26

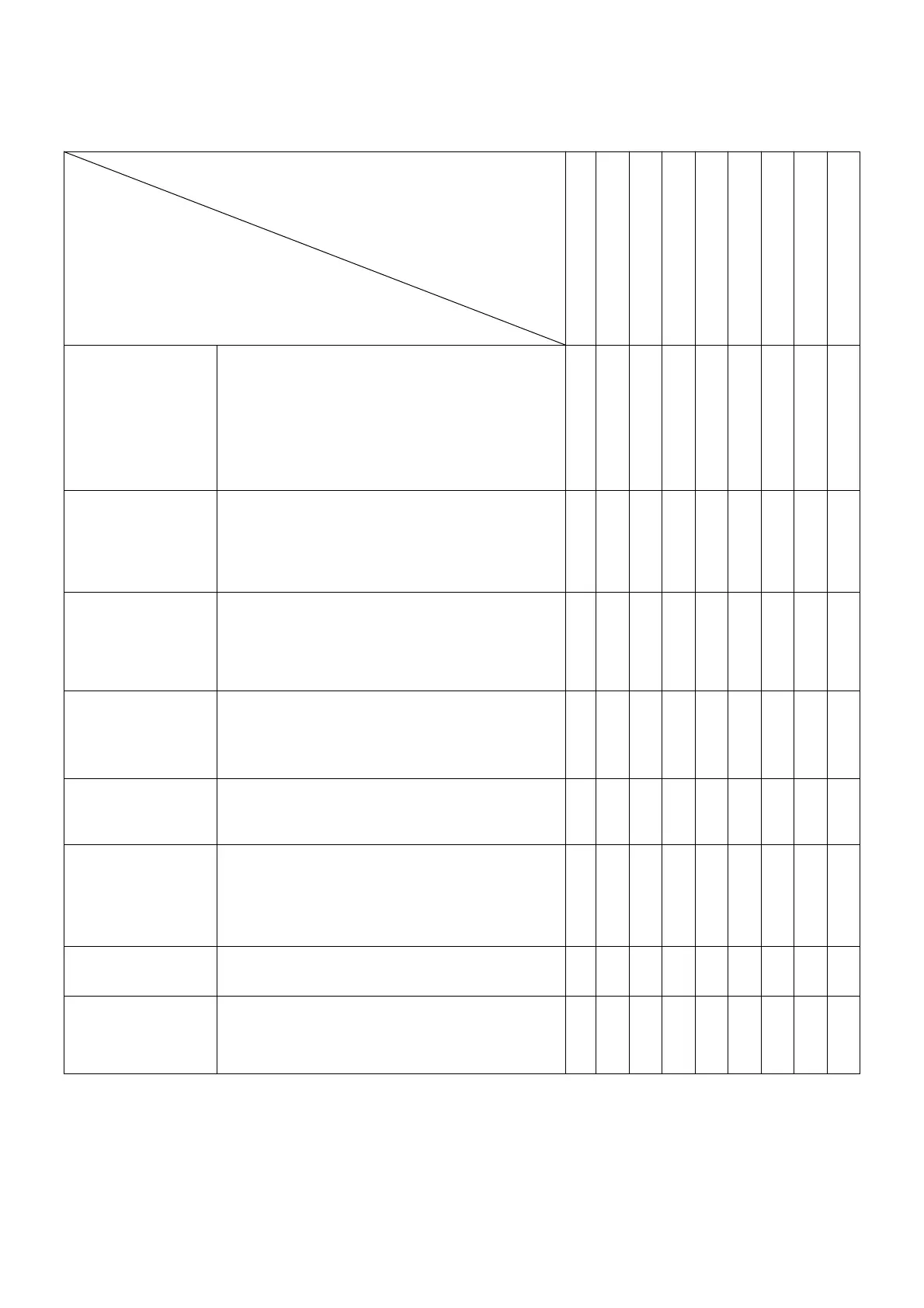

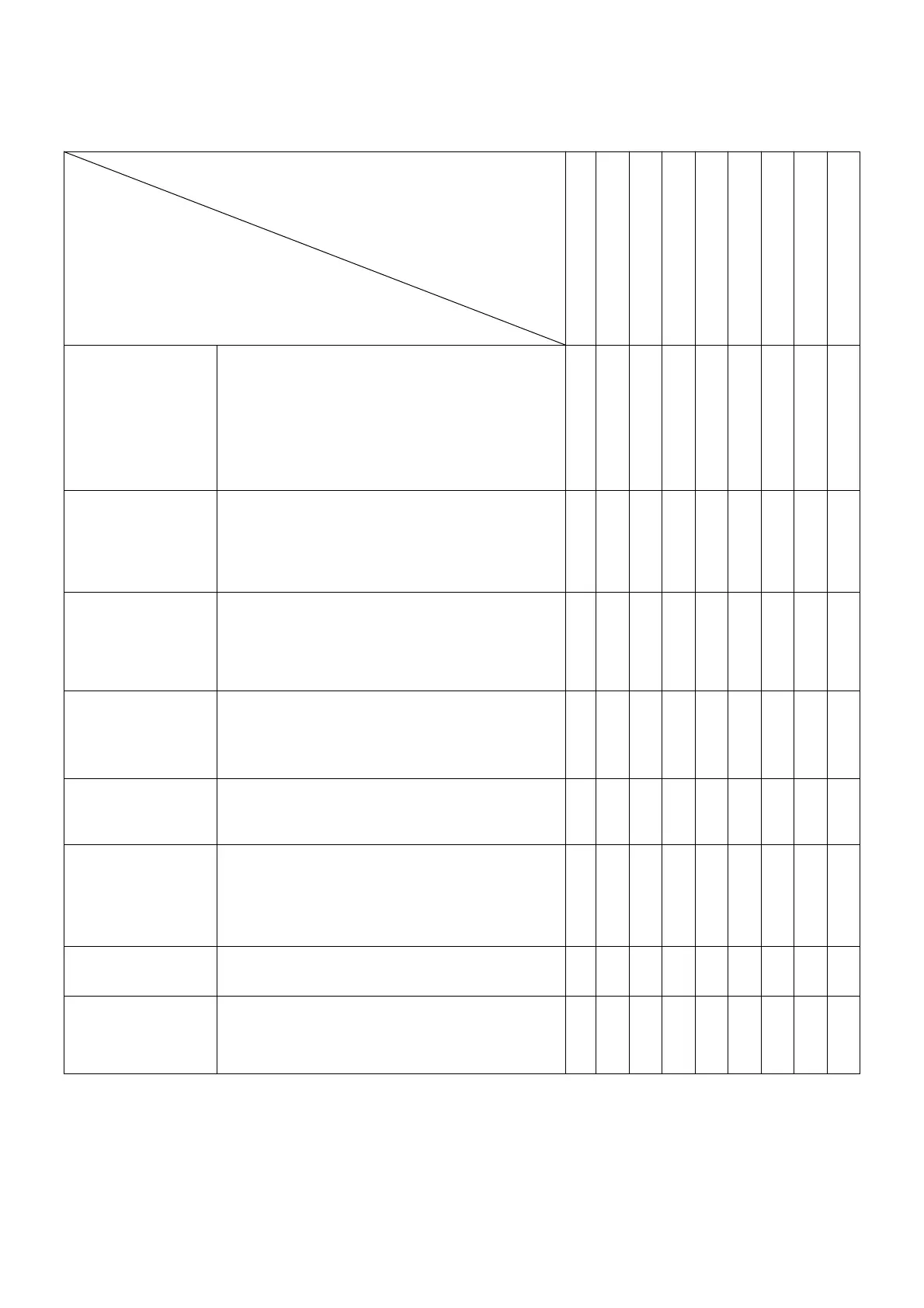

Initial problems diagnosis

Abnormal Items

Check points and Maintenance

No arch

No Gas out

No Wire Feeding

Bad Arc Ignition

Unstable Arc

Dirt on Edge of Weld Sea

Wire Stick to Parent

Wire Stick to Conductive Tip

Blowhole Formed

Wire Feeder

1. Wire spool does not match the diameter of wire in

guide tube

2. Defective wire feeding wheel or groove blocked

3. Handle too tight or loose

4. Metal powder accumulated on the inlet of SUS

hose

〇〇〇〇 〇

Weld Gun and Cable

1. Welding gun cable twisted

2. Wear, blockage or deformation in the welding gun

assembly (contact tip, gas hose, cable, etc.)

〇〇〇 〇

Body of welding gun

1. Loose connection of contact tip, nozzle and nozzle

contactor

2. Contactor of welding gun body is not properly

inserted or tightened

〇〇

Power supply cable of

welding gun as well

as cable of switch

control

1. Wear caused by improper cable winding

2. Damaged by weighted drop

〇〇〇 〇 〇

Wire length and

conditions of related

material

1. Oil, dirt, rust and paint residues

2. Wire too long

〇〇〇〇 〇

Output Cable

1. Insufficient section of cable connected to related

materials

2. Poor connection to(+), (-) output cable

3. Poor electric conductivity of related materials

〇〇〇

Lengthened Cable

1. Insufficient cable section

2. Folded or twisted cable

〇〇〇〇

Welding Work

Conditions

Welding current, voltage, angle of welding gun,

welding rate and wire length should be confirmed

once again

〇〇〇〇〇

Loading...

Loading...