Trainer 40 Instructions

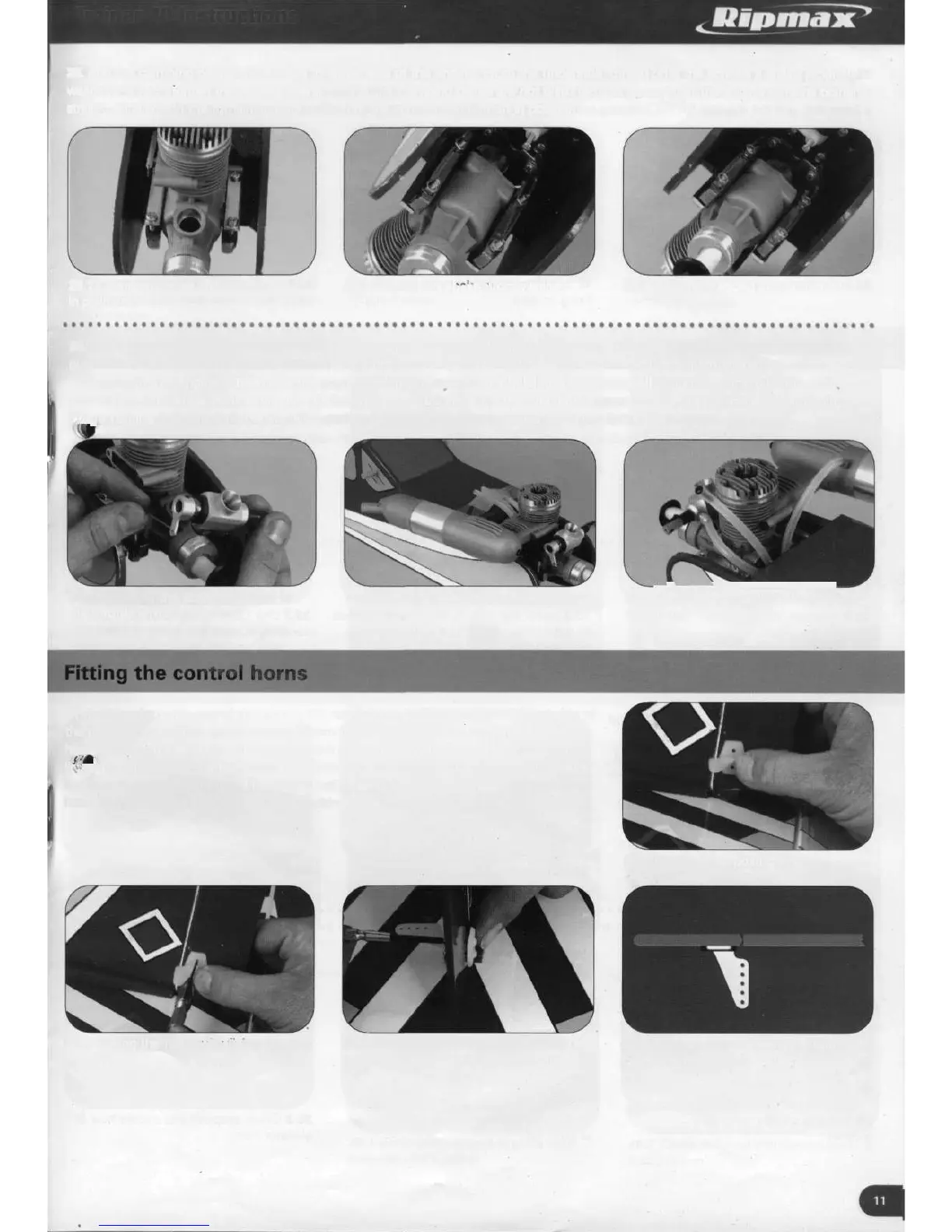

29. Add the clamping plates and screws to either side of the engine. From the underside, thread onto the screws a shake proof

washer and nut. Tighten the screws evenly so that the clamping plates are not distorted and ensure that the engine remains pointing

straight. Finally, add the remaining nuts to each of the screws and tighten in position.

29.1 Clamping plates and screws

in position

29.2 Adding the shake proof washer

and nut

29.3 Lock nuts added and tightened

30. The engine's throttle is controlled by the movement of a pushrod located in the front, upper part of the fuselage. Thread the

pushrod's Z bend into a hole in the carburettor's throttle arm and, following the engine manufacturer's instructions, secure the

carburettor to the engine. Attach also the engine's silencer, ensuring the holding screws are well tightened. Trim to length and

connect the fuel tank's clunk tank outlet to the engine^ carburettor and the fuel tank's upper vent to the silencer's pressure nipple.

T^remaining fuel tank outlet is the filling port and the tubing is simply sealed using a suitable clean screw.

30.1 Attaching the pushrod Z bend to

the throttle arm

30.2 Securing the engine's silencer

in place

30.3 Connecting the fuel tubing to

the engine

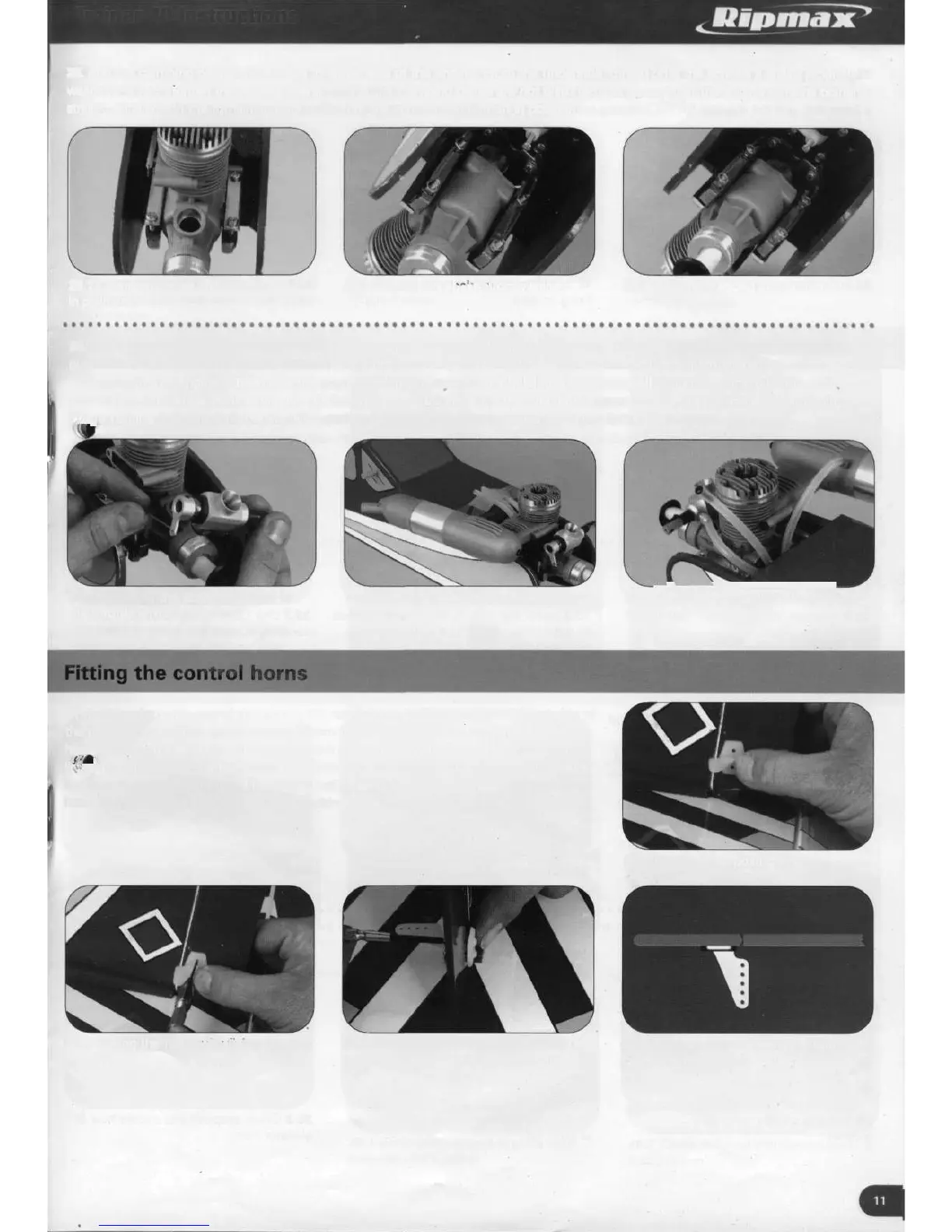

31. Looking from the rear of the model, the rudder horn is fitted on the left hand side of

the rudder at a position approximately 25mm from the base of the rudder. Hold the

horn in place on the rudder, aligning the horn clevis holes with the rudder hinge centre

lir ^pbnd drill through the horn mounting holes into the rudder with a 2mm drill. Secure

the horn in position with two 11 mm long self tapping screws which pass through the

horn, into the rudder and into the horn backing plate.

31.2 Drilling the rudder for fixing screws

31.3 Securing the horn to the rudder

using two screws and backing plate

31.1 Rudder horn position

31.4 Position horn holes in line with

control surface hinge

Loading...

Loading...