22

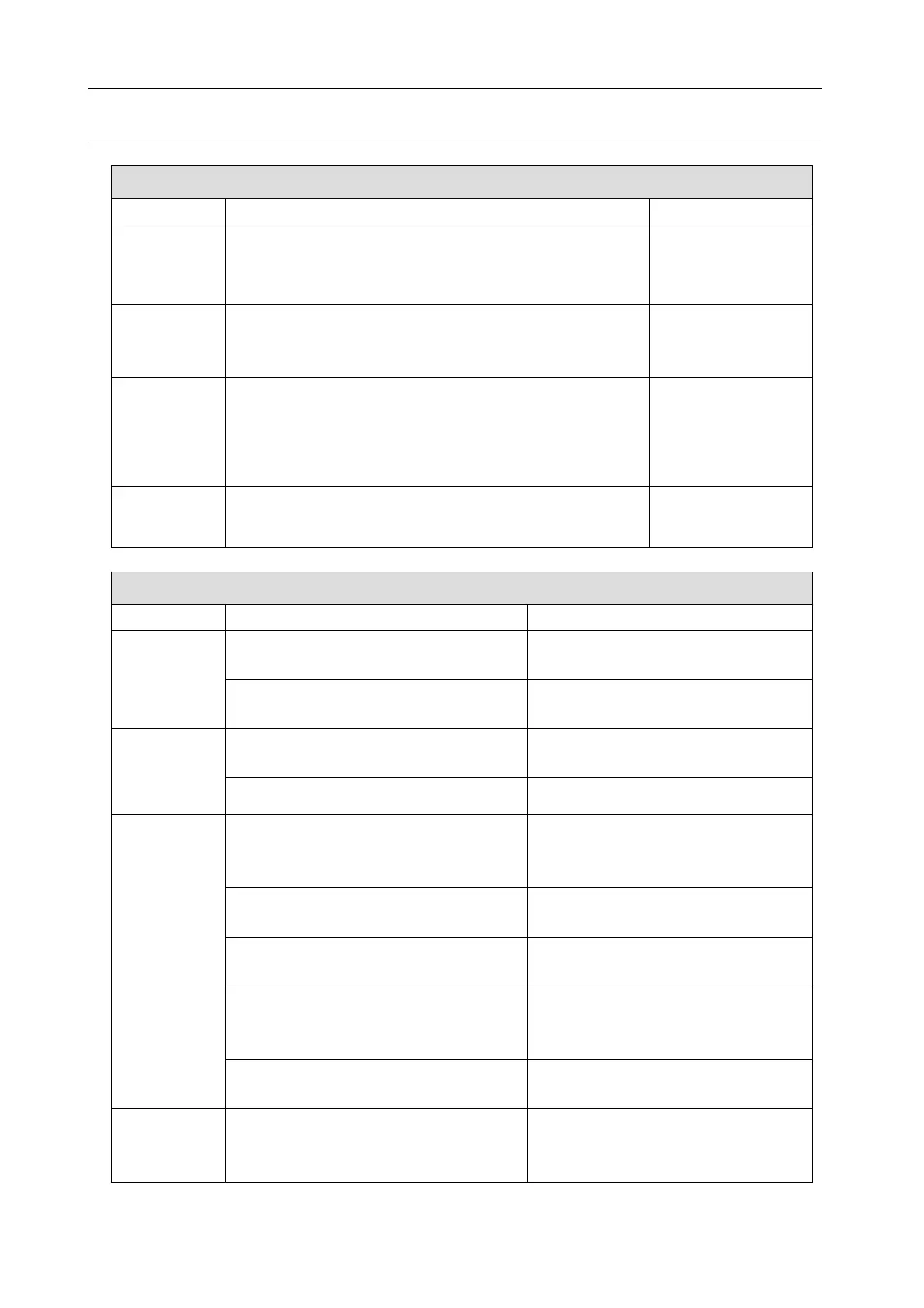

DAILY CHECKING

WELDING POWER SUPPLY

Position Check points Remarks

Control panel

1. Condition of operation, transfer and installation of

switches

2. Check the power indicator

-

Cooling fan 1. Check if there is wind and if the sound is normal

If abnormal noise

and no wind, check

theinsideofthefan

Electrical

components

1. When power on, abnormal smell

2. When power on, abnormal vibration or buzzing

3. Color changing and heating in appearance

-

Peripheral

components

1. Gas pipe is broken or loose

2. Housing and other fixed parts loose

-

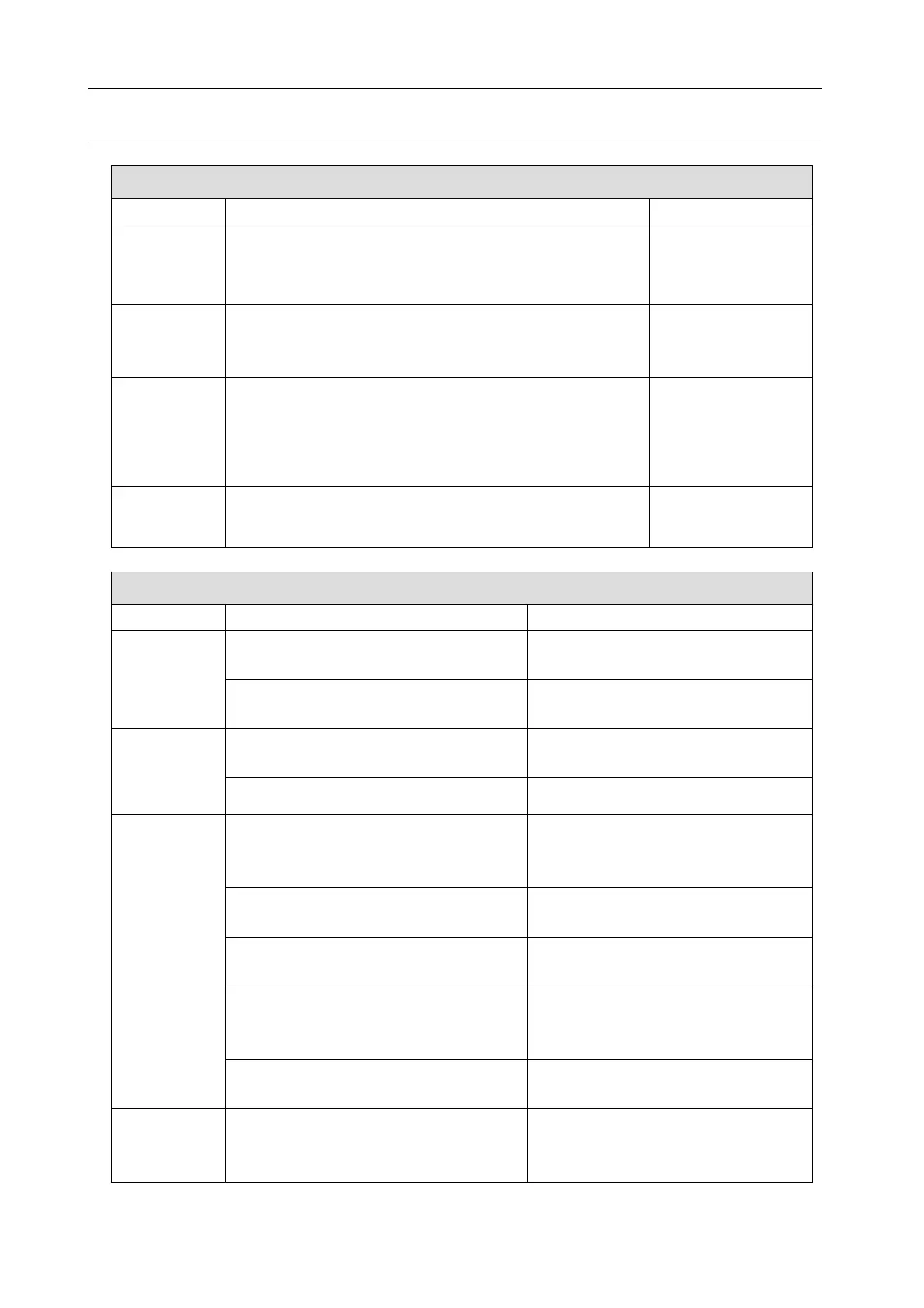

WELDING TORCH

Position Check points Remarks

Nozzle

Adequate mounting. Presence of

distortion

Reason for air leaks

Presence of splashes

Reason for burns in the torch

(can use spatter-proof material)

Electric hole

Adequate mounting

Reason for torch screw thread

damage

Damage of its head and hole blocked Reason for unstable and irregular arc

Wire guide

tube

Check the extended size of the tube

Change when less than 6mm, when

the extended part too small, to

ensure arc stability

Wire diameter matches tube inner

diameter

Reason for unstable arc, please use

thesuitabletubediameter

Partial bending and extended

Reason of poor wires guiding and

unstable arc, please change

Blockage caused by dirt or residue in

the tube

Reason of poor wire guiding and

unstable arc, (use kerosene to wipe

or change tube)

Wire guide tube broken

Pyrocondensation tube broken,

change tube

Gas bypass Poor connection or blockage of the hole

May cause spatter due to improper

gas shield, unstable arc or burns to

the torch body

Loading...

Loading...