10

INSTALLATION INSTRUCTION

The welding equipment is equipped with power voltage compensation device. It keeps the machine

working normally when power voltage fluctuates ±15% of rated voltage.

When using long cable, in order to reduce voltage drop, big section cable is suggested. If the cable is

too long, it will affect the performance of arcing and other system functions, it is suggested to use the

recommended length.

1. Make sure the intake of the machine is not covered or blocked to avoid the malfunction of the

cooling system.

2. Make sure the earth end of power interface has been reliably and independently grounded.

Installation Procedures:

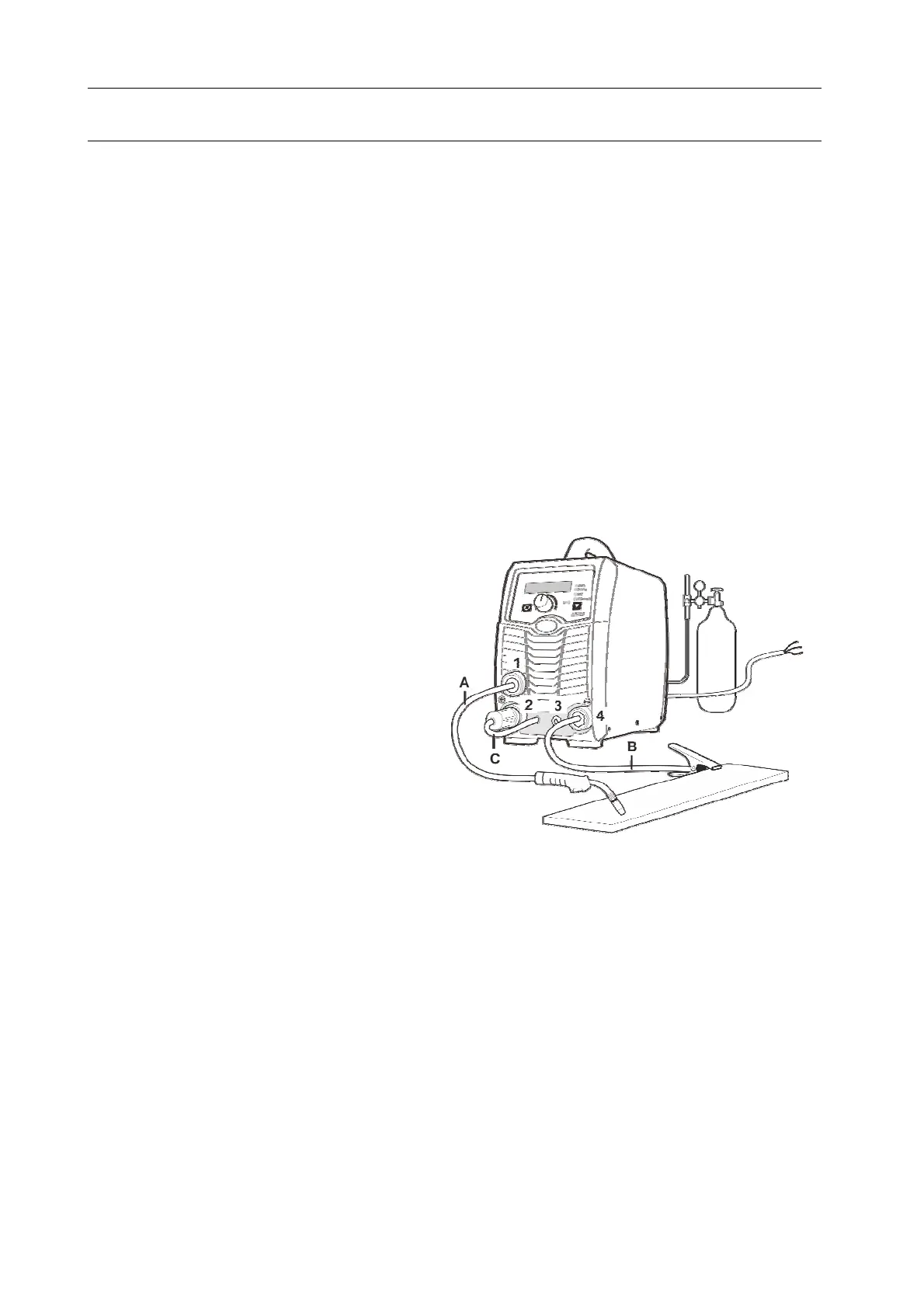

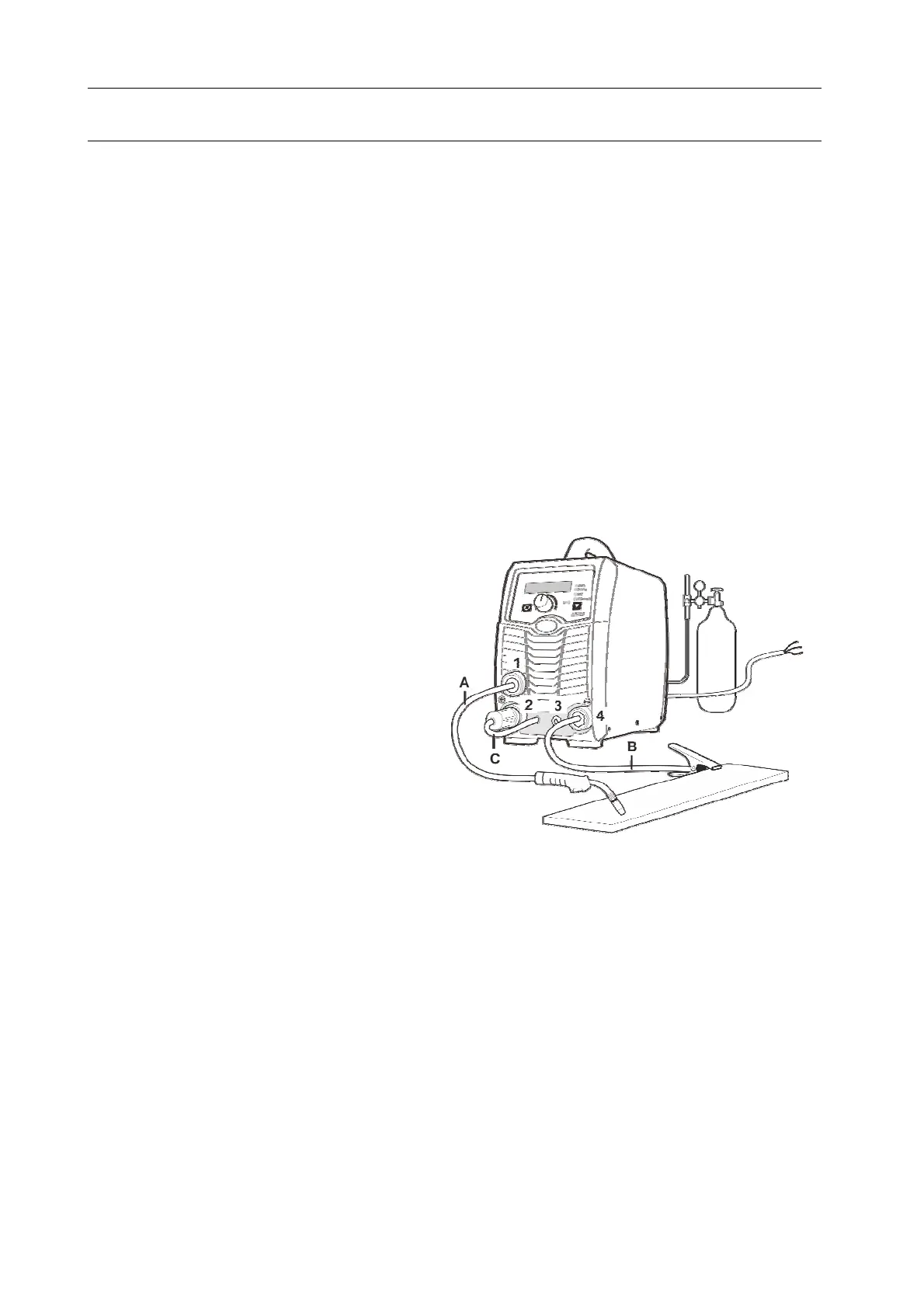

Installation for MIG process

1) Connect the gas cylinder to the regulator. Select correct shielding gas for the application.

2) Fit the wire spool to the machine. Select

correct welding wire for application.

3) Select the appropriate feed roller to suit the

wire being used.

- V groove for use with solid carbon

manganese and stainless steel.

- U groove for use with soft wires such as

aluminum.

4) Loosen the wire feed tension screws an

insert the wire. Refit and tension roller

ensure the wire is gripped sufficiently so a

not to slip but avoid over-tightening as this can affect feed quality and cause wire feed components

to wear rapidly.

5) Fit and tighten the torch (A) on the output connection (1). Ensure correct torch liner and contact tip

are selected.

6) Selectthecorrectpolarityforthetypeofwireusedasindicatedontheconsumable packaging.

This is achieved by swapping the polarity terminal wires. For most solid wires the terminal should

be set as torch positive.

For torch positive, plug the short mechanical connector (C) on the front panel into the positive

terminal (2) and the work return lead (B) into the negative terminal (4).

For torch negative, plug the short mechanical connector (C) into the negative terminal (4), and

the work return lead (B) into the positive terminal (2).

Loading...

Loading...