(1) Tap end of crankshaft slightly to shoulder shaft against main bearing at flywheel end.

(2)

Use a depth gauge and straight edge to measure the distance between the machined surface

of the crankcase

(A)

and the crankshaft gear surface

(B).

Record this as measurement 1.

e

(3) Measure the distance between the machined face of the main bearing cover

(C)

and the outer

surface of the main bearing’s inner race

(D)

(EH30V

and EH34V).

For

EH43V, use outer surface

of boss for the plane metal bearing. Record this

as

dimension 2.

(4) The compressed thickness

of

the crankcase cover gasket

is

0.26mm (0.Olin.). Record this

as

dimension

3.

(5)

Subtract dimension 1 from dimension

2

and then add dimension

3.

The result will be the

final dimension. Choose an adjusting shim that is 0-0.2mm (0-0.008in.) less than the final

dimension.

(6)

Tap end of camshaft slightly to shoulder shaft against bearing in crankcase.

(7)

Use

a

depth gauge and straight edge to measure the distance between the machined surface

of the crankcase

(A)

and the camshaft thrust surface

(E).

Record this

as

measurement 4.

(8)

Measure the distance between the machined face of the main bearing cover

(C)

and the outer

surface of the cam bearing thrust

(F).

Record this as dimension

5.

(9)

Use the crankcase cover gasket dimension recorded earlier as dimension

3.

(10) Subtract dimension 4 from dimension

5.

Add dimension

3.

The result will be the final

dimension. Choose an adjusting shim that is 0.13-0.29mm (0.005-0.011in.) less than the finafl

dimension for

EH30V

and EH34V.

Choose an adjusting shim that

is

0.13-0.39mm (0.005-0.015in.l less than the final dimension

for EH43V.

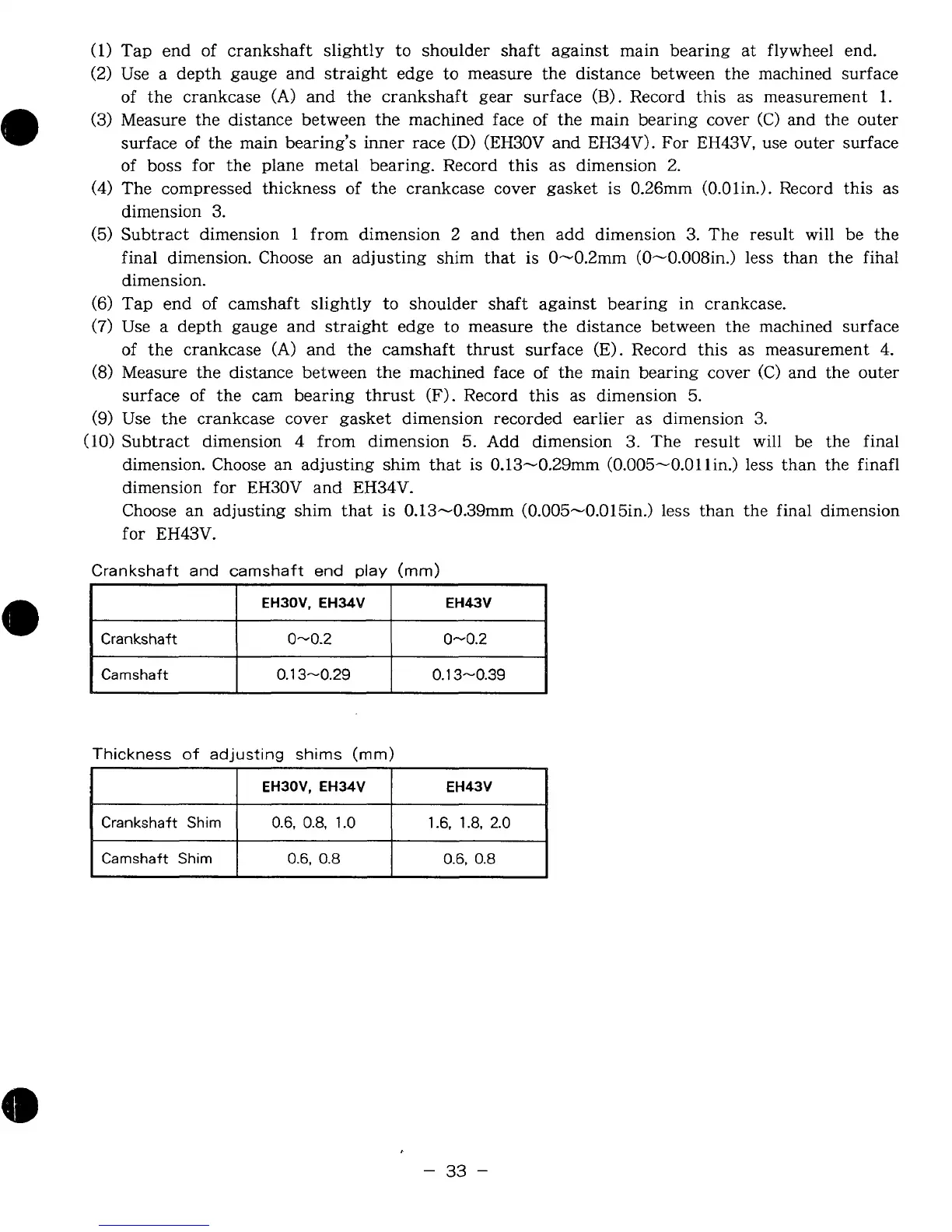

Crankshaft and camshaft end play

(mm)

I

I

EH30V, EH34V

I

EH43V

I

I

Crankshaft

1

0-0.2

Camshaft

0.1

3-0.39

0.1

3-0.29

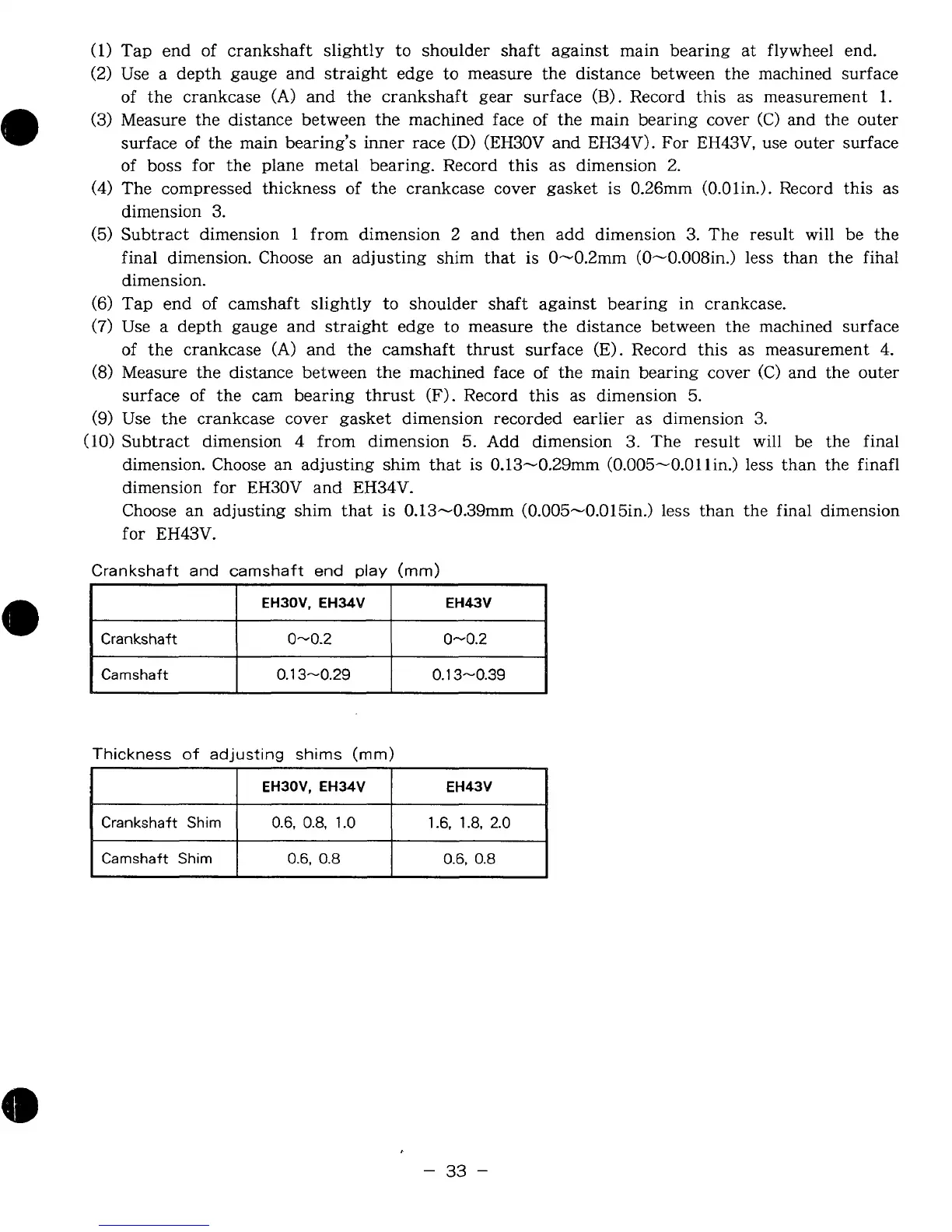

Thickness

of

adjusting

shims

(rnm)

EH30V, EH34V EH43V

Crankshaft Shim

0.6,

0.8,

1.0

1.6.

1.8,

2.0

Camshaft Shim

0.6,

0.8

0.6,

0.8

-

33

-

Loading...

Loading...