23

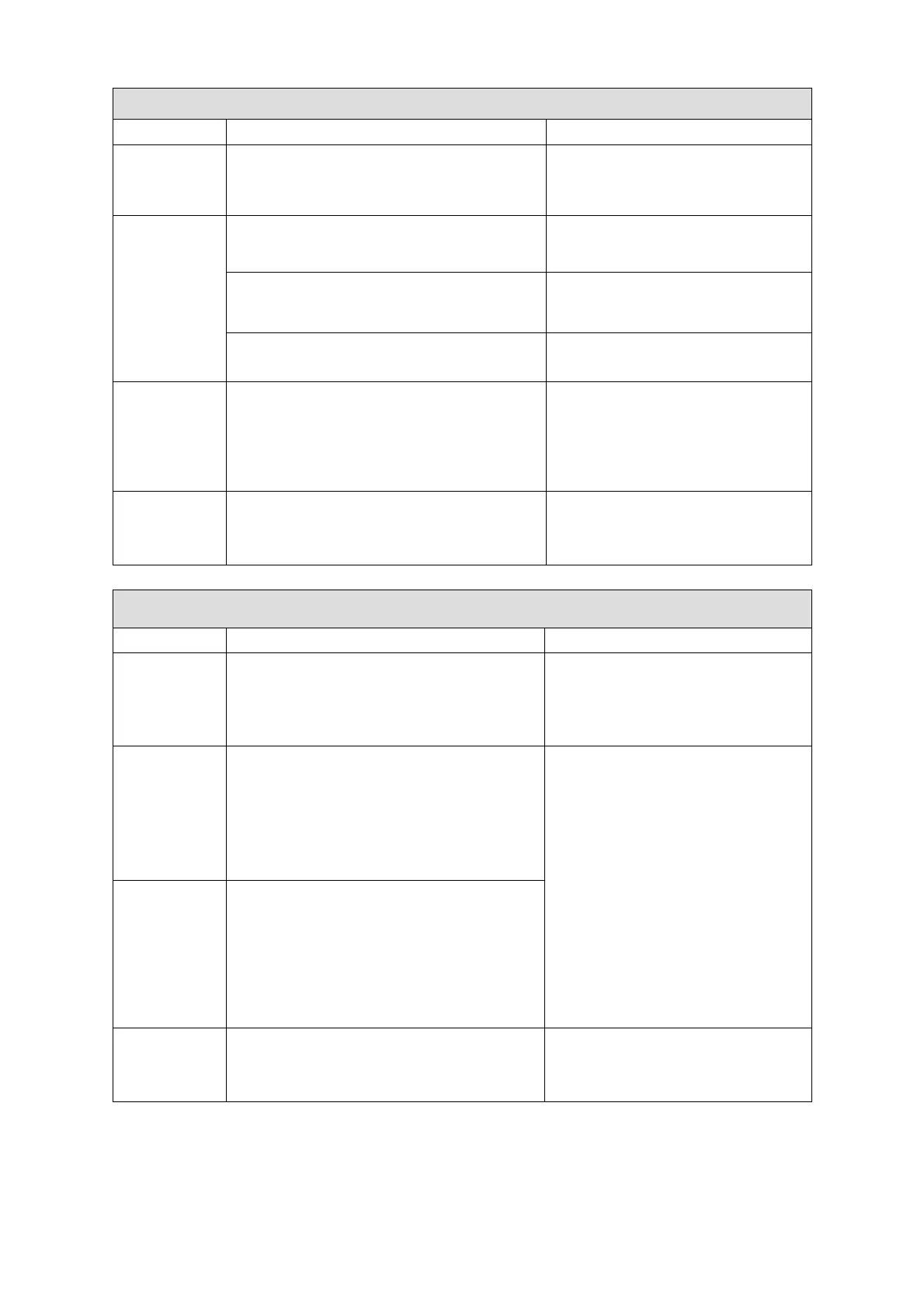

WIRE FEEDER

Position Check points Remarks

Pressure

arm

Appropriate positioning of the pressure

arm

Poor wire guidance and unstable

arc

Wire lead

tube

Accumulation of dirt or residue in the

mouth of the tube

Clean the residue, find the source

of the problem and solve it

Wire diameter matches the tube’s inner

diameter

If unmatched, may cause residue

buildup or unstable arc

Tube diameter matches the wire wheel

slot center. (Eyeballing)

If unmatched, may cause residue

buildup or unstable arc

Wire wheel

Wire diameter matches the wheel’s

requirement

If the wheel slot is blocked

1.May cause residue buildup,

unstable arc and block wire tube

2.Change for a new one, if

necessary

Pressure

wheel

Check the stability of its move, and

wearing-out of pressed wire, the

narrowing of its contact surface

Poor wire guidance and unstable

arc

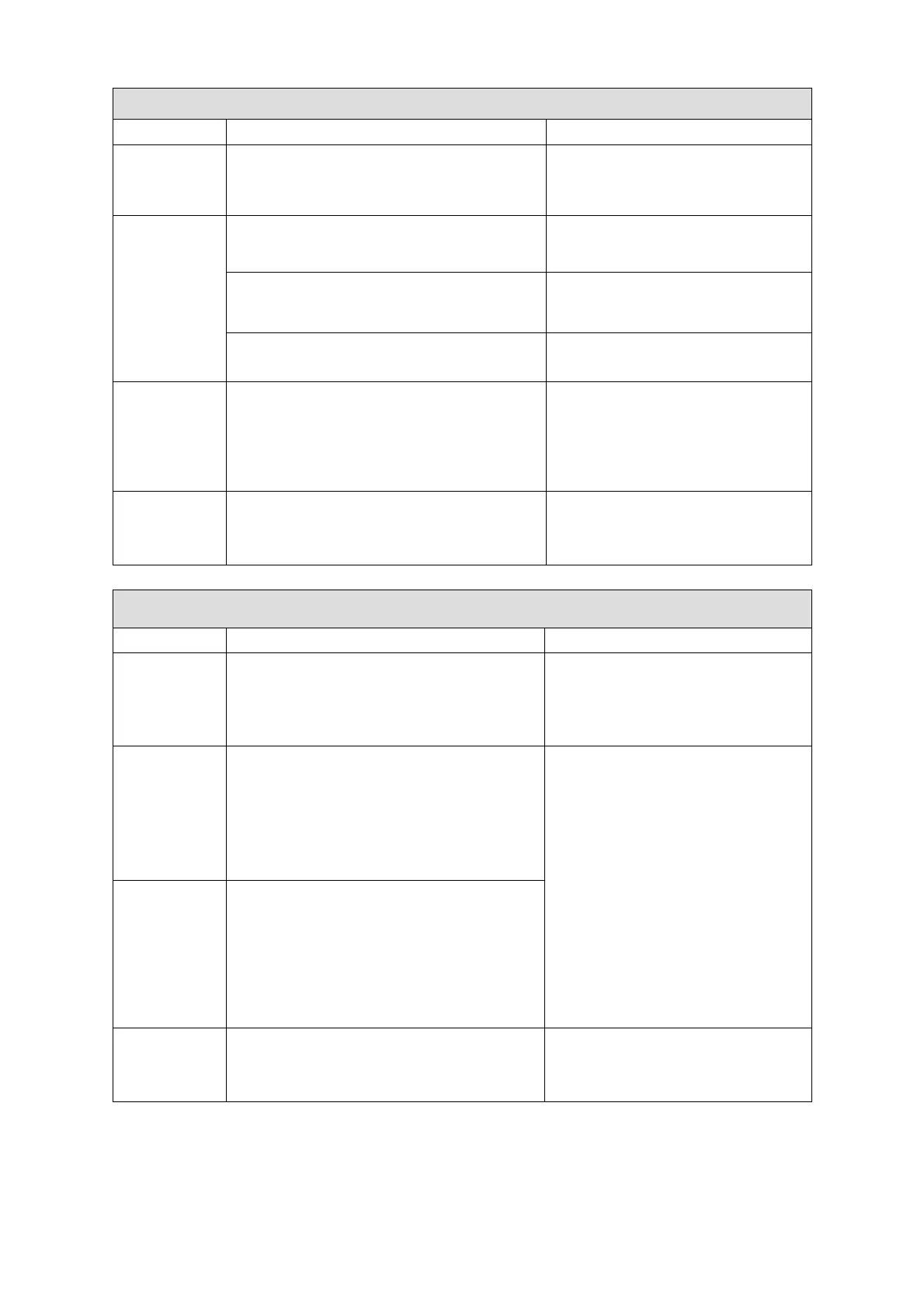

CABLE

Position Check points Remarks

Torch cable

1. If torch cable is twisted

2. Loosening of metal connection point of

the mobile plug

1. Poor wire guidance

2. Unstable arc if cable is twisted

Output cable

1. Wear of the cable insulating material

2. Cable stripped (insulation damage), or

loosened (the end of power supply, and

cable of main material connection

point)

Follow the appropriate safety

measures and welding methods to

perform these verifications

depending on the workplace.

Daily routine checks

In-depth checks on fixed

periods

Input cable

1. If the connection between the plug and

the power socket is firm

2. If the power input end cable fixed

3. If the input cable is worn out and bares

the conductor

Earth cable

State of the earth cable and its

connections

Loading...

Loading...