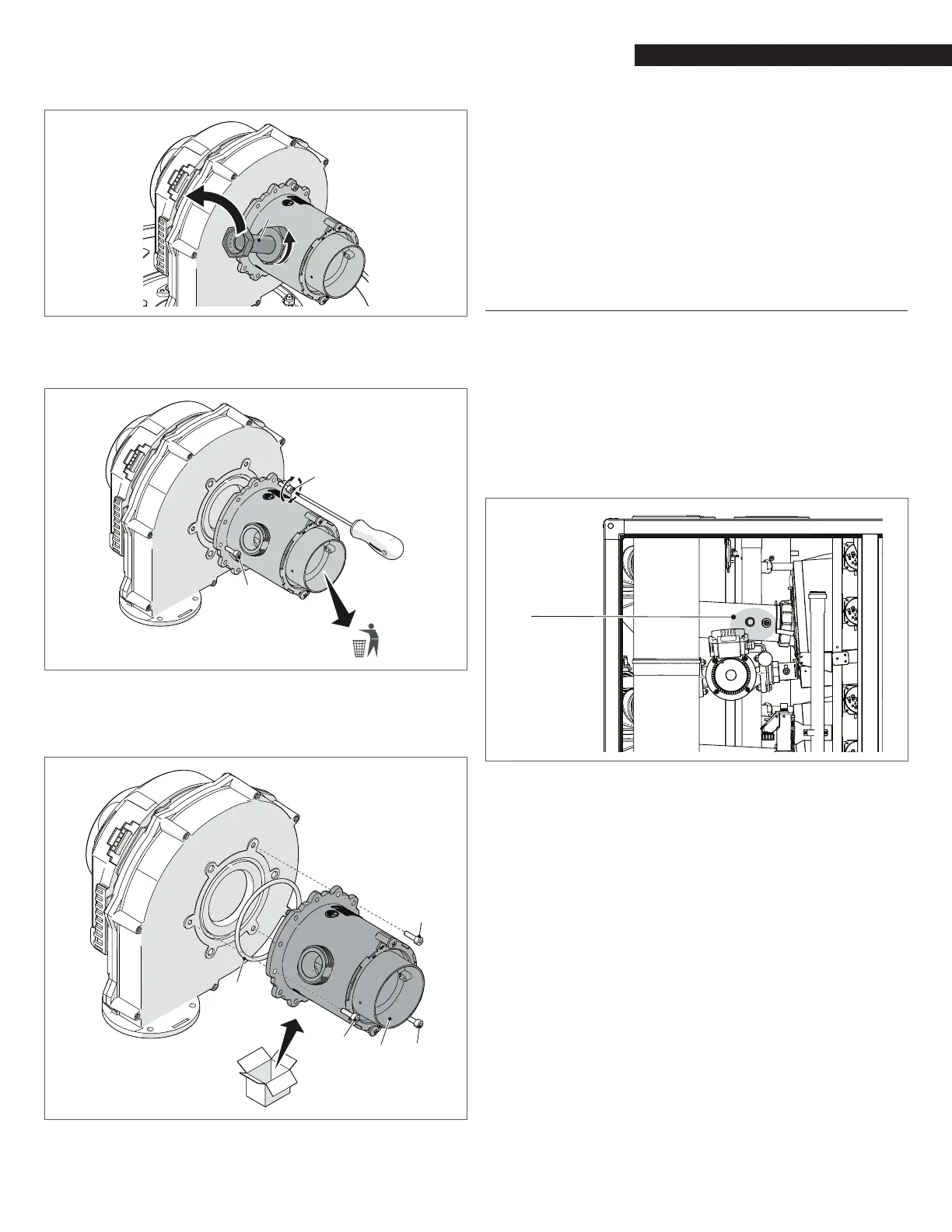

Fig. 15

NG mixer removal

− remove screws (3) in order to get out the mixer

3

3

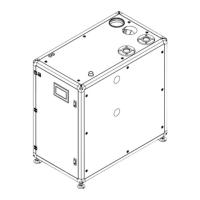

Fig. 16

NG mixer removal

− connect the LPG mixer (4) to the fan, putting in the O-ring

(5) and screws (6)

4

5

6

6

Fig. 17

LPG mixer installation

− reassemble the fan unit and the mixer by reversing the

previous operations.

− Use the PB inner display to enter the appliance conguration

menu and change the parameter #98 from ‘’80‘’ to

‘’81‘’. Follow this path: menu-> setting ->

appliance

->

conguration -> password -> boiler -> managing -> 98

appliance

setting (from ‘’80‘’ to ‘’81‘’) -> conguration

conrmed (‘’yes’’). Repeat the same sequence for each

dependent module.

− Adjust the O2 parameter as explained in next chapter

− Afx the gas type label from the gas conversion kit to the

appliance.

− Repeat above process for all heat exchangers.

4.12.5 Adjusting and Setting O2 Limits

− Insert a combustion analyzer probe into the test port

shown in Fig. 18;

− Go to the Touchscreen and access the Module screen (as

described on “6.3.4 Module Screen” page 35) relevant to

the module under analysis;

− Press “MODULE TEST” button;

− Press “HIGH POWER” button.

Wait 2 or 3 minutes to reach steady state conditions and record

the O

2 value.

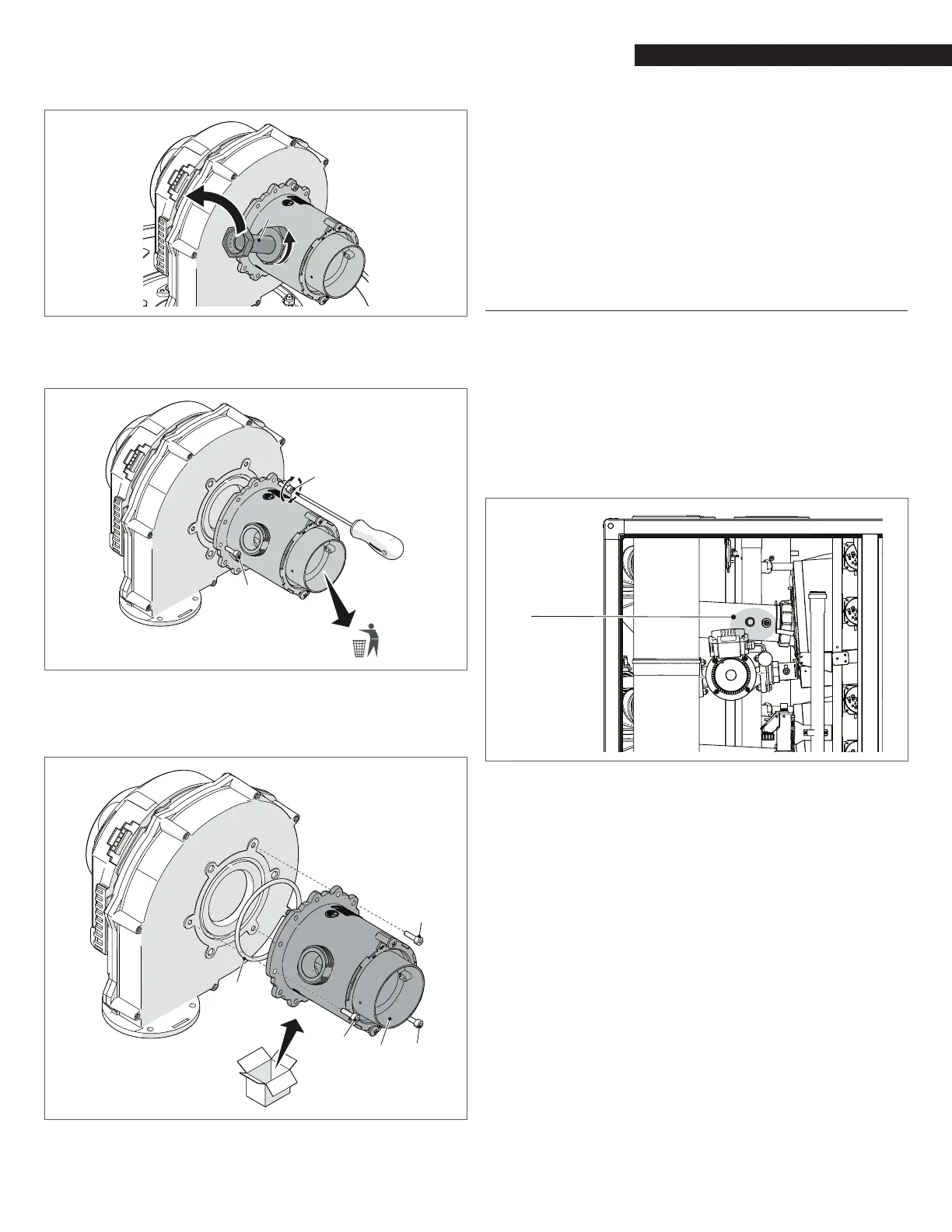

Test port of

the module

Fig. 18

Test Port for Combustion Analysis (available on each

individual heat exchanger)

To adjust the O2 value at high-re turn the screw “A” (rotate

counter-clockwise to decrease O

2) shown in Fig. 19. An allen type

wrench is necessary for this adjustment.

Verify that the value of O

2 is stable and within the range indicated in

the following table (be careful to make small changes and conrm

that the value is stable before making additional adjustment).

Loading...

Loading...