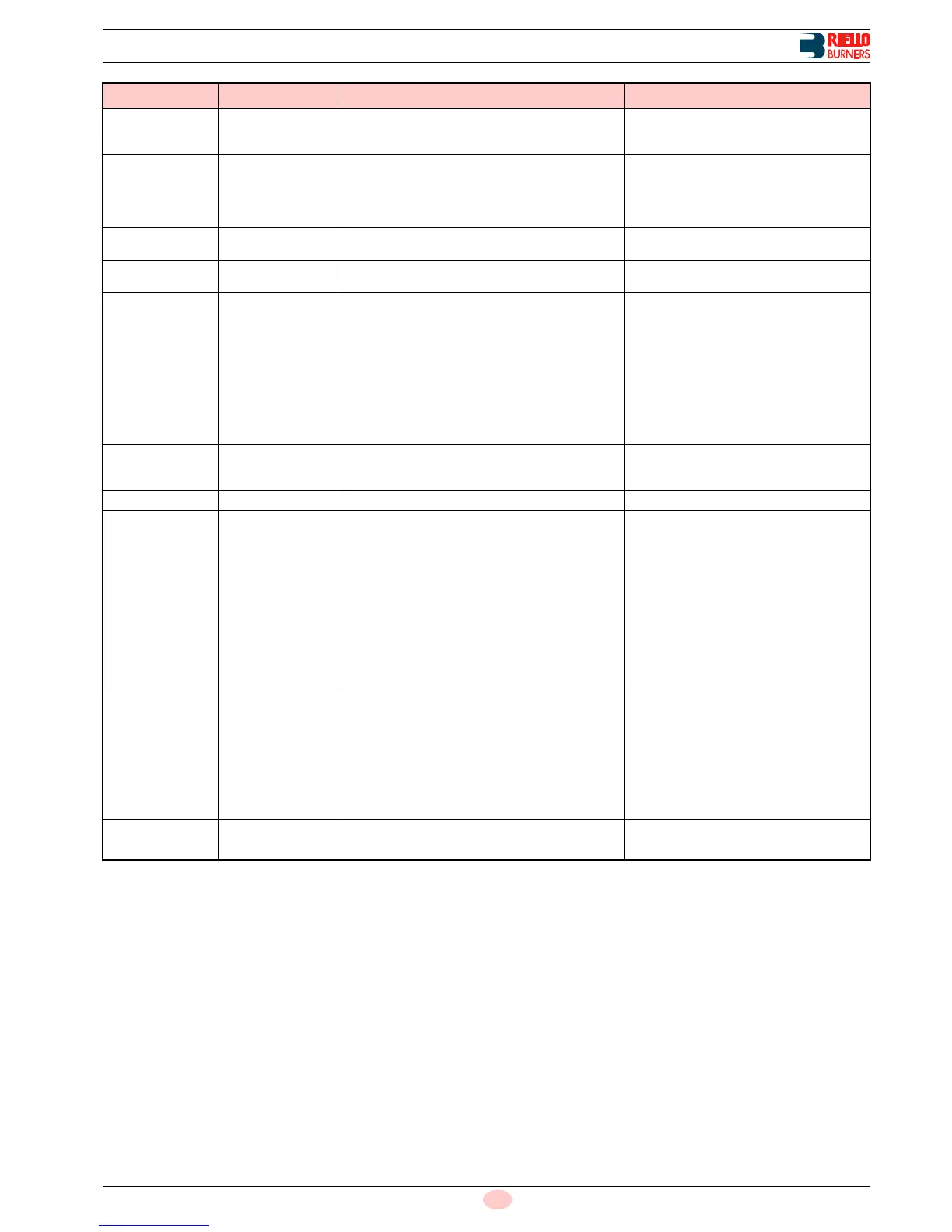

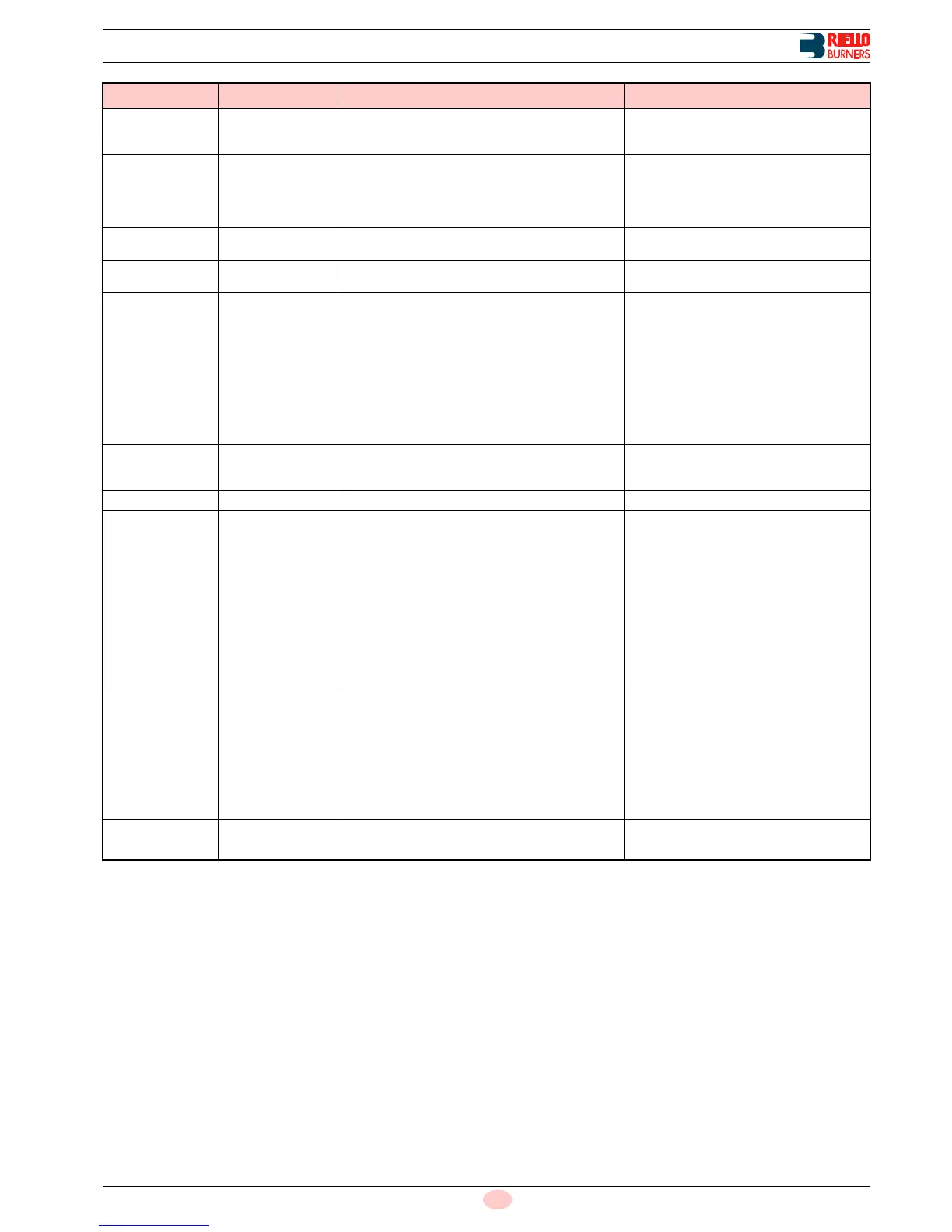

Maintenance

Fuel passes to 2nd

stage but air

remains in 1st

46 - Low pump pressure . . . . . . . . . . . . . . . . . . Increase

47 - 2nd stage operation of cylinder is faulty . . . Change cylinder

Burner stops at

transition between

1st and 2nd stage.

Burner repeats

starting cycle.

48 - Nozzle dirty. . . . . . . . . . . . . . . . . . . . . . . . . Renew nozzle

49 - Photocell dirty. . . . . . . . . . . . . . . . . . . . . . . Clean

50 - Excess air. . . . . . . . . . . . . . . . . . . . . . . . . . Reduce

Uneven fuel supply 51 - Check if cause is in pump or fuel supply . .

system

Feed burner from tank located near

burner

Internally rusted

pump

52 - Water in tank . . . . . . . . . . . . . . . . . . . . . . . Suck water from tank bottom with sepa-

rate pump

Noisy pump, unsta-

ble pressure

53 - Air has entered the suction line . . . . . . . . . Tighten connectors

- Depression value too high (higher than 35 cm

Hg):

54 - Tank/burner height difference too great . . . Feed burner with loop circuit

55 - Piping diameter too small . . . . . . . . . . . . . . Increase

56 - Suction filters clogged . . . . . . . . . . . . . . . . Clean

57 - Suction valves closed. . . . . . . . . . . . . . . . . Open

58 - Paraffin solidified due to low temperature . Add additive to fuel

Pump unprimes

after prolonged

pause

59 - Return pipe not immersed in fuel . . . . . . . . Bring to same height as suction pipe

60 - Air enters suction piping . . . . . . . . . . . . . . . Tighten connectors

Pump leaks fuel 61 - Leakage from sealing organ. . . . . . . . . . . . Replace pump

Smoke in flame

- dark Bacharach

- yellow Bacharach

62 - Not enough air . . . . . . . . . . . . . . . . . . . . . . Adjust head and fan gate, see page 17

and page 23

63 - Nozzle worn or dirty . . . . . . . . . . . . . . . . . . Replace

64 - Nozzle filter clogged . . . . . . . . . . . . . . . . . . Clean or replace

65 - Erroneous pump pressure . . . . . . . . . . . . . Adjust to between 10 - 14 bar

66 - Flame stability spirat dirty, loose, or

deformed

Clean, tighten in place, or replace

67 - Boiler room air vents insufficient . . . . . . . . Increase

68 - Too much air . . . . . . . . . . . . . . . . . . . . . . . Adjust head and fan gate, see page 17

and page 23

Dirty combustion

head

69 - Nozzle or filter dirty. . . . . . . . . . . . . . . . . . . Replace

70 - Unsuitable nozzle delivery or angle . . . . . . See recommended nozzles, page 16

71 - Loose nozzle . . . . . . . . . . . . . . . . . . . . . . . Tighten

72 - Impurities on flame stability spiral . . . . . . . Clean

73 - Erroneous head adjustment or not enough

air

Adjust, see page 17 and page 23; open

gate valve

74 - Blast tube length unsuited to boiler . . . . . . Contact boiler manufacturer

10 pulses

The burner goes to

lockout

75 - Connection or internal fault . . . . . . . . . . . .

76 - Presence of electromagnetic disturbance . Use the radio disturbance protection kit

SIGNAL FAULT POSSIBLE CAUSE SOLUTION

Loading...

Loading...