25

INSTALLATION

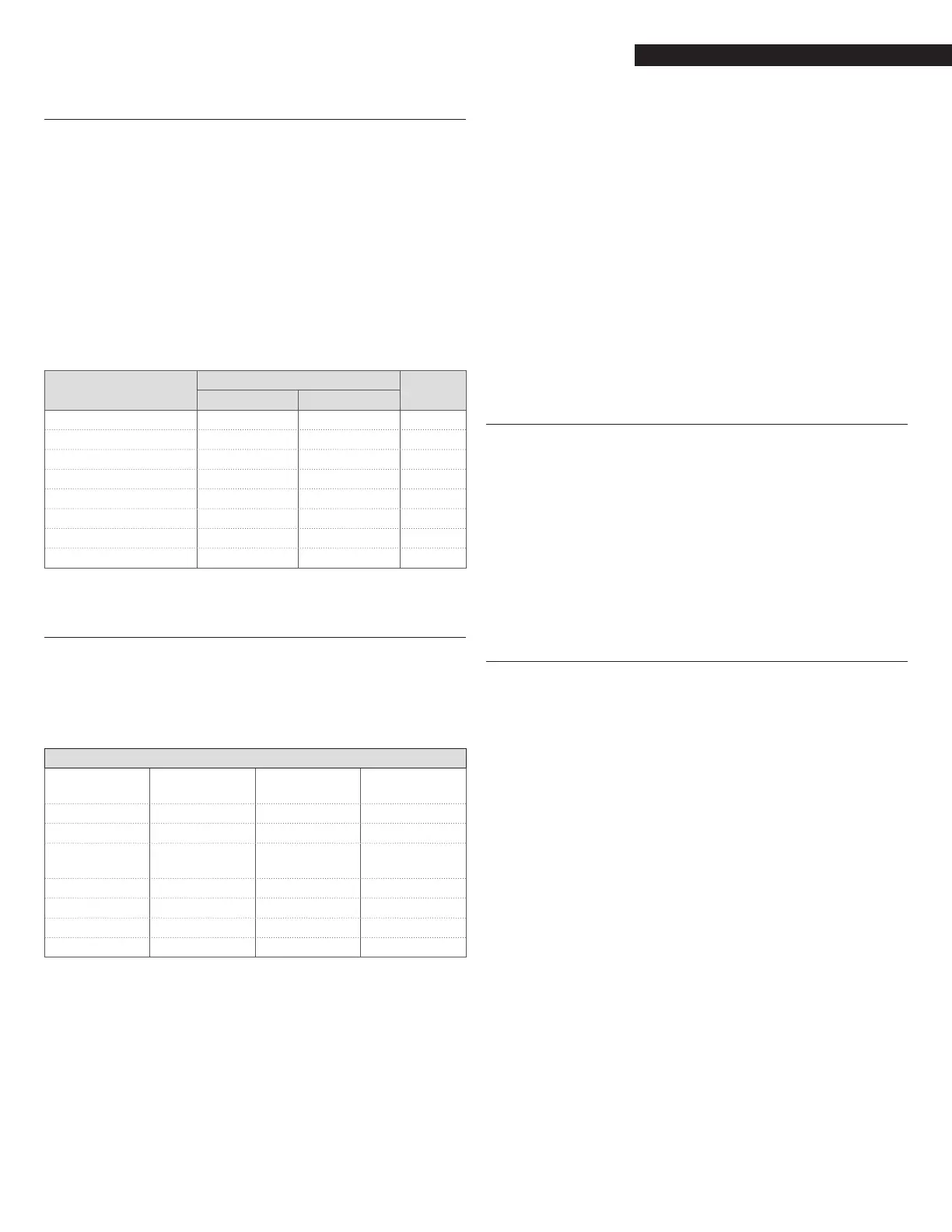

2.8.2 Flow limits

RTC-80 boilers do not require a minimum ow rate in order to

maintain warranty. The boiler has been designed to operate with

a temperature difference between the supply and return of up

to 100 °F. Flow should be initiated with the start of the burner

to minimize temperature uctuations and control deviations. The

eld installed manual reset high limit (as required by CSD-1) must

be tted to the instrument tapping of the heating supply, set to

210°F and electrically connected into the Control unit or the burner

enable/disable circuit directly.

RTC-80 boilers can operate with zero ow, and do not require a

minimum ow rate.

A minimum ow is recommended only to provide heat transfer,

and the maximum ow to prevent erosion.

Model

Flow Limits

Maximum Minimum

RTC 1000-80 130 12 GPM (*)

RTC 1300-80 160 15 GPM (*)

RTC 1700-80 200 20 GPM (*)

RTC 2300-80 290 30 GPM (*)

RTC 3000-80 370 40 GPM (*)

RTC 3800-80 480 50 GPM (*)

RTC 4700-80 580 60 GPM (*)

RTC 5500-80 690 70 GPM (*)

(*) Units shown are in US Gallons.

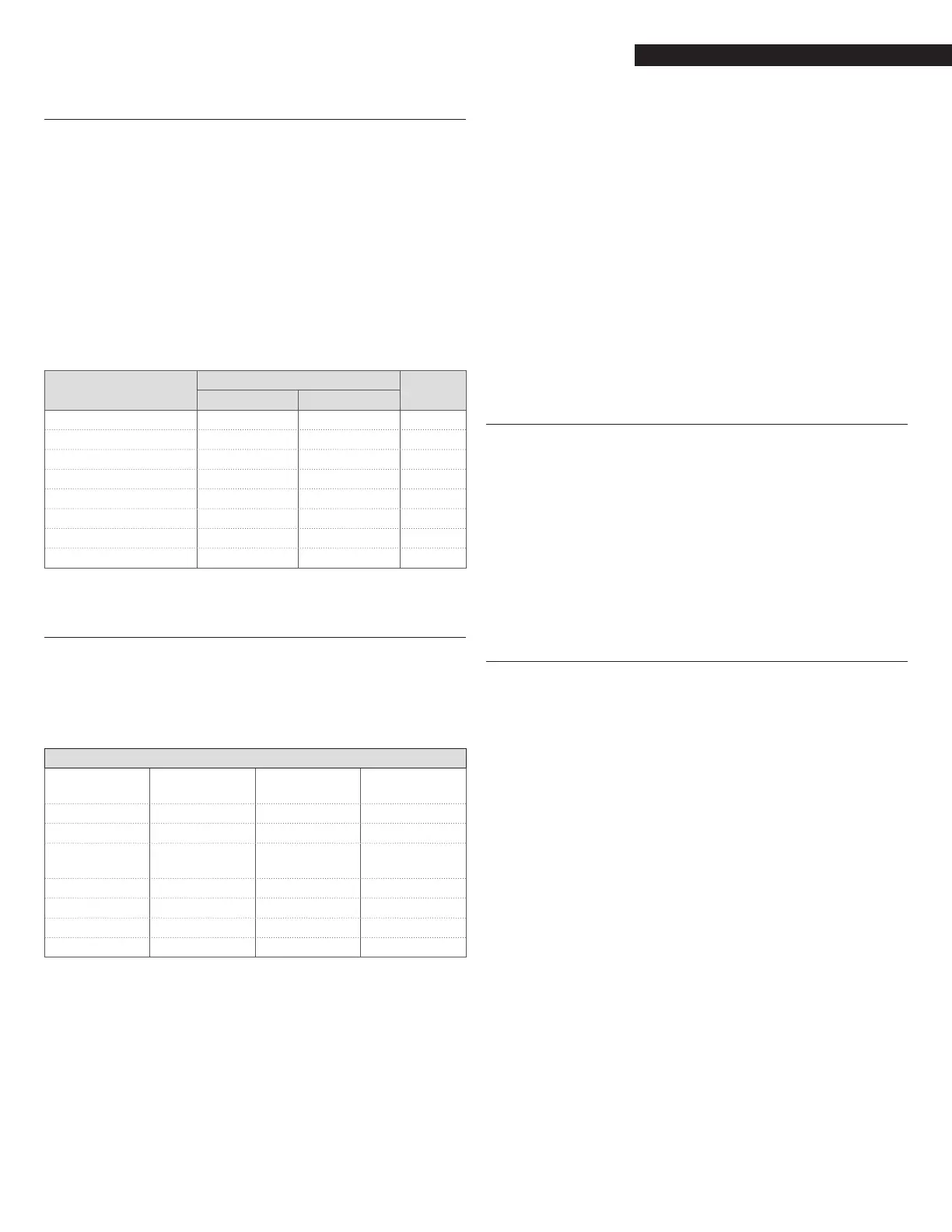

2.8.3 Water quality requirements

The manufacturer recommends the use of water as heat transfer

uid for the central heating system. A chemical treatment system

must be provided for this water.

The heat transfer uid (water) for the central heating circuit must

conform to the quality parameters given in the following table:

Chemical and physical requirements of heating system water

Initial lling

water

Regular service

water (*)

ph 6-8 7.5-9.5

Hardness °fH / ppm < 5° / 50 < 5° / 50

Electrical con-

ductivity

μs/cm < 100

Chlorides mg/l / ppm < 10 / 10

Sulphides mg/l / ppm < 10 / 10

Nitrides mg/l / ppm < 10 / 10

Iron mg/l / ppm < 0.5 / 0.5

(*) values for water in system after 8 weeks of functioning

9

NOTICE:

If it proves impossible to treat the heating system water

supply properly because the water charging system is

automatic and uncontrolled, if there are no barriers

installed to prevent water oxygenation and if the heating

system includes an open expansion vessel, then the

boiler itself must be separated from the heating system by

means of a heat exchanger.

If the hardness of the water exceeds the value specied in the

table, it is mandatory to install a water softening system.

9

NOTICE:

− Chemical products used for water treatment must be com-

patible with applicable water pollution laws.

− Provided they are properly applied, these laws guarantee

the safe functioning of the heating system.

2.8.4 Central heating system

Possible causes for corrosion and limescale

Typical problems encountered in central heating systems include:

− the breakage of heated surfaces through overheating

caused by the thermal insulation of limescale deposits on

the water side

− oxygen corrosion

− deposit corrosion

− stray current corrosion

− diffused and localized acid corrosion.

The technical details provided in this section refer specically to

domestic and industrial hot water heating systems with working

temperatures up to 210°F (99°C).

2.8.5 New central heating systems

Mistakes to avoid and precautions.

To eliminate contact between system water and the air, the fol-

lowing is required:

− ensure that the expansion vessel is a closed vessel, and

of the correct size and pre-charge pressure (the pressure

should be checked periodically)

− ensure that the system is always kept at a pressure high-

er than atmospheric pressure at all points (including the

pump suction side) and at all operating conditions (pre-

cisely because the seals, gaskets and joints in a water cir-

cuit are designed to resist pressure from within, but not to

resist a vacuum within)

− ensure that no part of the system is made from materials

that are permeable to gases (e.g. plastic pipes with no ox-

ygen barrier used in oor heating systems).

9

NOTICE:

The original system lling water and any topping up water

must always be ltered (using synthetic or metal mesh

lters with a ltration rating of no less than 50 microns)

to prevent sludge from forming and triggering deposit

induced corrosion.

9

NOTICE:

We recommend tting an 80 mesh dirt lter externally to

the boiler return to prevent contamination of the boiler by

the water source.

Loading...

Loading...