11

GENERAL

APPROVED CARBON MONOXIDE DETECTORS: Each carbon monoxide

detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certied.

SIGNAGE: A metal or plastic identication plate shall be perma-

nently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the ex-

haust vent terminal for the horizontally vented gas fueled heating

appliance or equipment.

The sign shall read, in print size no less than one-half (1/2) inch in

size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

INSPECTION: The state or local gas inspector of the side wall hor-

izontally vented gas fueled equipment shall not approve the in-

stallation unless, upon inspections, the inspector observes carbon

monoxide detectors and signage installed in accordance with the

provisions of 248 CRM 5.08(2)(a) 1 through 4.

b) EXEMPTIONS: The following equipment is exempt from 248 CRM

5.08(2)(a) 1 through 4:

− The equipment listed in Section 10 entitled “Equipment Not

Required To Be Vented” in the most current edition of NFPA

54 as adopted by the board;

− Product Approved side wall horizontally vented gas fueled

equipment installed in a room or structure separate from

the dwelling, building or structure used in whole or in part

for residential purposes.

c) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING SYS-

TEM REQUIRED: When the manufacturer of Product Approved side

wall horizontally mounted gas equipment provides a venting sys-

tem design or venting system components with the equipment,

the instructions provided by the manufacturer for the installation

of the equipment and venting shall include:

− Detailed instructions for the installation of the venting sys-

tem or the venting system components;

− A complete parts list for the venting system design or vent-

ing system.

d) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT VENTING SYS-

TEM NOT PROVIDED: When the manufacturer of Product Approved

side wall horizontally vented gas fueled equipment does not pro-

vide the parts for the venting of ue gases, but identies “special

venting systems”, the following requirements shall be satised by

the manufacturer:

− The referenced “special venting systems” shall be included

with the appliance or equipment installation instructions;

− The “special venting systems” shall be Product Approved by

the Board and the instructions for that system shall include

a parts list and detailed installation instructions.

e) A copy of all instructions for all Product Approved side wall hor-

izontally vented gas fueled equipment, all venting instructions, all

parts lists for venting instructions and/or venting design instruc-

tions shall remain with the appliance or equipment at the com-

pletion of the installation.

1.10 Suitable fuels

Permissible fuels

− Natural gas from the public gas supply in accordance with

national regulations with a total sulphur content < 15ppm.

− LP in accordance with national regulations with a content

of elementary sulphur < 1.5 ppm and volatile sulphur < 50

ppm.

− Ultra Low Sulphur Diesel in accordance with national regu-

lations with a content of elementary sulphur < 15 ppm (for

use as back-up fuel in condensing operation).

− Heating oil type 2 when boiler return temperature is not

lower than 140 °F; non-condensing operation. See the

warranty statement for additional details.

− A variety of alternate fuels such as biodiesel, jet fuel A, etc

may also be utilized. Contact

R for applicability.

9

Do not use gasoline, crankcase drainings, or any oil contain-

ing gasoline.

− The boiler must only be operated with the specied fuels.

− Only burners that are suitable for the specied fuels may

be used.

− Observe the manufacturer's burner selection list and the

burner manufacturer's instructions.

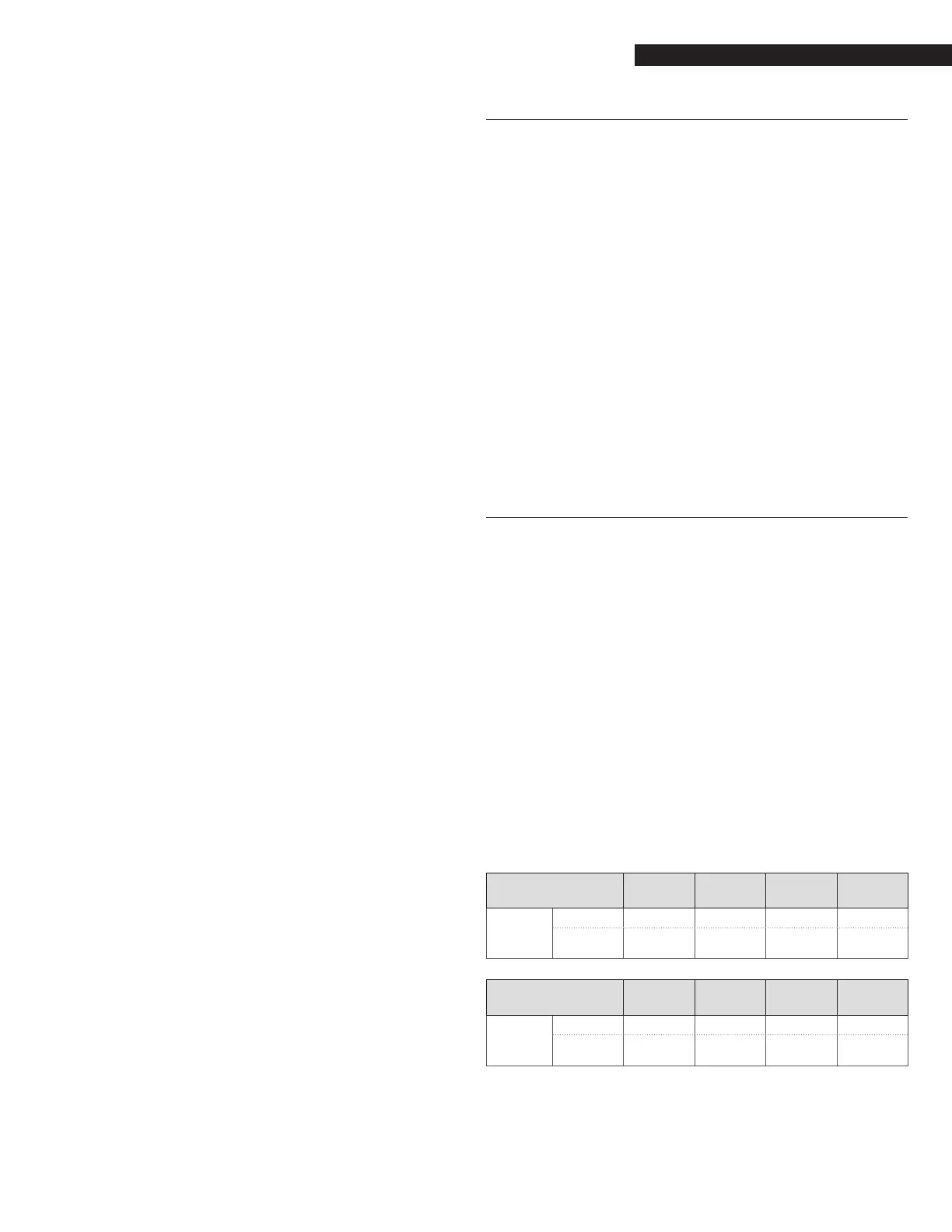

1.11 Burners

Follow the burner manufacturer’s instructions when tting the

burner. A pre-drilled burner plate is included with the boiler.

An adapter plate may be required if a non-standard burner is

used (see table).

As standard, the burner plate gasket must be trimmed in order to

t the burner blast tube.

The installer must cut the hole 3/8" larger than the blast tube di-

ameter.

The combustion chamber door must be opened to allow the

burner to be mounted.

If the burner head is too long to open/close the combustion

chamber door, the burner will have to be removed prior to the

opening/closing of the door.

For reduction of burner capacity according to altitude make refer-

ence to the burner manual.

9

After the burner is installed, ll the gap between the burner

tube and the refractory material in the door with the ceramic

insulation supplied loose with the boiler.

RTC 1000-

80

RTC 1300-

80

RTC 1700-

80

RTC 2300-

80

Fireside

pressure

drop

inch W.C. 1.284 1.846 2.007 2.208

mbar 3.2 4.6 5.0 5.5

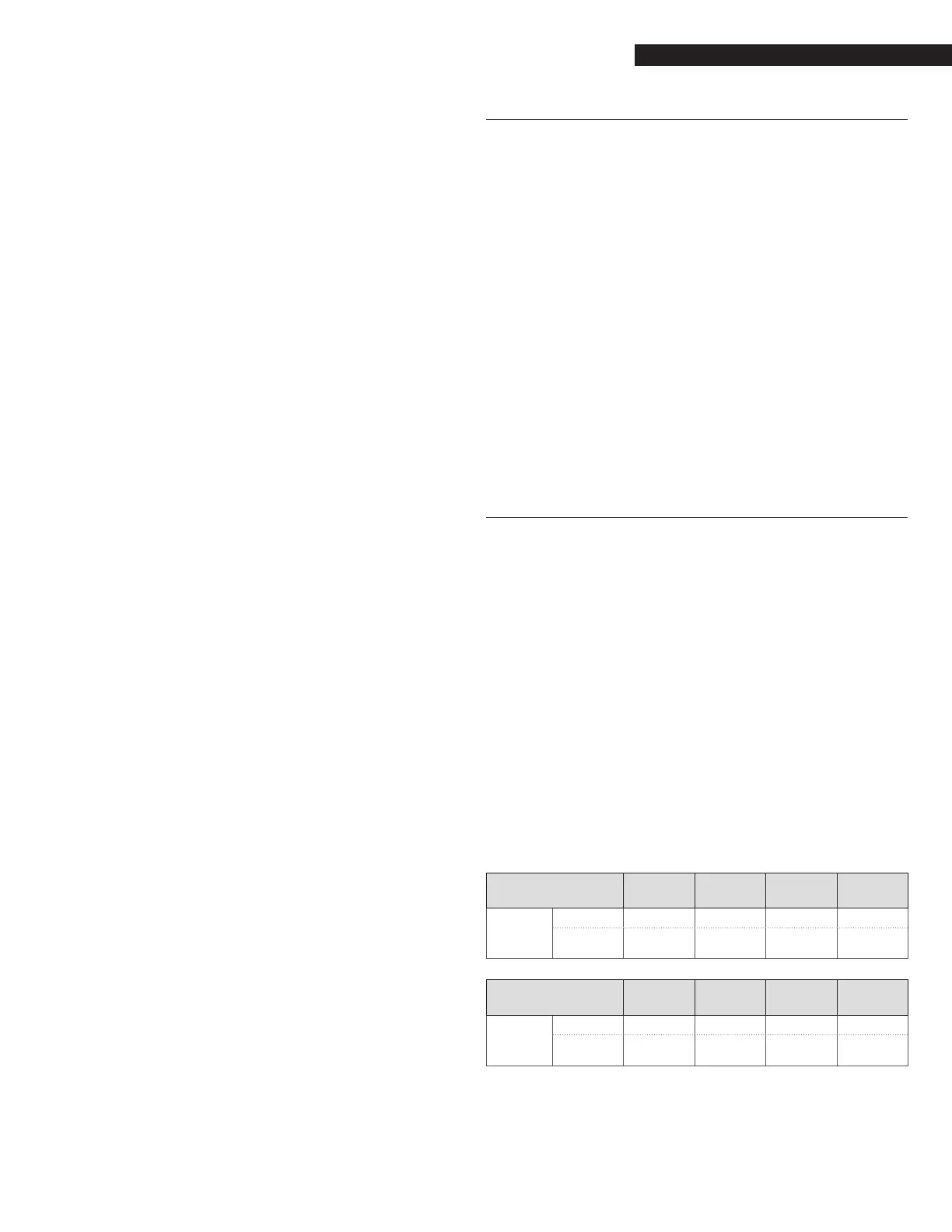

RTC 3000-

80

RTC 3800-

80

RTC 4700-

80

RTC 5500-

80

Fireside

pressure

drop

inch W.C. 2.288 2.529 2.729 2.970

mbar 5.7 6.3 6.8 7.4

At maximum output with water temps supply/return of 176/140 °F

(80/60 °C), CO2=9.7% and O2=3.6%.

Loading...

Loading...