Trainer 40 Instructions

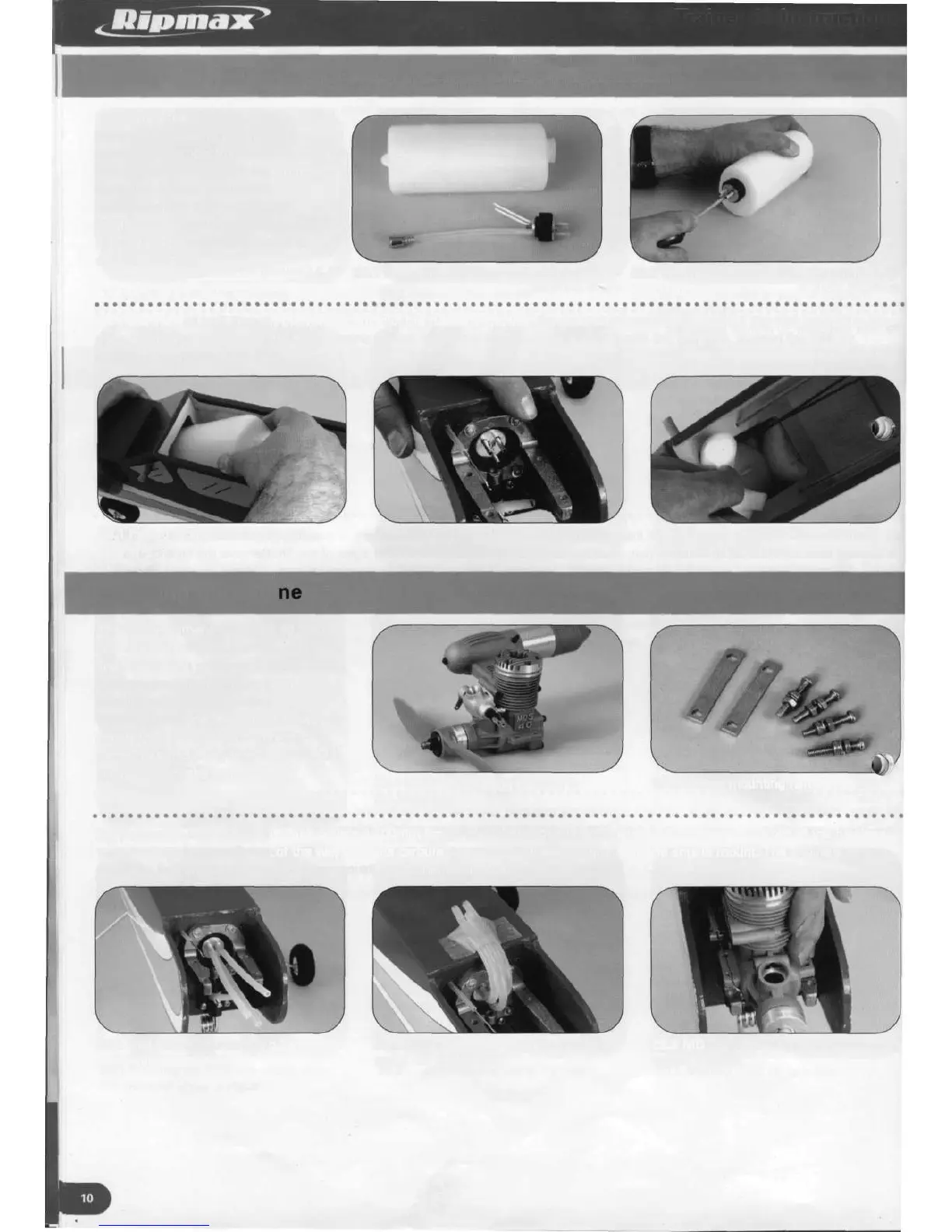

Fitting the fuel tank

25. Identify the fuel tank and its

hardware. Following the diagrams

included, assemble the fuel tank

ensuring that the clunk is free to move

from side to side and up and down. This

will ensure that fuel is delivered

to the engine regardless of the model's

attitude. Tighten the bung screw to

seal the fuel tank.

25.1 Fuel tank and clunk assembly 25.2 Sealing the fuel tank by tightening

the bung screw

26. Pass the fuel tank through the wing opening in the fuselage and into the nose of the model, the neck of the tank protruding into

the opening at the centre of the metal engine mount. Using the foam packing supplied with the fuel tank, support the tank by

packing it around the tank bay.

26.1 Pass the tank into the fuselage

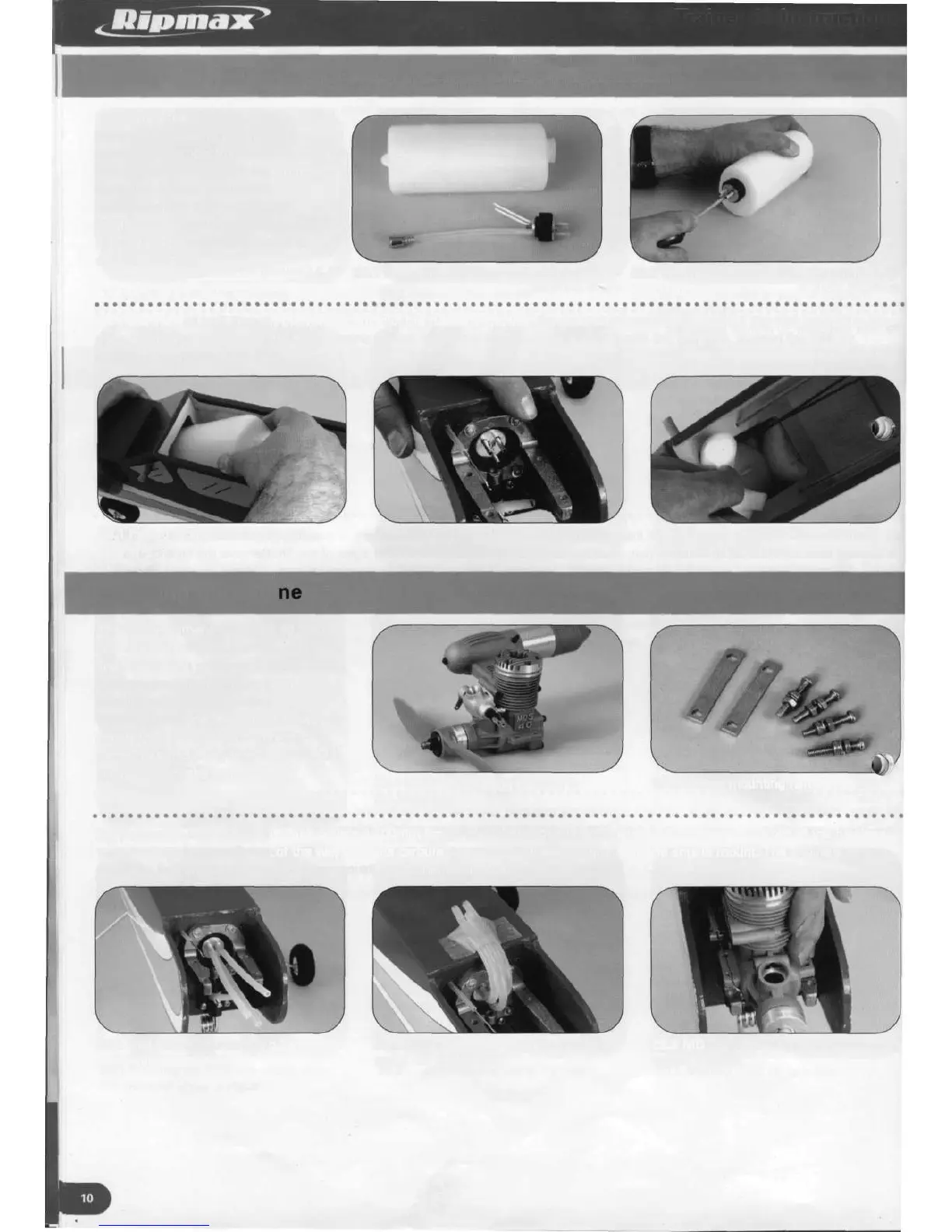

Installing the engi

26.2 Fuel tank neck protruding through

engine mount former

26.3 Support the fuel tank using the

foam packing supplied

27. We recommend the MDS 40 PRO

two stroke engine for powering the

Trainer 40. This powerful, easy to handle,

quiet engine will give many hours of

trouble free, smooth running.

Identify the engine mounting hardware

consisting of two metal clamping

plates, four mounting screws, four shake

proof washers and eight nuts.

27.1 MDS 40 PRO engine used in

the prototype

27.2 Engine mounting hardware

28. Connect to each of the fuel tank outlets a 100mm length of fuel tubing. Their free ends can be taped to the top of the fuselage

to keep them temporarily out of the way. With its carburettor removed, place the engine in the engine mount. The engine's

mounting lugs should sit over the grips moulded into the mount.

28.1 Fuel tubing connected to fuel 28.2 Fuel tubing free ends temporarily 28.3 MDS 40 PRO engine in position on

tank outlets taped out of the way engine mounts

Loading...

Loading...