01/18 57

9TROUBLESHOOTING

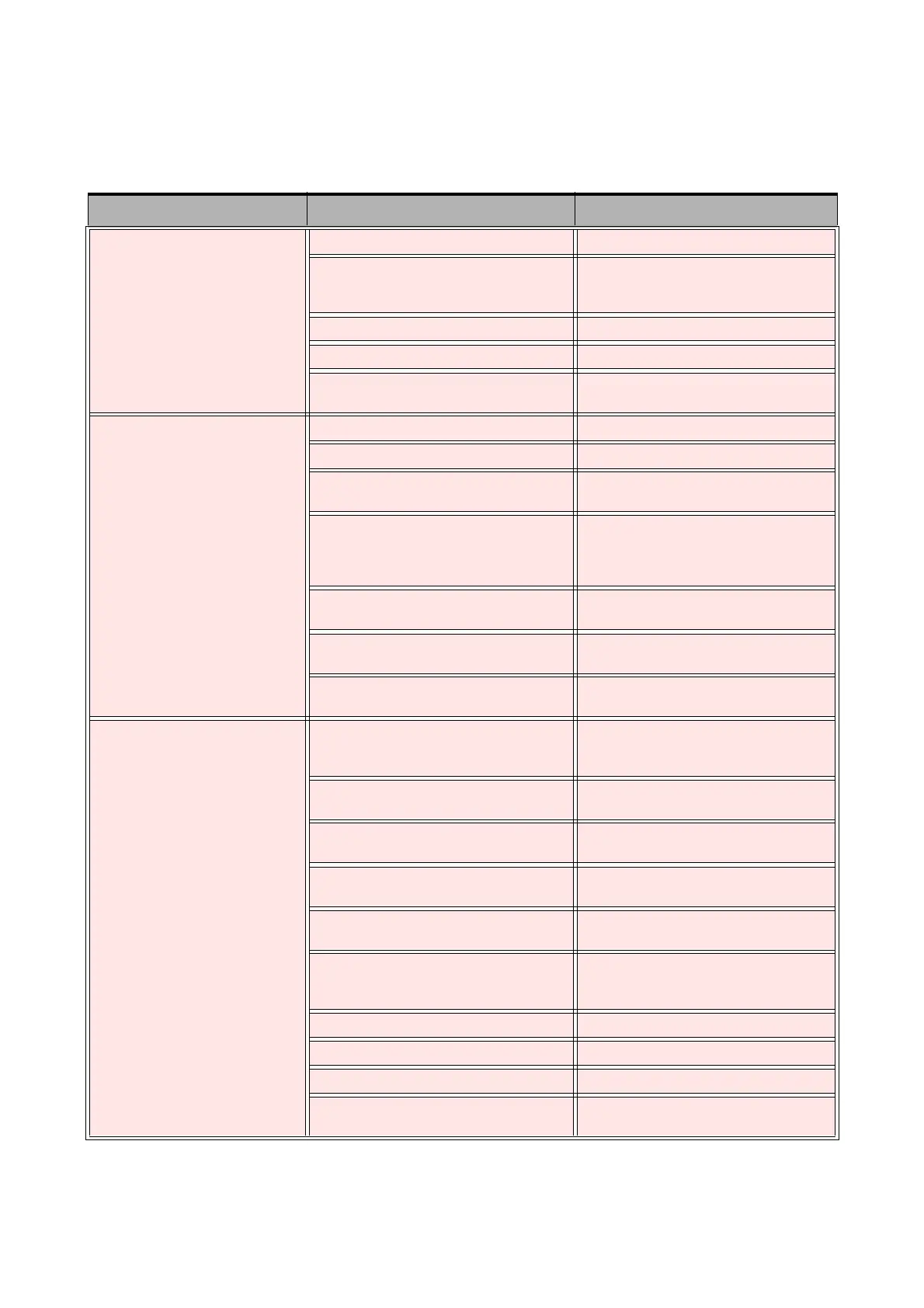

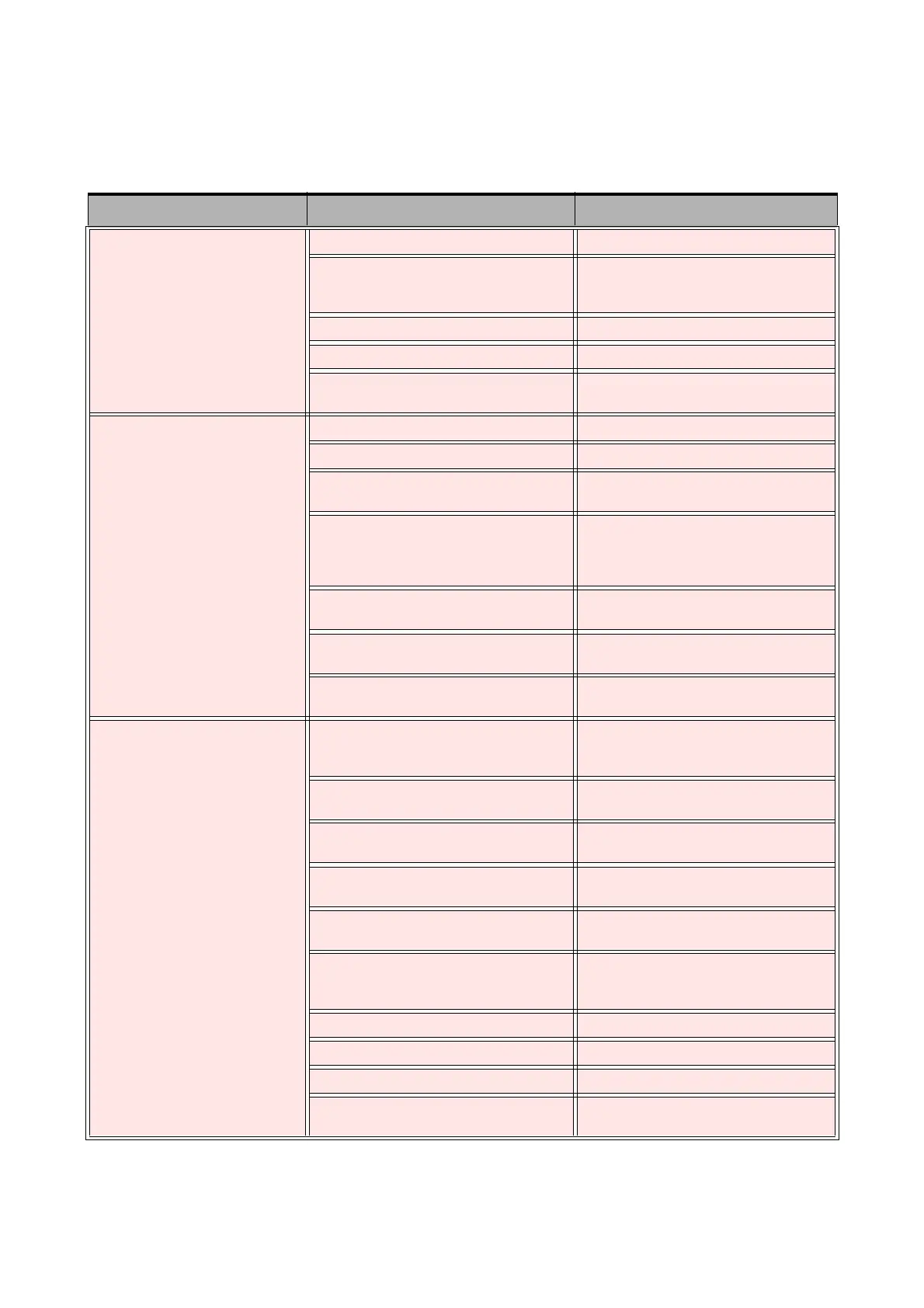

Failure Reason Solution

Engine does not start or stops

abruptly.

Machine has run out of fuel Add fuel

Main or secondary fuse blown Replace the defect fuse and restart

engine. If problem repeats, contact

your dealer

Battery voltage too low. Load or replace.

Air in fuel line Drain the engine

Emergency stop activated Turn the emergency stop in order to be

able to start up again

The high-pressure pump does

not produce the required pres-

sure.

Water tank empty Fill the water tank

Supply valve to water filter closed. Open the supply valve

Water filter clogged. Stop the machine and clean the water

filter

Air in high-pressure pump Allow the machine to run a few min-

utes. The failure will normally disap-

pear. If not, contact the service

department of your dealer

Suction valves blocked Carefully loosen the valves and des-

cale them, if necessary

V-belt not sufficiently tightened Tighten the V-belt; replace if neces-

sary

Suction valves worn out. Contact the service department of

your dealer.

Pressure varies. Water level in tank too low Stop the engine, refill the tank and

restart engine

Water supply valve not sufficiently

opened

Open the supply valve completely

Water filter clogged. Stop the machine and clean the filter

Pump sucks air Stop the machine and check all hoses

and couplings for leakage

Nozzle clogged Stop the machine and clean the nozzle

(clean the nozzle holes)

Pressure valves dirty or worn Stop the machine. Check the condition

of the pressure valves. Clean or

replace them

Pump gasket worn out Stop the machine and replace gasket

V-belts for the pump slip Stop the machine and tighten the belts

Ceramic plungers in the pump damaged Contact your dealer

Pressure control clogged or internally

damaged.

Contact your dealer.

Loading...

Loading...