Trainer 40 Instructions

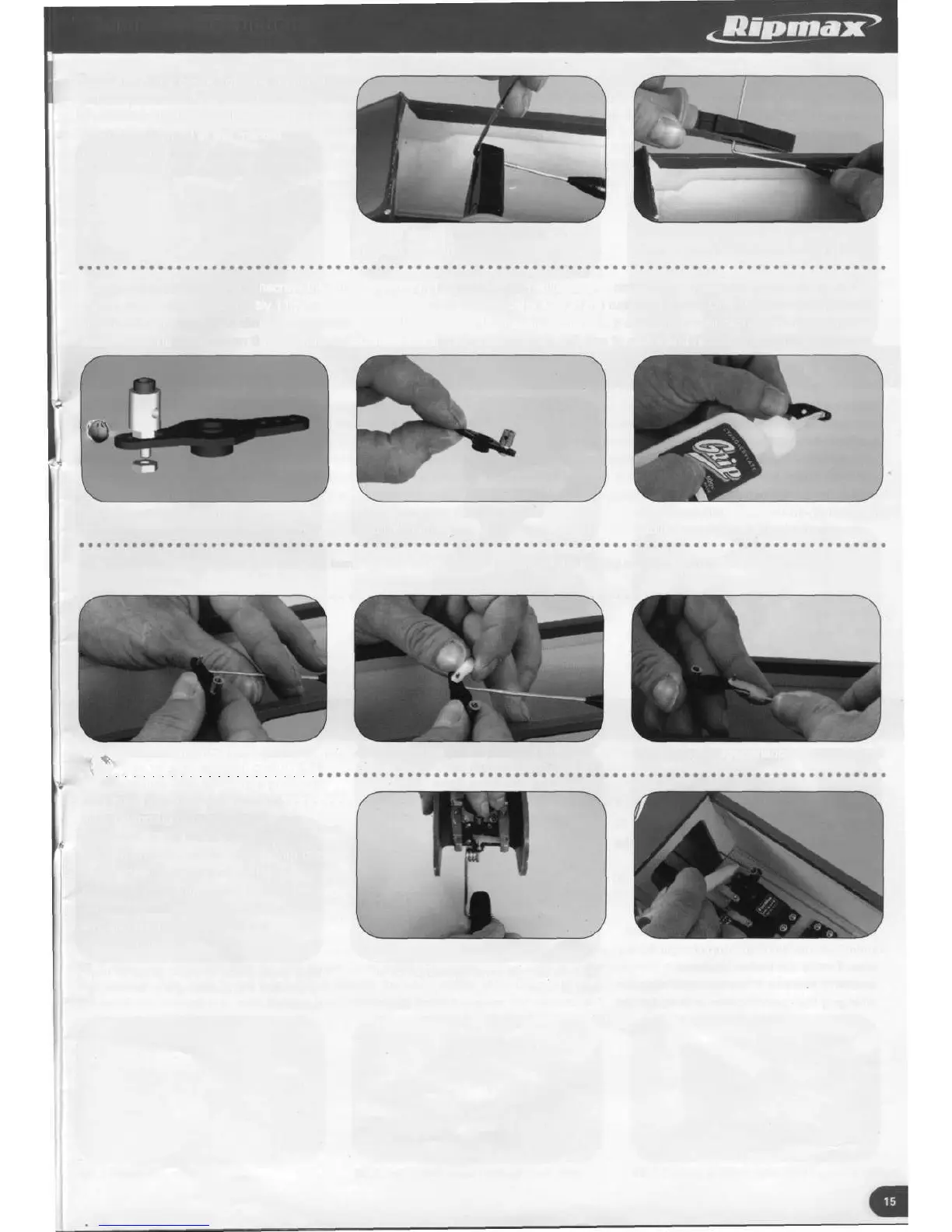

45. Release the clevis from the horn and

pull the pushrod clear from the fuselage

a sufficient distance to allow a 90 degree

bend to be formed at the marked

position. Cut off any excess wire to

leave 6mm of pushrod after the bend.

45.1 90 degree bend formed at

marked position

45.2 Cut off excess wire to leave

6mm of pushrod beyond the bend

46. Remove the servo arm. Unscrew the grub screw from the centre of an adjustable connector and attach the connector to the

rudder servo arm approximately 11mm from the centre and on the opposite side to the rudder pushrod. Only tighten the screw into

the first nut an amount to allow the connector to freely rotate and then apply a small drop of medium cyanoacrylate and add the

second lock nut and tighten the two nuts together. Check that the connector is still free to rotate and replace the central grubscrew.

46.1 Connector illustration

46.2 Connector fitted to rudder

control horn

46.3 Small drop of medium cyanoacrylate

applied together with locknut

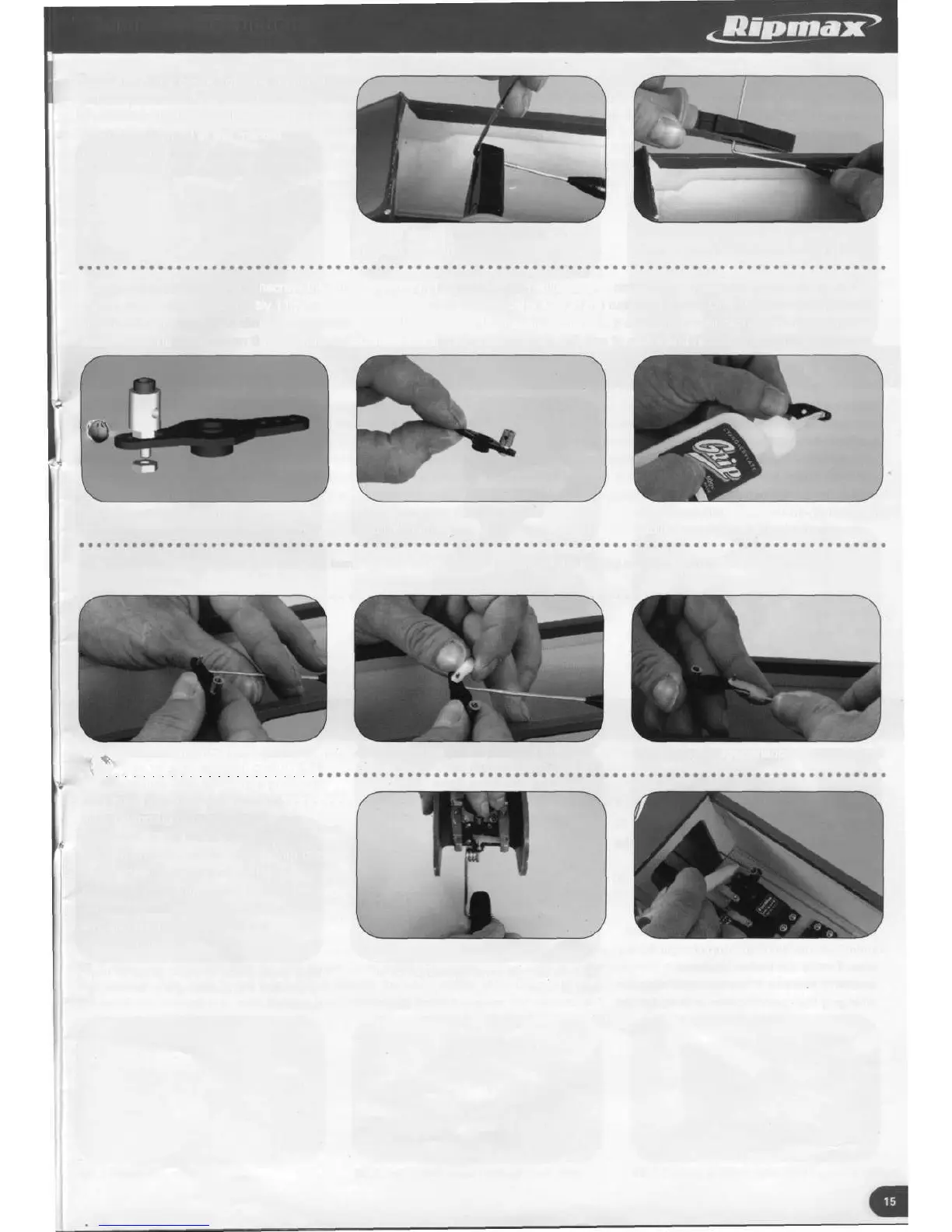

47. Thread the rudder servo arm over the bend formed on the rudder pushrod followed by a swing keeper, snapping the

keeper into place.

47 J Servo arm threaded onto pushrod

..#

47.2 Swing keeper in place on pushrod

47.3 Swing keeper snapped over pushrod

48. Thread the steerable nose leg

pushrod through the adjustable

connector, at the same time replacing

the arm onto the rudder servo. With the

nose wheel held centred, mark the

pushrod at a position 8mm beyond the

adjustable connector. Remove the servo

arm and cut the pushrod to the

marked line.

48.1 Nose wheel held centred 48.2 Marking nose leg pushrod position

Loading...

Loading...