Trainer 40 Instructions

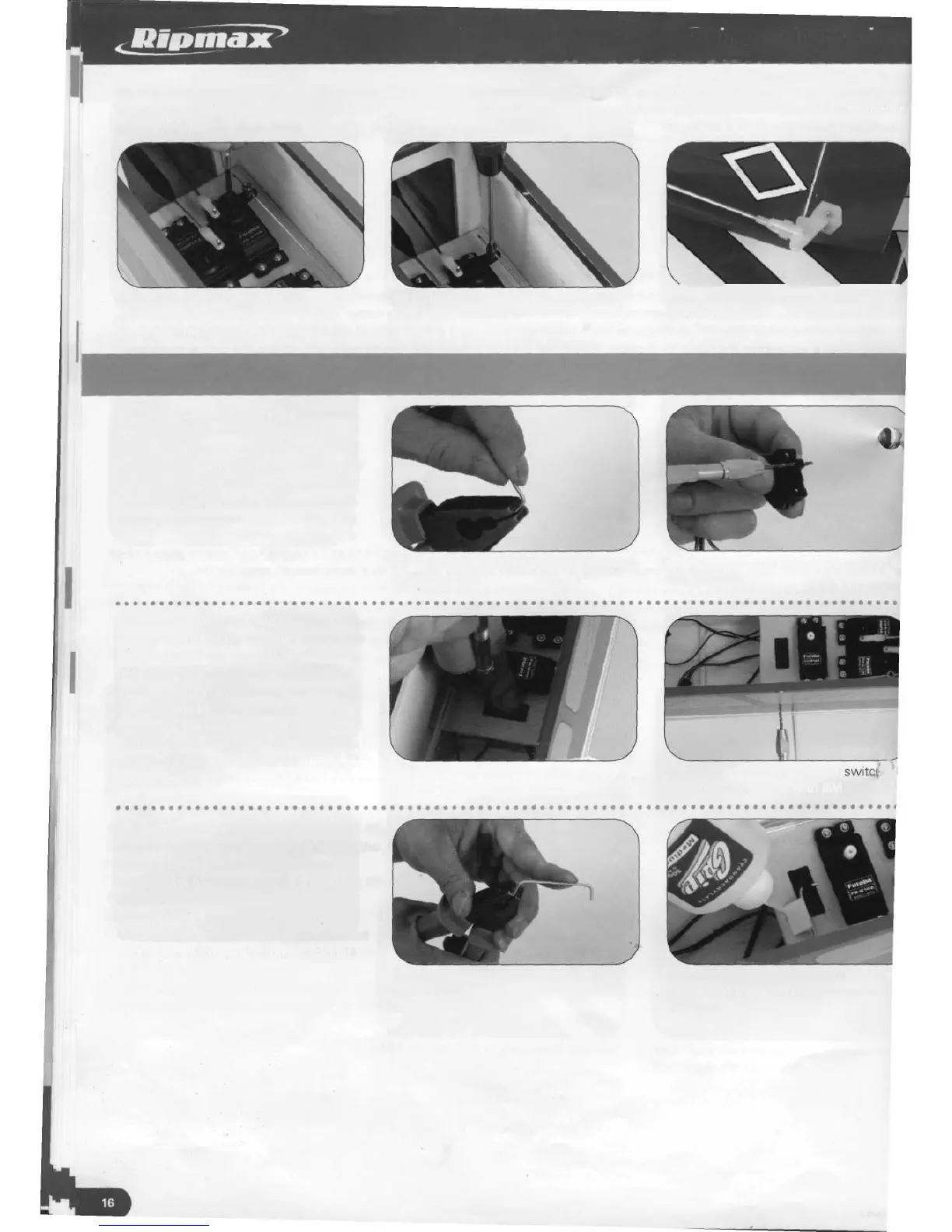

49. Pass the pushrod again through the connector and replace the arm onto the servo, securing in place with the radio

manufacturer's screw. With the wheel held centred, tighten the grub screw of the connector onto the pushrod. Re-attach the rudder

clevis and slide the clevis keeper closer to the horn.

49.1 Nose leg pushrod through

connector and securing servo arm in

place with manufacturer's screw

49.2 Tightening connector grub screw

with wheel centred

49.3 Clevis replaced and clevis keeper

in final position

Installing the receiver switch

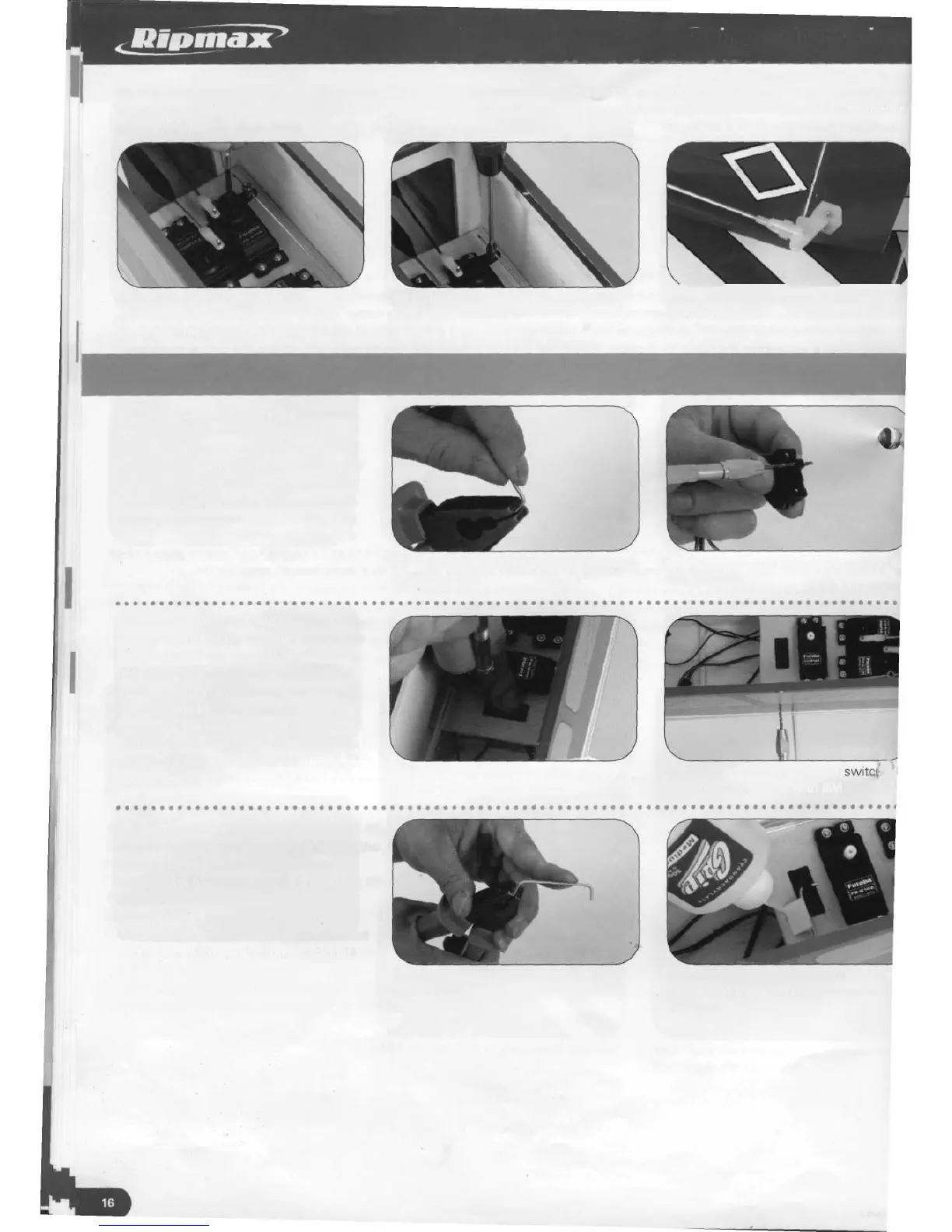

50. Form the switch operating arm from

one of the discarded pieces of wire

pushrod. Bend a 90 degree bend of

approximately 8mm length on one end of

the wire. Check the fit of the wire in the

hole in the switch and if necessary open

out the hole to suit.

50.1 Bending the first bend of the switch

operating wire

50.2 Open out the hole in the switch to

suit the wire

51. Place the backing plate of the switch

over the remaining rectangular hole in the

servo tray and use it to drill two, 2mm

holes for the switch mounting. Pass the

switch from the underneath into the tray

hole, add the backing plate and secure in

place with the two screws supplied.

Drill a suitable hole for the operating arm

wire in the fuselage side in line with the

switch side.

52. On the other end of the wire make a 45

degree bend, facing towards the rear of the

model, to form a grip. Pass the wire

through the fuselage side and thread the 90

degree bend into the hole in the switch.

The wire is prevented from becoming

detached by gluing a repair piece of wood

onto the tray, allowing it to rest against the

wire. Ensure the switch operates

smoothly and that it follows convention by

arranging the operating arm to push for 'on'

51.1 Using the switch backing plate to

drill the two mounting holes

51.2 Drilling fuselage side for ^

operating arm in line with switch side

52.1 45 degree bend formed on other

end of wire

52.2 Scrap piece of wood glued to tra

to prevent the operating arm becomir

detached

Loading...

Loading...