Rite-Hite

®

Installation/Service/Owner's Manual PitMaster™ II Under-leveler Seal

Publication: AMEN00401 2021-04-02 9

TROUBLESHOOTING

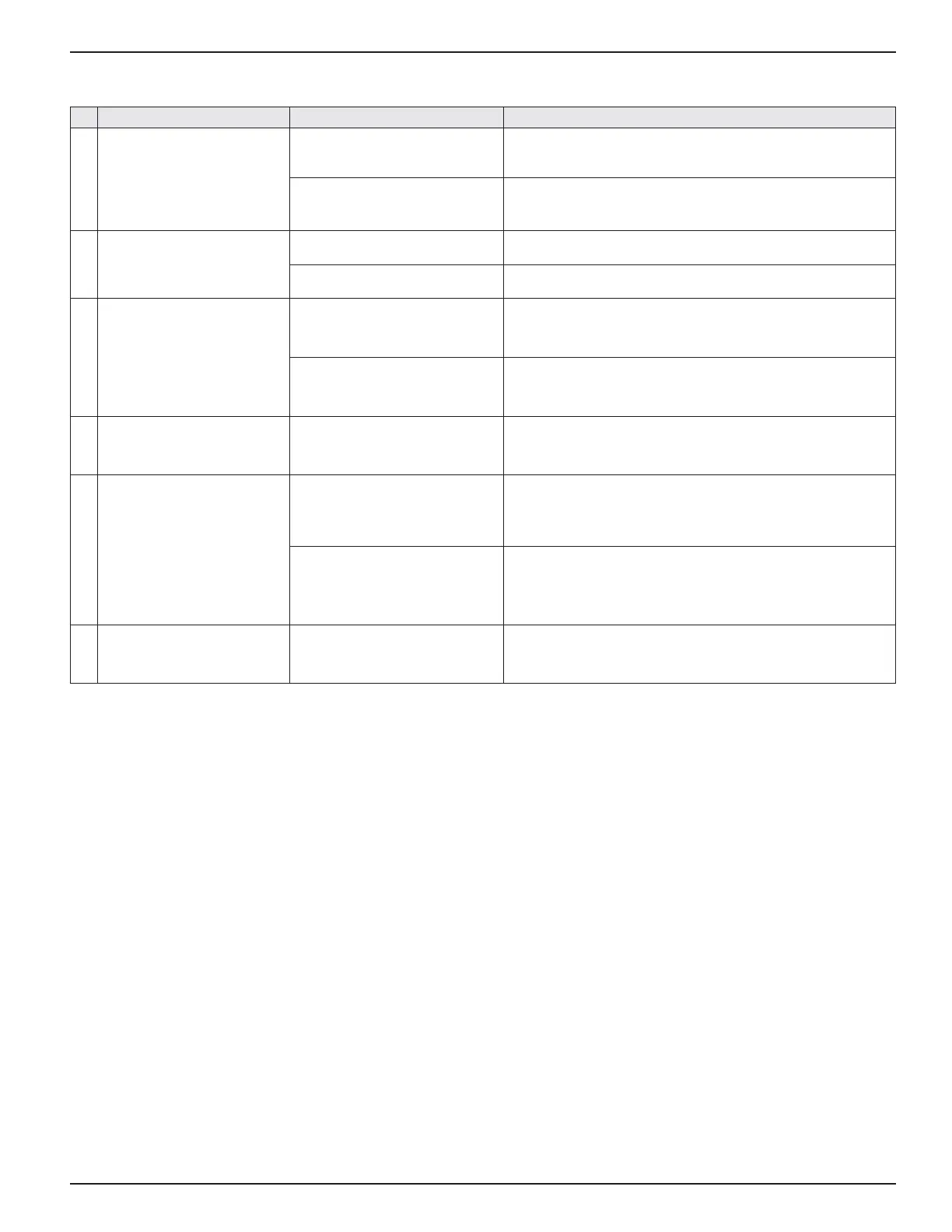

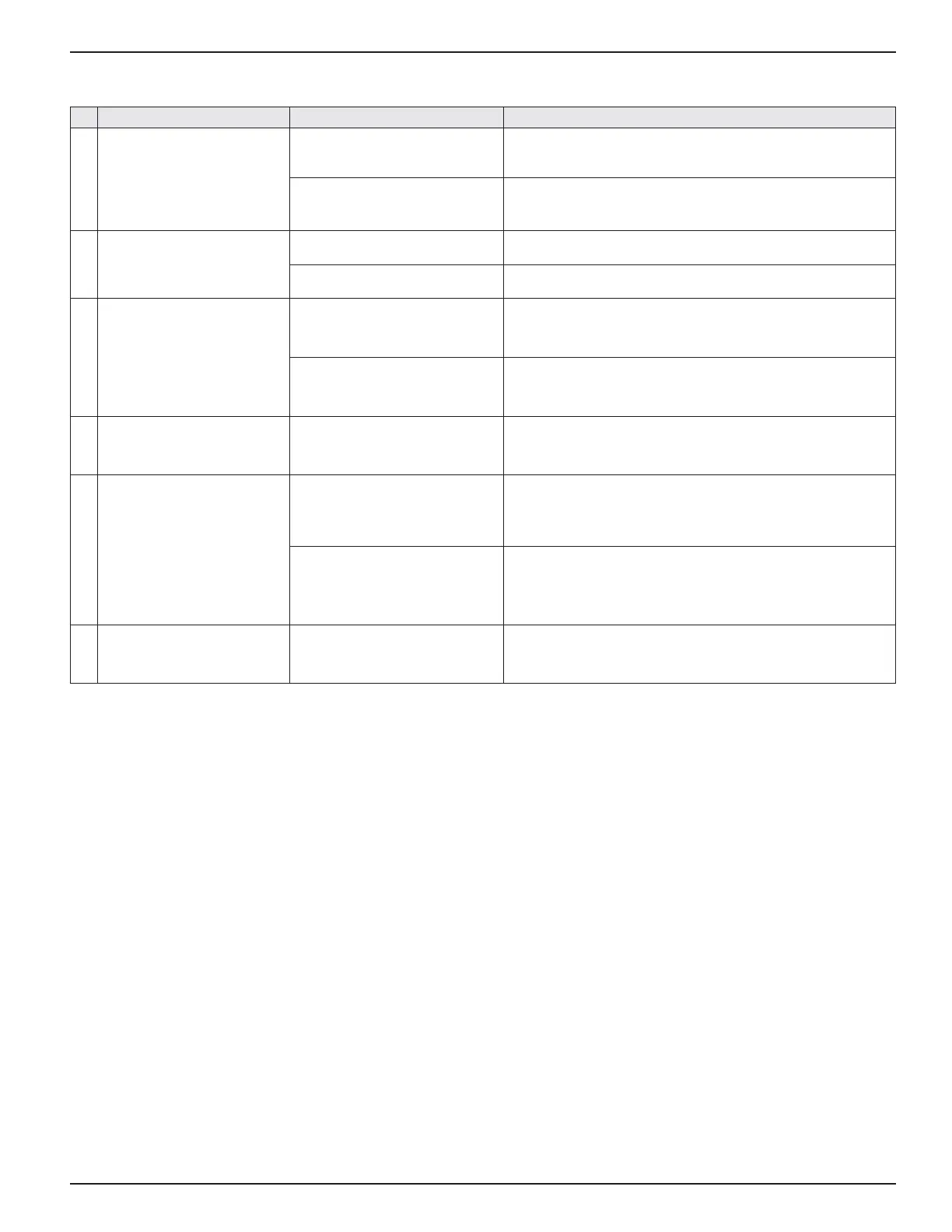

#

ISSUE POSSIBLE CAUSE(S) SOLUTION

1 The curtain sags and/or falls

into the pit after the leveler has

stored.

The hook and loop fastener has

come loose between the main

curtain and the top section.

Re-attach the hook and loop fastener from the middle out. Make

sure the main curtain is evenly spaced and rmly pressed to the top

section.

One or more of the spring clips has

detached or broken from the leveler

frame.

Examine the spring clip to determine if it can be remounted.

Remount or if spring clip is broken, contact Rite-Hite Environmental

Enclosures Parts Department for replacements.

2 The width of the main curtain

and top section are not the

same width as the leveler.

Main curtain and top section may be

misapplied or on the wrong leveler.

Make sure components are being applied to the correct leveler. If

correct, re-apply and evenly space the main curtain and top section.

Main curtain and top section are

wider than the leveler.

Make sure components are being applied to the correct leveler. If

correct, trim edges of each for a better t.

3 The unit is not sealing the sides

of the pit well.

The side seals may be damaged. Check if the side seals have been bent or torn from the wall. They

can be reattached with concrete anchors (supplied by others) or

new side seals can be purchased from Rite-Hite Environmental

Enclosures Parts Department.

The side seals may be the wrong

height.

The side seals come in 16 in (406 mm), 24 in (610 mm) or 34 in

(854 mm) heights and are trimmed to t the pit. Side seals that are

too tall of can be trimmed for a better t. Side seals that are too short

need to be replaced.

4 The toe guards, safety legs,

end load legs, or other obstacles

hit the curtain when leveler is

coming down.

This is normal contact between

parts. The main curtain and top

section are designed to move and

ex with the leveler components.

The PitMaster II is reinforced to allow safety or end load legs to

perform their function without major wear or damage to the main

curtain or top section. It is normal to see some discoloration or wear

on the curtain from these legs.

5 The safety or end load legs are

pulling o the curtain or are

wearing through the curtain.

The building may have high positive

pressure or the main curtain may

not be folding properly when the

leveler moves.

Make sure there is enough tension on the shock cord connected

to the back of the main curtain and the leveler stringers. The shock

cords should be pulled tight and not sagging The spring clips on

the leveler stringers may need to be moved further into the pit to

increase tension.

The building may have high

negative pressure and is pushing

the main curtain too far into the pit.

When there is a high negative pressure, the bottom aps of the main

curtain can be attached to the ller panels or front of the pit. This

prevents the main curtain from pushing too far into the pit.

Refer to

"Non-Standard Levelers" on page 3 for more

information or contact Rite-Hite Applications.

6 Bottom of main curtain catches

on lip keepers or subframe.

The bottom of the main curtain may

not be trimmed correctly.

The main curtain has aps at the bottom which need to be trimmed

to correctly t and seal around pit obstructions. Make sure all 3

layers of aps have been separated to ll in the space around the

subframe. Trim any that are catching.

Loading...

Loading...