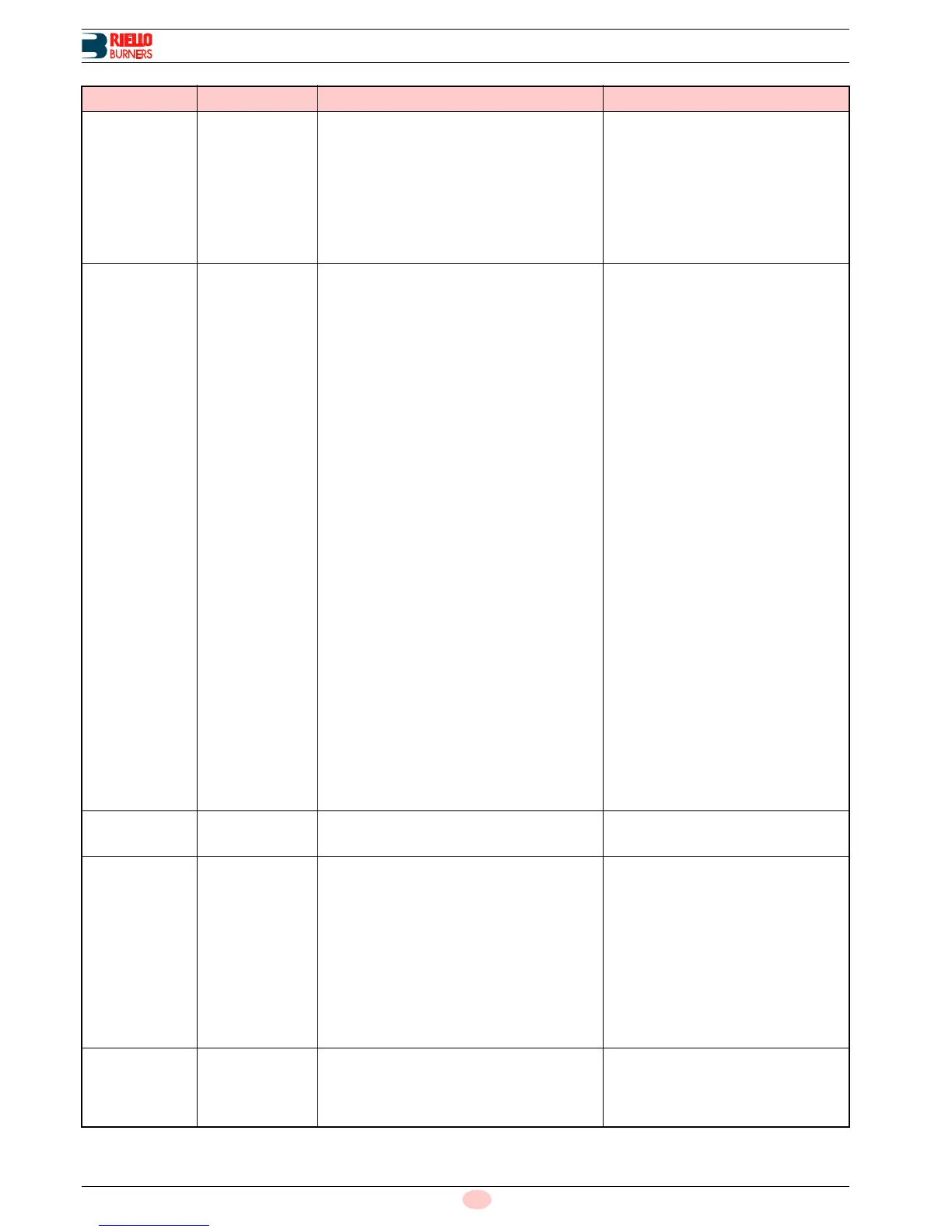

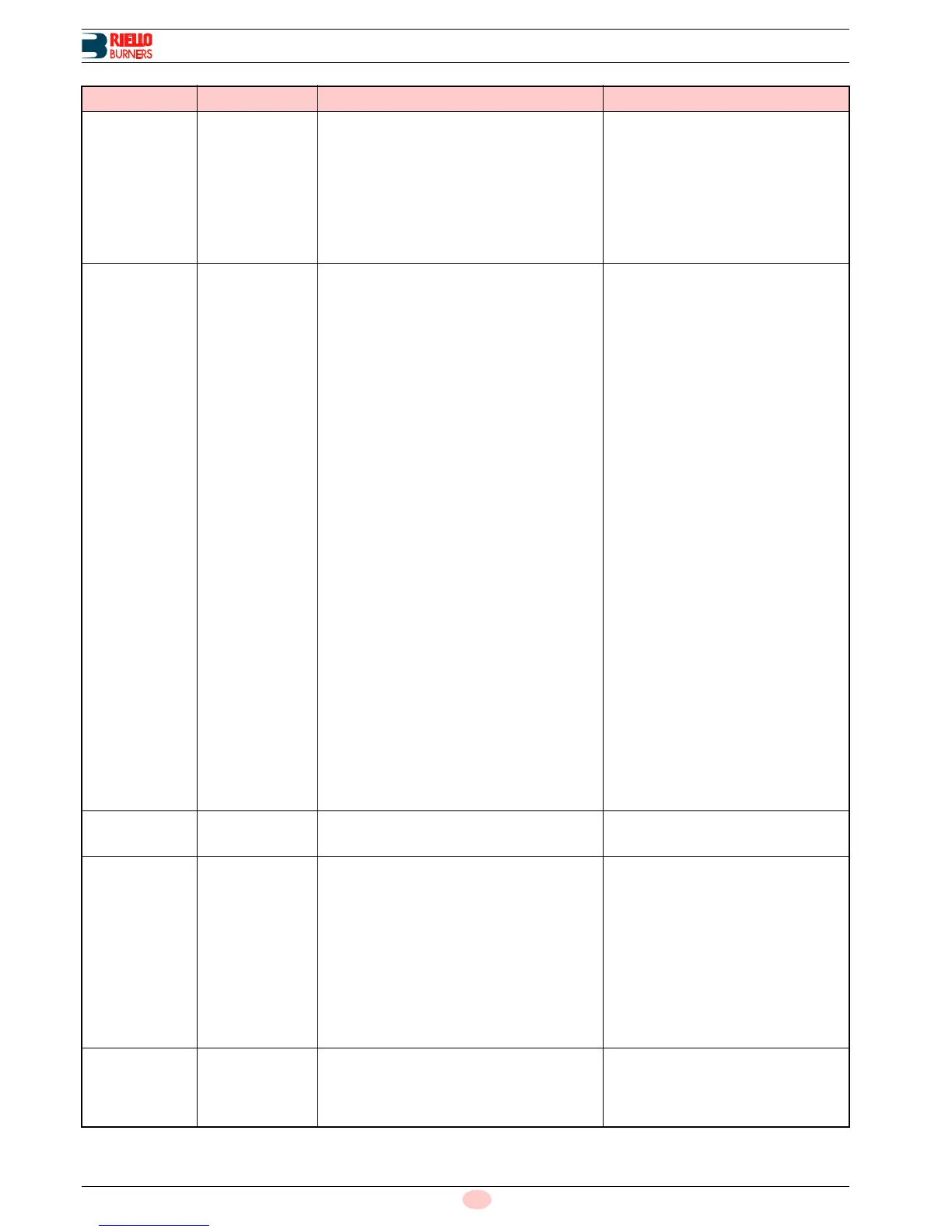

Maintenance

SIGNAL FAULT POSSIBLE CAUSE SOLUTION

No blink The burner does

not start

1 - No electrical power supply . . . . . . . . . . . . . Close all switches - Check fuses

2 - A limit or safety control device is open. . . . Adjust or replace

3 - Control box lock-out . . . . . . . . . . . . . . . . . . Reset control box (no sooner than 10 s

after the lockout)

4 - Pump is jammed . . . . . . . . . . . . . . . . . . . . Replace

5 - Erroneous electrical connections . . . . . . . . Check connections

6 - Defective control box . . . . . . . . . . . . . . . . . Replace

7 - Defective electrical motor. . . . . . . . . . . . . . Replace

2 pulses

After pre-purge and

the safety time, the

burner goes to

lockout at the end

of the safety time

8 - No fuel in tank; water on tank bottom. . . . . Top up fuel level or suck up water

9 - Inappropriate head and air damper adjust-

ments

Adjust, see page 17 and page 23

10 - Fuel solenoid valves fail to open (1st stage

or safety)

Check connections; replace coil

11 - 1st nozzle clogged, dirty, or deformed . . . . Replace

12 - Dirty or poorly adjusted firing electrodes . . Adjust or clean

13 - Grounded electrode due to broken insula-

tion

Replace

14 - High voltage cable defective or grounded . Replace

15 - High voltage cable deformed by high tem-

perature

Replace and protect

16 - Ignition transformer defective. . . . . . . . . . . Replace

17 - Erroneous valves or transformer electrical

connections

Check

18 - Control box defective . . . . . . . . . . . . . . . . . Replace

19 - Pump unprimed . . . . . . . . . . . . . . . . . . . . . Prime pump and see “Pump unprimes”

20 - Pump/motor coupling broken . . . . . . . . . . . Replace

21 - Pump suction line connected to return line Correct connection

22 - Valves up-line from pump closed . . . . . . . . Open

23 - Filters dirty: line - pump - nozzle . . . . . . . . Clean

24 - Defective photocell or control box . . . . . . . Replace photocell or control box

25 - Photocell dirty. . . . . . . . . . . . . . . . . . . . . . . Clean

26 - 1st stage operation of cylinder is faulty . . . Change the cylinder

27 - Motor protection tripped . . . . . . . . . . . . . . . Reset thermal relay

28 - Defective motor command remote control

device

Substitute it

29 - Missing phase thermal cut-out trips . . . . . . Reset thermal cut-out when third phase

is re-connected

30 - Incorrect motor rotation direction . . . . . . . . Change motor electrical connections

4 pulses

The burner starts

and then goes into

lockout

31 - Photocell short-circuit. . . . . . . . . . . . . . . . . Replace photocell

32 - Light is entering or flame is simulated . . . . Eliminate light or replace control box

7 pulses

Flame detachment 33 - Poorly adjusted head . . . . . . . . . . . . . . . . . Adjust, see page 17,

34 - Poorly adjusted or dirty firing electrodes . . Adjust, see Fig. 12 on page 17

35 - Poorly adjusted fan air gate: too much air . Adjust

36 - 1st nozzle is too big (pulsation) . . . . . . . . . Reduce 1st nozzle delivery

37 - 1st nozzle is too small (flame detachment) Increase 1st nozzle delivery

38 - 1st nozzle dirty, or deformed . . . . . . . . . . . Replace

39 - Inappropriate pump pressure Adjust to between 10 and 14 bar

40 - 1st stage nozzle unsuited to burner or boiler See Nozzle Table, page 16; reduce 1st

stage nozzle

41 - Defective 1st stage nozzle . . . . . . . . . . . . . Replace

The burner does

not pass to 2nd

stage

42 - Control device TR does not close . . . . . . . Adjust or replace

43 - Defective control box . . . . . . . . . . . . . . . . . Replace

44 - 2nd stage sol. valve coil defective . . . . . . . Replace

45 - Piston jammed in valve unit . . . . . . . . . . . . Replace entire unit

Loading...

Loading...