3)

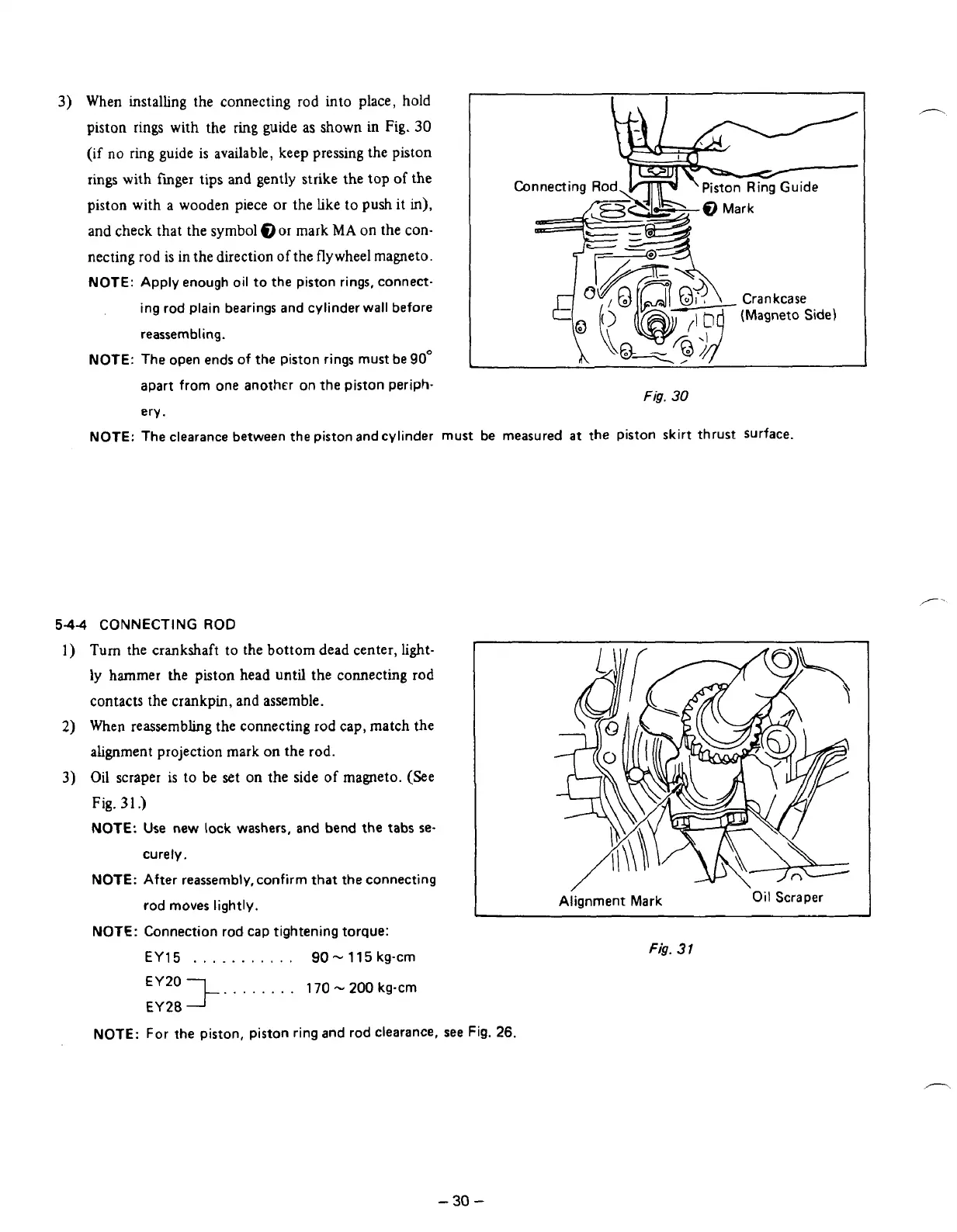

When installing the connecting rod into place, hold

I

piston rings with the

ring

guide

as

shown in Fig.

30

(if

no

ring guide is available, keep pressing the piston

rings with finger tips and gently strike the top

of

the

piston with a wooden piece

or

the like

to

push

it in),

and check that the symbol

@or

mark

MA

on the con-

necting rod is in the direction

of

the flywheel magneto.

NOTE:

Apply enough oil

to

the piston rings, connect-

ing

rod

plain bearings and cylinder wall before

reassembling.

NOTE:

The open ends

of

the piston rings must be

90"

apart from one another

on

the piston periph-

Piston

Ring Guide

Fig.

30

ery

.

NOTE:

The clearance between the piston and cylinder must be measured

at

the piston skirt thrust surface.

544

CONNECTING

ROD

1)

Turn

the crankshaft to the bottom dead center, light-

ly

hammer the piston head

until

the

connecting

rod

contacts the crankpin, and assemble.

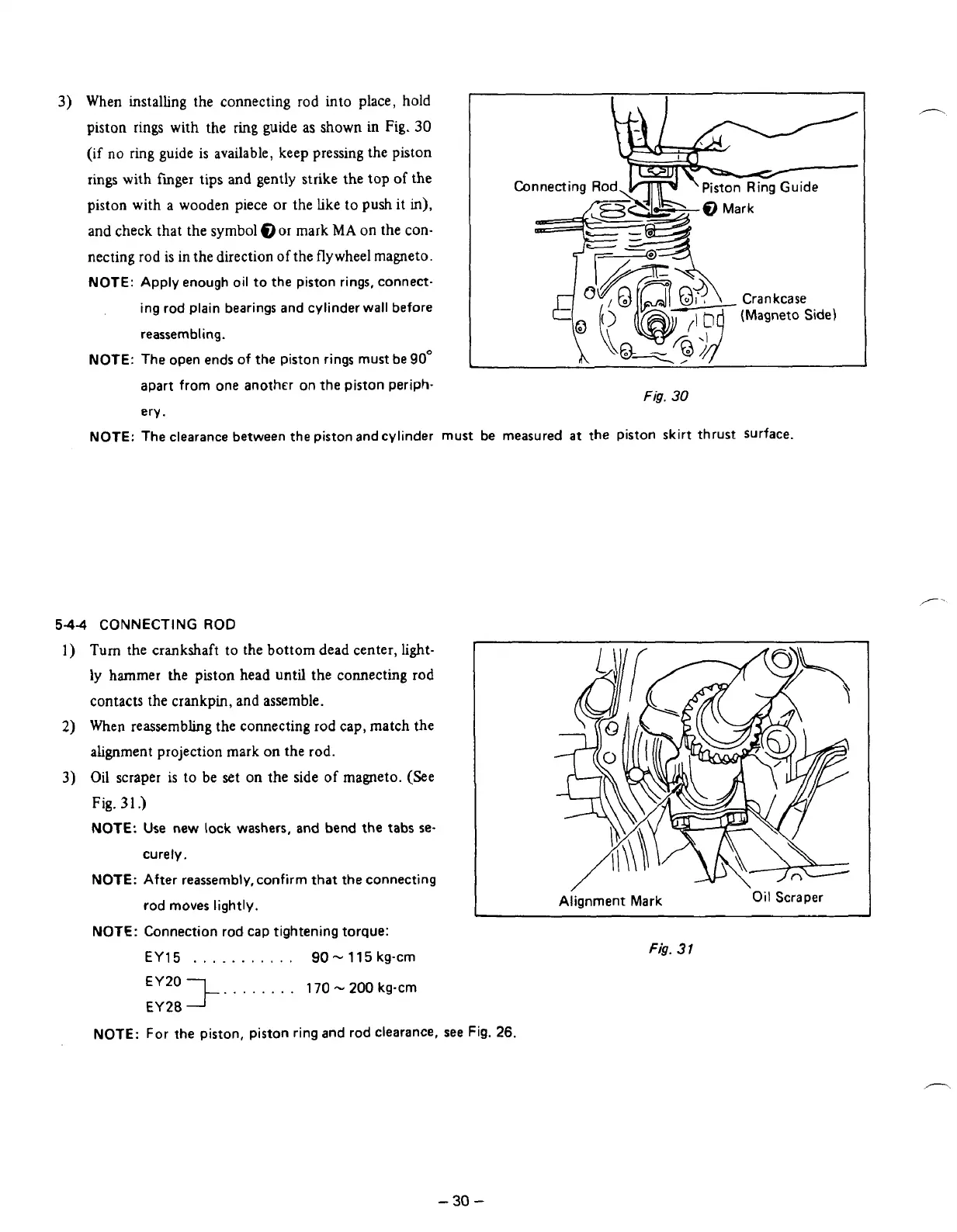

2)

When reassembhg the connecting

rod

cap, match the

alignment projection mark on the

rod.

3)

Oil scraper

is

to be set on the side

of

magneto. (See

Fig.

31

.)

NOTE:

Use new lock washers, and bend the tabs se-

curely.

NOTE:

After reassembly, confirm that the connecting

rod moves lightly.

NOTE:

Connection rod cap tightening torque:

EY15

.

,

.

.

. .

.

.

.

.

.

90-

115

kg-cm

. .

. . .

.

.

.

170

-

200

kg-cm

EY20

+-

EY28

I

Alignment

Mark

Oil

Scraper

Fig.

31

NOTE:

For the piston, piston ring and rod clearance, see Fig.

26.

-

30

-

Loading...

Loading...