49

SHUTDOWN

49

APPENDIX

APPENDIX

Error no. Error Description Checks Solutions

24 FLUE_SWITCH_NOT_CLOSING The blocked ue sensor is not closed

within 10 minutes

25 TSUPPLY_DIFF_ERROR The 2 supply sensors deviate too much for

more than 60 seconds

26 TFLUE_DIFF_ERROR The 2 ue sensors deviate too much for

more than 60 seconds

27 FILLING_TOO_MUCH Too many automated lling attempts in a

short time period

28 FILL_TIME_ERROR Filling takes too long

29 PSM_ERROR Internal software error

30 REGISTER_ERROR Internal software error Control board replacement

31 T_EXCHANGE_LOCK_ERROR Exchange temperature exceeded the

maximum temperature

32 T_EXCHANGE_DIFF_ERROR The 2 exchange sensors deviate too much

for more than 60 seconds

33 LWCO_1_ERROR Low Water Cut Off 1 error Check the LWCO a- Verify water is in the boiler.

b- Verify good connection between

co

ntrol module and low water probe.

34 LWCO_2_ERROR Low Water Cut Off 2 error a- Check to ensure all valves are

open, pump is running.

b- Check the wiring between the

controller and the LWCO probe.

a- Verify water is in the boiler.

b- Verify good connection between

co

ntrol module and low water probe.

35 GAS_PRESSURE_ERROR Flue pressure switch is closed a- Check gas pressure to ensure

it is steady and within the

recommended range for the unit.

b- Check with as many modules

on as possible to ensure supply

connections are sized properly.

36 AIR_DAMPER_LOCKING Air Damper feedback is not received

when the relative output is open for the

fourth time.

37 FLUE_PRESSURE_LOCKING Flue pressure switch is closed for the

fourth time.

a- Check for obstruction in the

ue piping.

b- Blocking errors should be

recorded prior to the occurrence of

this Locking error.

c- Check for condensate in the

hose connecting the ue pressure

switch to ensure it isn’t blocked.

BLOCKING ERRORS

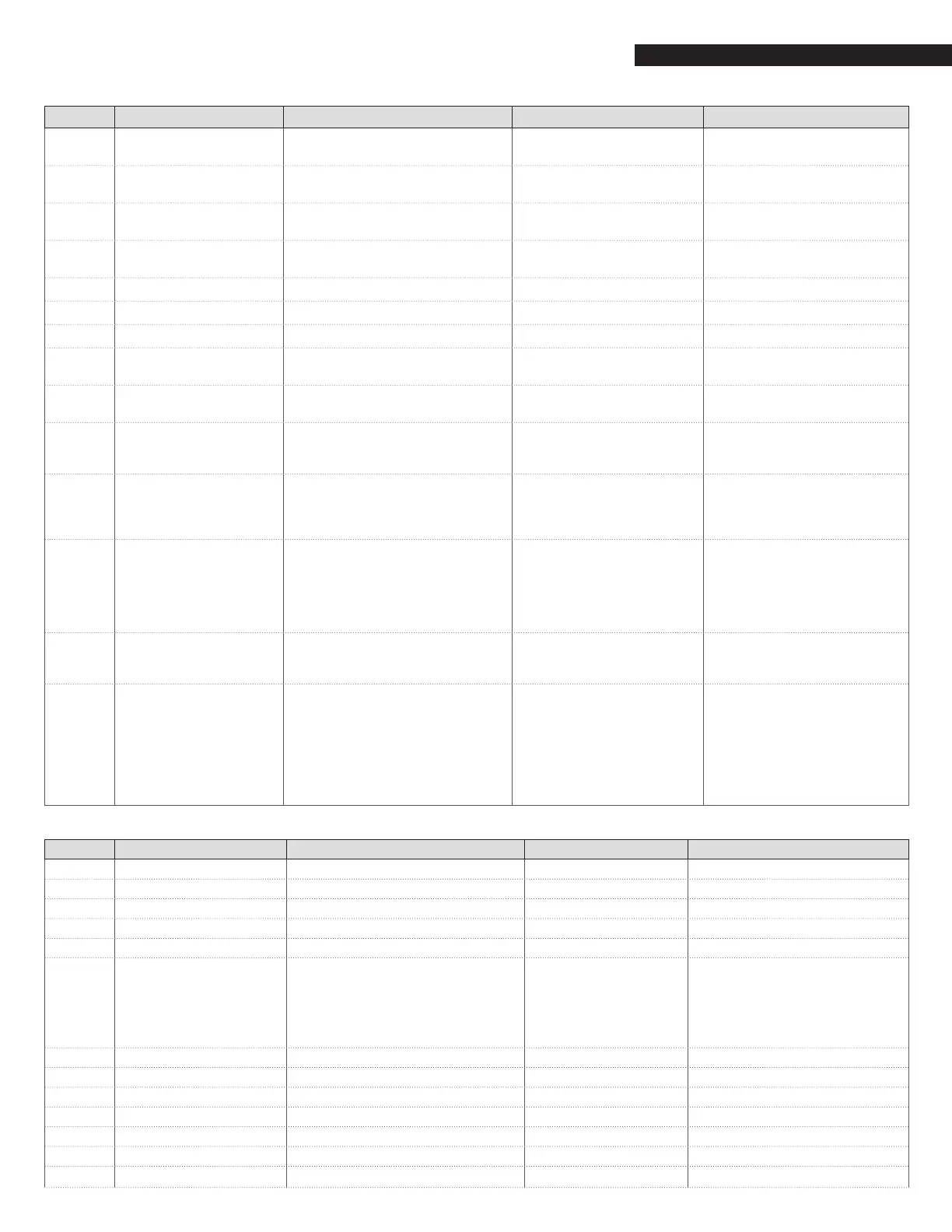

Error no. Error Description Checks Solutions

100 WD_ERROR_RAM Internal software error

Control board replacement

101 WD_ERROR_ROM Internal software error

Control board replacement

102 WD_ERROR_STACK Internal software error

Control board replacement

103 WD_ERROR_REGISTER Internal software error

Control board replacement

104 WD_ERROR_XRL Internal software error

Control board replacement

105 HIGH_TEMP_ERROR

Supply temperature exceeds 110°C (230°F)

with gas valve closed

a- Check the pump to verify

the ow circulation;

b- Check if the valves on

hydraulic circuit are open;

c- Check the supply

temperature sensor.

a- Change the pump or restart it;

b- Open the valves on hydraulic circuit;

c- Verify that the temperature sensor

has the correct resistance values. If

values are incorrect sensor must be

replaced.

106 REFHI_TOO_HIGH Internal software error

Control board replacement

107 REFHI_TOO_LOW Internal software error

Control board replacement

108 REFLO_TOO_HIGH Internal software error

Control board replacement

109 REFLO_TOO_LOW Internal software error

Control board replacement

110 REFHI2_TOO_HIGH Internal software error

Control board replacement

111 REFHI2_TOO_LOW Internal software error

Control board replacement

112 REFLO2_TOO_HIGH Internal software error

Control board replacement

Loading...

Loading...